What is an Ironworker?

An Ironworker is a category of machines that can cut, mark, and punch holes in metal plates. The term refers to the entire mechanical category. If there had ever been a brand name, now it has become a trademark. Metalworkers generate energy using the advantages of machinery or compression systems.

The basic hydraulic transmission principle is used in these machines. It states that: The hydraulic system uses a hydraulic pump to convert the prime mover’s mechanical power into the liquid pressure. The force is transmitted through a fluid pressure change of liquid and is transmitted through various control pipes and pipes. The heater (cylinder or motor) converts the compression force of electricity into electrical energy, thus driving the process of achieving the corresponding motion of rotation and rotational motion. This Hydraulic Ironworker is a machine that uses hydraulic transmission as a lifting force.

Hydraulic transmission is a transfer method that uses fluid as an active function to transfer energy and control it. It is a rising innovation created dependent on the hydrostatic weight transmission standard proposed by Pascal in the seventeenth century. It is an innovation regularly utilized in mechanical and agricultural creation.

Different Types of Ironworker

One operator:

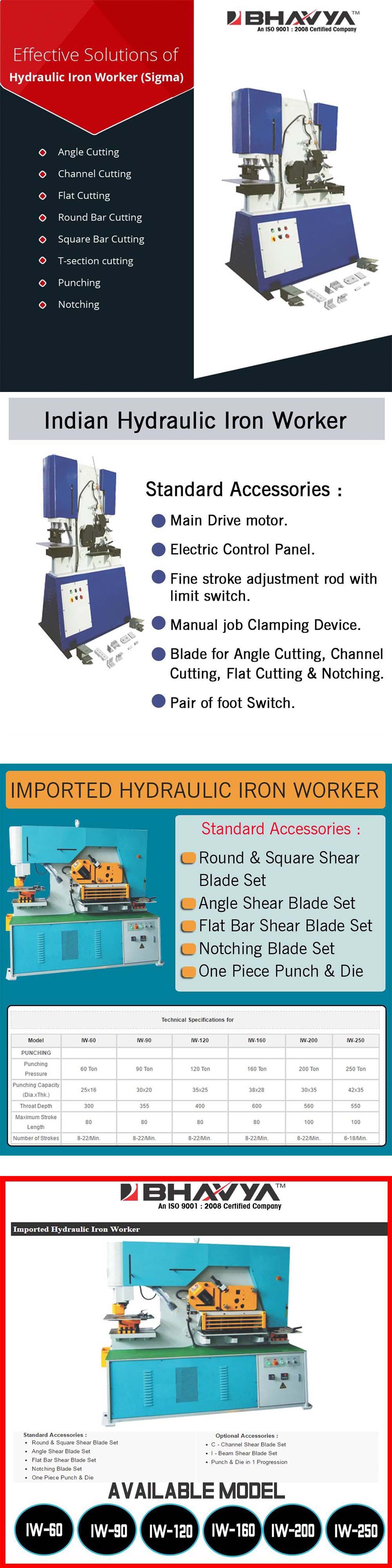

In Hydraulic Iron Worker (Sigma), only one person can use any of the tool channels simultaneously. These types of metalworkers are more common in small stores and, in many cases, occupy space even less than two operator units.

Dual operators:

Hydraulic Ironworker machines provide additional power for more than one operator to operate other channels, other than the piercing station simultaneously. This performance increases the productivity and efficiency of the machine which further leads to maximize the production of the store. Dual operator power is obtained by installing a second cylinder and a pump. One cylinder will enable the call center, and the other cylinder will enable other tool channels.

Two operator units are slightly more expensive yet beneficial than a single operator unit; however, the higher product is quickly eliminated.

Industrial Applications of Ironworker

Hydraulic Ironworker comes with a wide range of applications and works for many industries including tower manufacturing, Bridge construction, and production, and also the Telecommunication industries. Other than that, these are used in reshaping the iron structures like cutting and refining angles, punching, beating, I-section, circular, channels, bending.

Benefits of Ironworker

Ironworkers are well-designed, build with steel for high strength, top quality, and reliability. These machines have two-foot control nails, and the various functions can be safely performed simultaneously without interruption. The Ironworkers series generally include repetitive support punch, shear and notch station tables, and flexible grip on all five-work stations to manage tasks securely. Perfect guards are deployed as usual in all workstations. Freestanding on the right floor with the help of an electrical connection that makes it ready for operation.

The liquid in machines is called moderate action, and it is usually mineral oil. Its function is similar to that of transmitters such as belts, chains, and gears in equipment transfer. Only because of these benefits of hydraulic transmission, drilling rig, and cutting machine, Ironworkers works on hydraulic technology and it makes these machines a beast of the industry. With compression pressure, the machine has high strength, safe operation, low weight, low noise, high efficiency, cost savings, and cutting areas. Hydraulic Ironworkers are the machines with the latest technology. Hence, they can prove to be the best option for your industry. With minimum efforts, these can give maximum output. Updated features make them easy to handle and require very few human resources for operation. As said, ironworker is useful in innumerable industries from construction to telecommunication. And for someone working there, this machine can be a real gem.