Oman’s industrial sector has witnessed significant growth in recent years, fueled by the increasing demand for precision tools and machines. Industrial machinery such as Hydraulic Ironworkers, Tool & Cutter Grinding Machines, and Blade Sharpeners play a crucial role in enhancing productivity and efficiency in metalworking, woodworking, and manufacturing industries. This article highlights the key features, applications, and benefits of these powerful machines in Oman’s growing market.

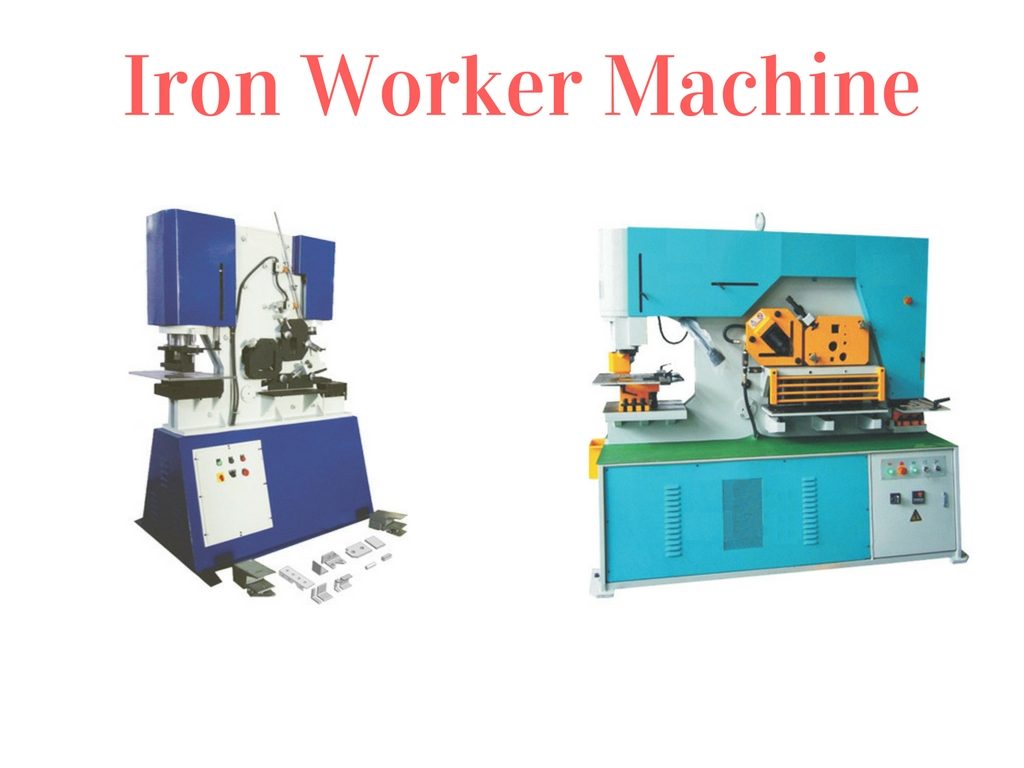

Hydraulic Ironworker: A Powerful Industrial Tool

A Hydraulic Ironworker is a multi-functional machine designed for cutting, punching, shearing, and bending metal. It combines versatility and power, making it ideal for metal fabrication processes.

Key Features and Benefits:

- Multi-Tasking Capabilities: Performs multiple functions like punching holes, shearing metal sheets, and bending plates.

- High Precision: Ensures clean and accurate cuts with minimal wastage.

- Time-Saving: Performs tasks that would otherwise require multiple machines.

- Durability: Built with robust materials for long-term usage.

Industries in Oman That Benefit:

- Metal fabrication workshops.

- Construction companies.

- Automotive and aerospace industries.

With its ability to handle complex metalwork processes, the Hydraulic Ironworker is a necessity for Oman’s booming manufacturing sector.

