To provide a comprehensive professional overview of industrial metal cutting solutions, helping fabrication experts choose the right machinery, optimize their cutting workflows and understand the market landscape for high-capacity bandsaw technology.

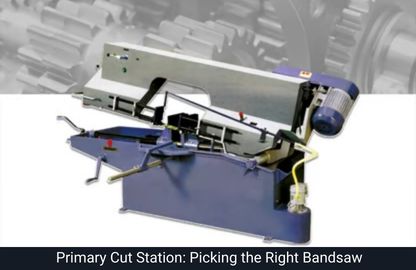

In the world of heavy-duty industrial fabrication, the precision and efficiency of the initial cut dictate the quality of the finished product. Whether a facility is processing massive structural beams or intricate tool steel components, the choice of a Metal Cutting Bandsaw Machine remains a cornerstone of the production line. As global manufacturing demands rise, the shift toward higher automation and specialized cutting geometries has transformed how shops evaluate their equipment. This guide explores the critical facets of selecting, operating and optimizing these essential tools to ensure long-term operational success.

Horizontal Bandsaw Machine Utility in High-Volume Production

The backbone of most structural steel shops is the Horizontal Bandsaw Machine. Its design, where the blade descends vertically or on a pivot through the workpiece, is engineered for stability and straightness when dealing with thick stock. In a heavy-duty environment, the primary advantage of a horizontal bandsaw lies in its ability to handle “gravity-fed” or hydraulic downward pressure, which ensures a consistent chip load across the entire width of the material. When fabricators move beyond manual operations, they often look toward a Fully automatic bandsaw to reduce labor costs and eliminate human error in repetitive cutting tasks. These machines allow for continuous feeding of bar stock, making them indispensable for high-throughput facilities that prioritize a streamlined workflow from raw material to the machining center.

Vertical Bandsaw Machine Versatility for Intricate Geometries

While horizontal units dominate the world of straight cutoff work, a Vertical Bandsaw Machine offers a level of flexibility that is unmatched in the fabrication shop. The stationary blade and movable table allow operators to guide the workpiece through complex curves, notches and contours. This makes the vertical bandsaw the preferred choice for tool and die makers or shops that perform custom prototyping. Beyond simple cutting, many of these machines are equipped with integrated grinding and welding stations. A Bandsaw Butt Welding Machine is often built into the frame of vertical units, allowing the operator to cut the blade, loop it through an internal hole in a workpiece and weld it back together for internal “blind” cuts. This capability transforms the Bandsaw from a simple cutoff tool into a multi-functional fabrication station.

250mm Capacity Bandsaw Machine Considerations for Mid-Range Fabrication

Choosing the right size of equipment is a balance between current needs and future growth. A 250mm capacity bandsaw machine is frequently cited as the “sweet spot” for medium-sized fabrication units. This size provides enough throat depth and clearance to handle the majority of standard pipes, tubes and square sections used in construction and frame building. When shops specify a 250mm diameter bandsaw machine, they are looking for a footprint that doesn’t overwhelm the shop floor while still providing the rigidity required for vibration-free cutting. Reliability in this category is paramount, as these machines often run for multiple shifts a day, acting as the primary entry point for all raw materials entering the production cycle.

300mm Capacity Bandsaw Machine Requirements for Heavy-Duty Industrial Tasks

When the scale of projects increases to include heavy-walled structural tubing or solid large-diameter rounds, the 300mm capacity bandsaw machine becomes the industry standard. The transition from a smaller unit to this capacity involves more than just a larger frame; it requires more powerful motors, wider blades and enhanced coolant systems to manage the heat generated during prolonged cuts. Using a 300mm capacity bandsaw machine allows a shop to take on larger industrial contracts, such as oil and gas infrastructure or heavy vehicle chassis manufacturing. The increased mass of these machines naturally dampens harmonics, leading to a cleaner surface finish and longer tool life, which significantly lowers the cost per cut over the life of the equipment.

