A chamfer machine is a machine tool that is used to create a chamfer, which is a beveled edge on a workpiece. The chamfer machine can be used to create chamfers on a range of materials, including metal, plastic, and wood.

The chamfer machine works by rotating the workpiece and using a cutting tool to create the chamfer. The machine can be equipped with various types of cutting tools, including milling cutters, grinding wheels, and abrasive discs. Some chamfer machines can also be programmed with a computer numerical control (CNC) system, allowing for more precise control over the chamfering process.

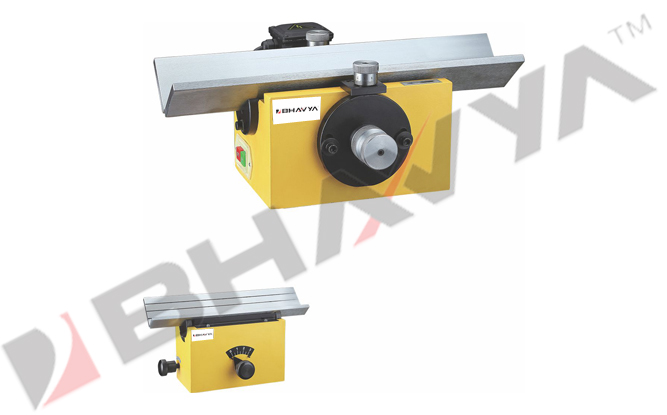

Chamfer machines come in a variety of sizes and styles, from small handheld devices to large industrial machines. Some chamfer machines are designed for use in a production line, while others are more suitable for use in a workshop or laboratory.

Chamfer machines are commonly used in the manufacturing industry to create chamfers on a range of products, including gears, shafts, and machine parts. Chamfering the edges of these parts helps to reduce stress concentrations and improves their overall strength and durability.

Some of the key features of chamfer machines include:

- Versatility: Chamfer machines can be used to create chamfers on a range of materials, making them suitable for use in a variety of industries.

- Precision: The machine can be programmed to create chamfers with high precision and accuracy, ensuring that the chamfers meet the required specifications.

- Efficiency: Chamfer machines can create chamfers quickly and efficiently, reducing the time required for manual chamfering.

- Consistency: Chamfer machines can create chamfers that are consistent in size and shape, improving the quality of the finished product.

Sliding Chamfer:

A sliding chamfer is a type of chamfer that is created by a sliding chamfer tool. The tool is designed to slide along the edge of a workpiece, gradually removing material to create a beveled edge or chamfer.

Sliding chamfers are commonly used in the manufacturing industry to create chamfers on a range of materials, including metal, plastic, and wood. The sliding chamfer tool can be used to create chamfers of varying sizes and angles, depending on the specifications of the workpiece.

Some of the key features of sliding chamfers include:

- Precision: Sliding chamfers can be created with high precision and accuracy, ensuring that the chamfers meet the required specifications.

- Flexibility: The sliding chamfer tool can be adjusted to create chamfers of varying sizes and angles, making it suitable for use in a variety of industries.

- Efficiency: Sliding chamfers can be created quickly and efficiently, reducing the time required for manual chamfering.

- Consistency: Sliding chamfers can create chamfers that are consistent in size and shape, improving the quality of the finished product.

Overall, sliding chamfers are an essential tool for any manufacturing facility that requires the creation of chamfers on a range of materials. Their precision, flexibility, efficiency, and consistency features make them an important part of the production process, helping manufacturers improve productivity and quality while reducing costs.

Complex Chamfer

A complex chamfer is a chamfer that is created on a workpiece with a complex shape or geometry. Unlike a simple chamfer, which is created by removing material from a straight edge, a complex chamfer requires the use of specialized tools and techniques to create a beveled edge that follows the contours of the workpiece.

Complex chamfers are commonly used in the manufacturing industry to create chamfers on parts with complex shapes, such as gears, turbine blades, and engine components. The creation of complex chamfers requires specialized tools and techniques, such as CNC machining and five-axis milling, to ensure that the chamfer follows the contours of the workpiece accurately.

Some of the key features of complex chamfers include:

- Precision: Complex chamfers require high precision and accuracy to ensure that the chamfer matches the shape and geometry of the workpiece.

- Specialized tools: The creation of complex chamfers requires specialized tools and techniques, such as CNC machining and five-axis milling.

- Efficiency: While the creation of complex chamfers can be time-consuming, specialized tools and techniques can help to reduce the time required for manual chamfering.

- Improved strength: Complex chamfers can help to reduce stress concentrations on parts with complex shapes, improving their overall strength and durability.

Overall, complex chamfers are an important part of the manufacturing process for parts with complex shapes or geometries. Their precision, specialized tools, efficiency, and improved strength features make them an essential tool for any manufacturing facility that requires the creation of chamfers on complex workpieces.

Portable Chamfer

A portable chamfer is a chamfering tool that can be easily moved from one location to another. Portable chamfers are designed to be lightweight and compact, making them ideal for use in the field or on job sites where a fixed chamfering machine may not be practical.

Portable chamfers come in a variety of sizes and shapes, ranging from handheld tools to larger machines that can be transported on a trailer or truck. They are typically powered by electricity or battery, and some models may also include a pneumatic or hydraulic system for additional power.

Some of the key features of portable chamfers include:

- Versatility: Portable chamfers can be used on a variety of materials, including metal, plastic, and wood.

- Ease of use: Portable chamfers are designed to be easy to use, even for novice operators.

- Portability: Portable chamfers can be easily moved from one location to another, making them ideal for use in the field or on job sites.

- Efficiency: Portable chamfers can create chamfers quickly and efficiently, reducing the time required for manual chamfering.

Overall, portable chamfers are an important tool for any manufacturer or contractor that requires the creation of chamfers in the field or on job sites. Their versatility, ease of use, portability, and efficiency features make them an essential tool for any operation that requires the creation of beveled edges or chamfers.

Arch Angle Chamfer

An arch angle chamfer is a type of chamfer that is created on an arch-shaped workpiece or part. The chamfer is created by removing material from the edge of the arch, resulting in a beveled edge or angled surface.

Arch angle chamfers are commonly used in the manufacturing industry to create beveled edges on a variety of arch-shaped parts, such as gears, shafts, and curved components. The creation of arch angle chamfers requires specialized tools and techniques, such as CNC machining and five-axis milling, to ensure that the chamfer is created accurately and precisely.

Some of the key features of arch angle chamfers include:

- Precision: Arch angle chamfers require high precision and accuracy to ensure that the chamfer matches the curvature of the arch-shaped workpiece.

- Specialized tools: The creation of arch angle chamfers requires specialized tools and techniques, such as CNC machining and five-axis milling, to ensure accuracy and precision.

- Strength and durability: Arch angle chamfers can help to reduce stress concentrations on arch-shaped parts, improving their overall strength and durability.

- Improved aesthetics: Arch angle chamfers can improve the aesthetics of arch-shaped parts by creating a smooth, beveled edge.

Overall, arch angle chamfers are an important part of the manufacturing process for arch-shaped parts or components. Their precision, specialized tools, strength and durability, and improved aesthetics features make them an essential tool for any manufacturing facility that requires the creation of beveled edges on arch-shaped parts.

Chamfer machine is an essential tool for any manufacturing facility that requires the creation of chamfers on a range of materials. Its versatility, precision, efficiency, and consistency features make it an important part of the production process, helping manufacturers improve productivity and quality while reducing costs.