Universal Tool & Cutter Grinding Machine

The Universal Tool & Cutter Grinding Machine is an essential tool for sharpening and grinding cutting tools. This machine ensures tools are maintained to deliver optimum performance.

Features and Applications:

- Versatility: Suitable for grinding various tools like end mills, drills, and cutters.

- High Precision Grinding: Provides accurate and sharp edges, reducing tool replacement costs.

- Ease of Use: User-friendly interface for operators.

Importance in Oman’s Industries:

Oman’s manufacturing sector relies on precision tools to maintain high standards. The Universal Tool & Cutter Grinding Machine minimizes downtime and improves the productivity of tools used in industries like woodworking, metalworking, and machining.

Saw Blade Sharpener: Precision and Efficiency

The Saw Blade Sharpener is designed to maintain sharpness and precision in saw blades used across different industries.

Key Features and Benefits:

- Precision Sharpening: Restores blades to their original sharpness for clean and accurate cuts.

- Cost-Effective: Extends the lifespan of saw blades, reducing replacement costs.

- Automated Sharpening: Modern machines come with automated features for efficiency.

Applications in Oman:

Saw Blade Sharpeners are essential in industries that require continuous cutting operations, such as woodworking, furniture manufacturing, and construction. By ensuring blades remain sharp, these machines improve productivity and output quality.

Tool & Cutter Grinding Machine: An Industrial Necessity

Similar to the Universal Tool Grinder, the Tool & Cutter Grinding Machine ensures tools remain sharp and functional for various applications.

Key Differences and Applications:

- High Precision: Suitable for sharpening specialized tools and complex shapes.

- Flexibility: Ideal for metalworking, automotive, and construction industries.

- Durability: Built for heavy-duty industrial use.

Benefits for Oman’s Manufacturing Sector:

Oman’s manufacturers can increase productivity by ensuring cutting tools are consistently sharp and reliable. This machine reduces downtime, improves accuracy, and ensures cost savings.

Band Saw Blade Sharpener

The Band Saw Blade Sharpener is specifically designed for sharpening band saw blades used in cutting wood, metal, and other materials.

Top Features and Advantages:

- Automated Sharpening: Reduces manual effort and ensures consistency.

- Cost Efficiency: Prolongs the lifespan of expensive blades.

- High Precision: Delivers accurate sharpening for clean, smooth cuts.

Role in Oman’s Industries:

Industries like woodworking, metal fabrication, and furniture production benefit from Band Saw Blade Sharpeners. These machines ensure blades remain functional, reducing downtime and enhancing output quality.

Bandsaw Blade Sharpener: Ensuring Smooth Cutting

The Bandsaw Blade Sharpener is another variant that ensures bandsaw blades operate at peak efficiency.

Key Benefits:

- Extends blade lifespan.

- Improves cutting precision and reduces waste.

- Essential for industries requiring continuous cutting operations.

For Oman’s growing construction and woodworking industries, Bandsaw Blade Sharpeners play a key role in ensuring operational efficiency.

Iron Worker: A Versatile Industrial Solution

The Iron Worker is another industrial machine similar to Hydraulic Ironworkers, performing essential metalworking tasks like punching, bending, and cutting.

Applications and Importance in Oman:

With Oman’s infrastructure projects and growing construction demands, the Iron Worker remains a critical asset for metal fabrication and precision engineering tasks.

Chamfer: Enhancing Precision in Metalwork

Chamfering involves creating beveled edges on materials, improving precision and finish quality. Machines designed for chamfering ensure clean edges, which are crucial in manufacturing processes.

Applications in Oman:

- Automotive and aerospace industries.

- Construction and piping systems.

Conclusion

Oman’s industrial sector depends on advanced machinery to maintain productivity, precision, and efficiency. Machines like Hydraulic Ironworkers, Tool and Cutter Grinding Machines, and Blade Sharpeners play a significant role in enhancing manufacturing output. Investing in these machines ensures cost savings, reduced downtime, and consistent quality.