Objective of the Article

The objective of this article is to provide a detailed comparison and selection process for bed-type milling machines. It aims to assist manufacturers and workshop managers in understanding the differences between various milling machine types, including bed-type, knee-type, and planer-type mills, as well as the advantages and disadvantages of CNC versus manual bed-type machines. The article also explores factors that influence the selection of the right bed-type milling machine, focusing on key aspects such as precision, power, performance, and the specific needs of the workshop. Additionally, it compares different machine brands, cutter tools, and table sizes to help users make informed decisions based on their unique operational requirements.

Bed Type vs. Knee Type vs. Planer Type Milling Machines: Which to Choose?

When selecting a milling machine, understanding the differences between bed-type, knee-type, and planer-type machines is crucial.

- Bed Type Milling Machines: These are best suited for heavy-duty, high-precision, and large workpieces. The table moves in the X and Y axes, and the spindle moves vertically. This design is ideal for large, complex parts and batch production.

- Knee Type Milling Machines: These are more versatile and typically used for smaller parts and lighter operations. The table can be raised or lowered on the vertical column, offering more flexibility in handling various workpiece sizes.

- Planer Type Milling Machines: These are used for machining very large parts or very long workpieces. The table can move in both horizontal and vertical directions, making them ideal for operations requiring substantial flexibility in part movement.

The choice between these machines depends on the type of workpiece, production volume, and required precision. Bed-type mills are generally preferred for high-precision, high-volume operations on large components.

What Our Customers Say

“My items arrived well packaged and in perfect condition.” “The quality of the products exceeds my expectations every time. “Trusted industry company. Their product is of the highest quality, and their commitment to sustainability is admirable. ”

Procurement RGI On Google

CNC Bed Type Milling Machine vs. Vertical Machining Center: A Detailed Comparison

While both CNC Bed Type Milling Machines and Vertical Machining Centers (VMCs) offer automated milling solutions, they have distinct differences:

- CNC Bed Type Milling Machines: These machines offer high precision for large workpieces with heavy cutting capacities. They are ideal for applications where rigidity and stability are paramount. CNC technology allows for automated machining, improving efficiency for complex and high-precision tasks.

- Vertical Machining Centers (VMCs): VMCs are more versatile in terms of movement, offering higher flexibility for small to medium-sized parts. They are suitable for jobs that require multiple axes of movement and often feature rotary tables for 5-axis milling.

The decision between these two machines largely depends on the scale of the operation and the types of parts being produced. CNC bed-type mills are typically better for large, heavy components, while VMCs are more suitable for smaller, high-precision jobs.

How to Choose the Right Bed Type Milling Machine for Your Workshop

Choosing the right bed-type milling machine involves considering several key factors:

- Workpiece Size and Weight: Ensure the machine can accommodate your largest workpiece.

- Precision Requirements: Determine the tolerance levels required for your parts.

- Production Volume: If you plan on high-volume production, opt for a machine with automated CNC capabilities.

- Material Compatibility: Consider the materials you’ll be working with—harder materials require machines with more robust cutting capabilities.

- Machine Size and Space: Measure your available space to ensure the machine fits within your workshop.

- Budget: Factor in not only the machine’s initial cost but also long-term maintenance and tooling expenses.

By understanding these aspects, you can select a bed-type milling machine that best suits your workshop’s specific needs.

Factors to Consider When Buying a Bed Type Milling Machine

When purchasing a bed-type milling machine, consider the following:

- Power and Torque: High-power motors and torque ensure that the machine can handle tough materials and larger workpieces.

- Precision: Look for machines with high rigidity and accurate controls.

- Speed and Efficiency: Machines with higher cutting speeds can improve productivity, especially in batch production.

- Automation: CNC options can increase efficiency and consistency for high-volume production.

- Ease of Maintenance: Machines that are easier to maintain will lower downtime and operational costs.

- Manufacturer Support and Warranty: Ensure that spare parts and technical support are readily available.

Comparing Manual and CNC Bed Type Milling Machines

- Manual Bed Type Milling Machines: These are typically simpler machines with a manual control interface. They are cost-effective and ideal for smaller operations or shops that only require low-volume production and flexibility in machining.

- CNC Bed Type Milling Machines: These machines incorporate computer numerical control for automated operation. CNC bed-type mills are highly precise and capable of performing complex, high-volume tasks with minimal human intervention. They are suited for industries requiring high levels of automation, repeatability, and consistency.

The choice between manual and CNC versions depends on the complexity of your operations and the level of automation you need.

Bed Type Milling Machine vs. Gantry Milling Machine: Which Offers Better Precision?

Both bed-type milling machines and gantry milling machines are designed for large workpieces, but there are key differences:

- Bed Type Milling Machines: Offer better precision for operations involving smaller to medium-sized workpieces, as the rigid structure of the machine ensures minimal vibration and maximum stability.

- Gantry Milling Machines: Often used for much larger parts and provide better flexibility in terms of machine movements. They can offer high precision, but the setup is generally more complex, and they are best for very large-scale projects.