Our Other Machine

Bandsaw Machine – Double Column Fully-Automatic PLC Control SeriesAngular Cutting Bandsaw Machine Precision for Structural Framing

In structural fabrication, the ability to cut accurate mitres is just as important as the ability to cut straight. An Angular cutting bandsaw machine is designed specifically to swing the saw head or the workpiece to precise degrees, allowing for the creation of frames, trusses and complex joints. Unlike standard machines that might require cumbersome jigs, a dedicated angular Metal Cutting Bandsaw Machine features a swiveling base with calibrated scales. This ensures that when two pieces of steel meet, the fit-up is tight, reducing the amount of gap-filling required during the welding process. This precision not only saves time in assembly but also improves the structural integrity of the final weldment.

Top Manufacturers of Bandsaw Machine and the Landscape of Quality

Navigating the market requires an understanding of who leads the industry in innovation and build quality. The Top manufacturers of bandsaw machine focus on integrating smart technology into their frames, such as load-sensing valves that automatically adjust the feed rate based on the resistance of the material. When researching a Fully automatic bandsaw machine price, it is vital to look beyond the initial capital expenditure and consider the availability of spare parts and the reputation of the manufacturer for after-sales support. Premium manufacturers often differentiate themselves through the use of high-grade cast iron components and precision-ground guide arms, which prevent blade “wandering” – a common issue in lower-tier machinery that leads to scrapped material and wasted time.

Bimetal Bandsaw Blade Manufacturers

The machine provides the power and the frame, but the blade does the work. Leading Bimetal bandsaw blade manufacturers have revolutionized the industry by bonding a high-speed steel edge to a flexible spring-steel backing. This combination allows the Bandsaw to withstand the immense heat and tension required to cut through hardened alloys without snapping. Selecting the correct tooth pitch and blade material is essential; even the most expensive Fully automatic bandsaw machine will perform poorly if paired with a low-quality blade. Understanding the synergy between the machine’s rigidity and the blade’s metallurgy is the secret to achieving high-speed cutting without sacrificing the accuracy of the finish.

Fully Automatic Bandsaw Machine Price and the ROI

Investing in automation is a significant decision for any business. While the Fully automatic bandsaw machine price may be higher upfront compared to semi-automatic or manual models, the long-term savings in man-hours and material optimization often justify the cost. A fully automated system can be programmed to cut different lengths from a single bar, with sensors detecting the end of the material to shut the machine down safely. This “lights-out” capability allows shops to run production over breaks or even between shifts, drastically increasing the total output of the facility. When calculating the return on investment, fabricators should consider the reduction in kerf loss and the precision of the cuts, which minimizes the need for secondary machining or grinding.

Email Us

Email Us

Optimization Strategies for Long-Term Bandsaw Performance

To keep a Metal Cutting Bandsaw Machine running at peak performance, a rigorous maintenance schedule is required. This involves more than just changing the coolant; it requires checking the alignment of the blade guides, ensuring the hydraulic tension is set correctly and inspecting the drive belts for wear. A well-maintained horizontal bandsaw or vertical bandsaw will provide decades of service. Furthermore, operators should be trained to recognize the signs of a dulling blade – such as increased noise or a change in the color of the chips – to prevent damage to the machine’s motor. By focusing on these small operational details, a fabrication shop can ensure that their cutting department remains a profit center rather than a bottleneck.

Our Other Machine

Bandsaw Machine – Swing Arm Portable SeriesConclusion

The selection of a Metal Cutting Bandsaw Machine is one of the most impactful decisions a fabrication manager can make. Whether the facility requires the high-speed throughput of a Fully automatic bandsaw or the intricate capabilities of a Vertical Bandsaw Machine, the goal remains the same: precision, efficiency and reliability. By understanding the differences between a 250mm dia bandsaw machine and a 300mm capacity bandsaw machine and by partnering with Top manufacturers of bandsaw machine, businesses can position themselves to handle the most demanding projects in the industry. Ultimately, the combination of a rigid machine, a high-quality product from reputable Bimetal bandsaw blade manufacturers and a commitment to maintenance will define the success of any heavy-duty fabrication operation.