For most precision jobs involving large, complex parts, a bed-type milling machine will offer better results due to its stability and reduced setup time.

Evaluating European vs. Asian Brands of Bed Type Milling Machines

When selecting a bed-type milling machine, the brand can impact both quality and cost:

- European Brands: Typically known for their high-quality, precision engineering, European brands often come with superior features and robust customer support. However, they tend to be more expensive.

- Asian Brands: Offer more cost-effective solutions with competitive performance. While they may not always match the precision levels of European machines, many Asian brands are now manufacturing machines that come close to their European counterparts, making them ideal for budget-conscious manufacturers.

Ultimately, the choice depends on the balance of cost, required precision, and long-term investment.

Power, Precision, and Performance: Top Features to Look for in Bed Type Mills

When choosing a bed-type milling machine, consider these top features:

- Spindle Power: High-power spindles are essential for handling tough materials.

- Precision: Look for machines with high repeatability and minimal thermal deformation.

- Feed Rate: Faster feed rates can improve production time but should not compromise on precision.

- Table Size: Ensure the table is large enough to support your workpieces.

- Coolant System: A reliable coolant system will prevent overheating and ensure the longevity of your cutting tools.

How Machine Table Size Affects Productivity in Bed Type Milling

The size of the machine table plays a critical role in productivity. A larger table can handle bigger workpieces, reducing the need for repositioning and increasing efficiency. However, larger tables can also increase the machine’s footprint and cost. Selecting the appropriate table size based on your workpiece dimensions is key to optimizing productivity.

Selecting the Best Cutter Tools for Bed Type Milling Operations

Choosing the right cutter tools is essential for maximizing the performance of your bed-type milling machine. Factors to consider include:

- Material Compatibility: Choose cutter tools made from materials compatible with your workpiece material, such as carbide tools for hard metals.

- Tool Geometry: Ensure the tool geometry matches the type of operation (e.g., face milling, end milling).

- Tool Life: Select tools with extended life to reduce operational downtime and improve cost efficiency.

Conclusion

Selecting the right bed-type milling machine for your operations requires careful consideration of various factors, including workpiece size, precision requirements, and machine type. By understanding the differences between bed-type mills, CNC options, and other milling machines, you can make an informed decision that improves both productivity and quality in your workshop.

FAQS on Bed Type Milling Machine

What is a bed-type milling machine used for?

A bed-type milling machine is primarily used for heavy-duty milling operations, particularly for machining large and heavy workpieces. It offers high precision and stability, making it ideal for applications in industries such as aerospace, automotive, energy, and heavy machinery manufacturing. It’s often used for operations like face milling, slot milling, and precision part manufacturing.

How does a bed-type milling machine differ from a knee-type milling machine?

The key difference is in the movement of the table. In a bed-type milling machine, the table is stationary, and the saddle and column move in both the X and Y directions, while the spindle moves vertically. In contrast, a knee-type milling machine has a table that can be raised or lowered on a column, allowing for more flexibility in part height adjustments. Bed-type mills are more rigid and suited for heavy-duty tasks, whereas knee-type mills are more versatile for smaller parts.

Can a bed-type milling machine handle large workpieces?

Yes, one of the primary advantages of a bed-type milling machine is its ability to accommodate large workpieces. The machine’s rigid construction and large table size allow it to handle heavy and oversized components, making it ideal for industries that require precision in machining large, complex parts.

What are the advantages of a CNC bed-type milling machine over a manual one?

A CNC bed-type milling machine offers several advantages over manual machines, including:

- Automation: CNC machines reduce manual labor and can operate continuously, improving efficiency.

- Precision: CNC control ensures high precision and repeatability in machining.

- Complexity: CNC machines can easily handle complex geometries and multi-axis movements.

- Consistency: They provide consistent quality, making them ideal for high-volume production runs.

What types of industries use bed-type milling machines?

Bed-type milling machines are used across a variety of industries, including:

- Aerospace: For machining large, high-precision components.

- Automotive: To produce parts such as engine blocks, transmission housings, and suspension components.

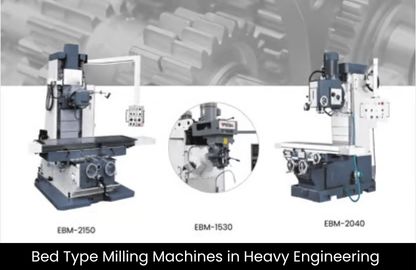

- Heavy Engineering: For manufacturing large components in construction and industrial machinery.

Energy: For making parts in power generation equipment like turbines and valves.

How does the table size affect a bed-type milling machine's performance?

The table size directly influences the machine's capacity to handle larger workpieces. A larger table allows for bigger parts, reducing the need for repositioning, which can improve efficiency. However, a larger table may also require more space and come at a higher cost. The ideal table size depends on the size of the workpieces and the space available in your workshop.

What are the key features to look for when buying a bed-type milling machine?

When purchasing a bed-type milling machine, look for:

- Spindle power and speed: To handle tougher materials and achieve faster cutting.

- Table size: To ensure it fits your workpieces.

- Precision and rigidity: For maintaining tight tolerances and ensuring accuracy.

- Automation: CNC capabilities for reducing manual intervention and increasing productivity.

- Coolant system: For effective cooling during machining.

- Ease of maintenance: For reducing downtime and repair costs.

What types of cutter tools are best for bed-type milling?

The best cutter tools for bed-type milling machines include:

- Carbide tools: For high-speed cutting and longer tool life, particularly for hard metals.

- High-speed steel (HSS): Suitable for softer materials.

- Indexable inserts: For cost-effective and efficient cutting, especially in batch production.

Choosing the right tool depends on the material being machined and the specific operation.

How do you maintain a bed-type milling machine?

To maintain a bed-type milling machine:

- Clean the machine regularly: Remove chips, debris, and coolant buildup.

- Lubricate moving parts: Ensure smooth operation and prevent wear.

- Check alignment: Ensure the machine remains level and aligned to maintain accuracy.

- Inspect the spindle and bearings: Regularly check for wear or damage.

- Monitor coolant levels and filtration: Clean the coolant regularly to avoid contamination.

Proper maintenance increases the lifespan of the machine and ensures optimal performance.

Can bed-type milling machines be used for precision machining?

Yes, bed-type milling machines are highly suitable for precision machining due to their rigid structure, stability, and ability to maintain tight tolerances. They are commonly used in industries such as aerospace, automotive, and mold-making, where precision is critical for the final product.

What is the maximum weight a bed-type milling machine can handle?

The maximum weight a bed-type milling machine can handle varies depending on the model and manufacturer. Typically, bed-type mills are designed to handle heavy workpieces ranging from several hundred kilograms to several tons. Always check the machine’s specifications to determine its load capacity.

How does a bed-type milling machine compare to a planer-type milling machine?

Both bed-type milling machines and planer-type milling machines are designed for large workpieces, but they differ in structure and function:

- Bed-type milling machines have a stationary table, and the spindle moves along the bed in both vertical and horizontal directions.

- Planer-type mills have a moving table that can travel horizontally and vertically, offering greater flexibility for larger and more complex workpieces.

Bed-type mills are more rigid and ideal for precision, while planer-type mills offer more flexibility for larger, more diverse machining needs.

What are the benefits of using a CNC bed-type milling machine in high-volume production?

A CNC bed-type milling machine offers several benefits for high-volume production:

- Increased efficiency: Automated operations reduce cycle time.

- Consistency: CNC machines provide consistent quality, reducing the chances of human error.

- High precision: CNC controls allow for tight tolerances, crucial in high-volume production.

- Reduced labor costs: CNC machines require minimal manual intervention.

Are bed-type milling machines better for large or small parts?

Bed-type milling machines are typically better suited for large parts due to their size, rigidity, and ability to handle heavy workpieces. While they can handle small parts, they are most efficient for large, heavy, or complex components that require high precision.

What is the typical cost range for a bed-type milling machine?

The cost of a bed-type milling machine varies depending on features like size, power, and whether it's manual or CNC. Prices typically range from $10,000 for smaller, entry-level manual machines to $150,000 or more for high-end CNC models with advanced features.

How long does a bed-type milling machine last with regular maintenance?

With proper care and regular maintenance, a bed-type milling machine can last for several decades. The lifespan will depend on usage, but many machines can operate efficiently for 20 to 30 years with regular servicing and part replacements.

What is the difference between a bed-type milling machine and a gantry milling machine?

A gantry milling machine is similar to a bed-type mill but offers more flexibility, with the ability to move the cutting tool in multiple directions. It is often used for very large parts and offers more complex movements, while bed-type mills are more rigid and best suited for precision operations on medium to large-sized workpieces.

Are there any specific challenges when using a bed-type milling machine for heavy materials?

Machining heavy materials like titanium or hardened steel can present challenges such as:

- Tool wear: Harder materials can cause quicker tool wear, requiring more frequent tool changes.

- Heat generation: Heavy cutting can generate heat, which can affect both the material and the machine's performance. Effective cooling and high-quality tools are essential.

- Vibration: Large, heavy parts can cause vibrations that affect precision, so machine stability and proper setup are crucial.

How does the cutting speed of a bed-type milling machine affect productivity?

Faster cutting speeds generally lead to higher productivity, reducing cycle times and increasing throughput. However, higher cutting speeds can result in greater tool wear, so it's important to balance speed with precision and tool life. Optimal cutting speed depends on the material and the machine’s capabilities.

Can bed-type milling machines be used for both vertical and horizontal machining operations?

Yes, many bed-type milling machines are capable of both vertical and horizontal machining operations. The spindle on some machines can be adjusted to perform both types of operations, making them versatile for various applications. However, machines specifically designed for vertical or horizontal operations may offer better performance for those specific tasks.