In the evolving landscape of small and medium-scale manufacturing, precision, efficiency and flexibility are paramount. One piece of equipment that increasingly meets these demands is the electric tapping machine. From pneumatic arm tapping machines to advanced touch screen tapping machines, electric models stand out for their adaptability and performance.

This article explores why electric tapping machines have become the preferred solution for manufacturers aiming to improve productivity and maintain high-quality threading operations. It highlights how innovation interfaces contribute to operational excellence.

Key Features of Electric Tapping Machines Beneficial for SMEs

Small and medium enterprises (SMEs) require machinery that offers both versatility and reliability without excessive operational complexity. Electric tapping machines satisfy these criteria through several core features:

Flexibility and Ease of Operation

Electric tapping machines often include ergonomic designs like flexible arms and intuitive touch screen controls that simplify operation. This flexibility allows operators to work on diverse workpieces and threading tasks with minimal setup time, ideal for SMEs with varied production needs.

High Precision and Consistency

The integration of servo motors in flexi arm electric tapping machines ensures consistent torque and speed control, producing accurate threads repeatedly. This reliability minimizes rework, improving overall manufacturing efficiency.

Energy Efficiency

Compared to models, electric tapping machines consume less power, reducing operational costs. This efficiency can be especially significant in small workshops where energy consumption directly impacts profitability.

Role of Touch Screen Technology in Modern Electric Tapping Machines

The incorporation of touch screen technology marks a significant evolution in usability and precision.

Benefits Include:

- User-Friendly Interface: Operators can easily program tapping parameters, reducing human error.

- Data Storage and Recall: Machines store multiple job profiles, enabling quick changeovers and consistent production.

- Diagnostic and Safety Features: Real-time monitoring through the interface helps prevent tool breakage and ensures safe operation.

For SMEs, these features translate into reduced training time and increased throughput.

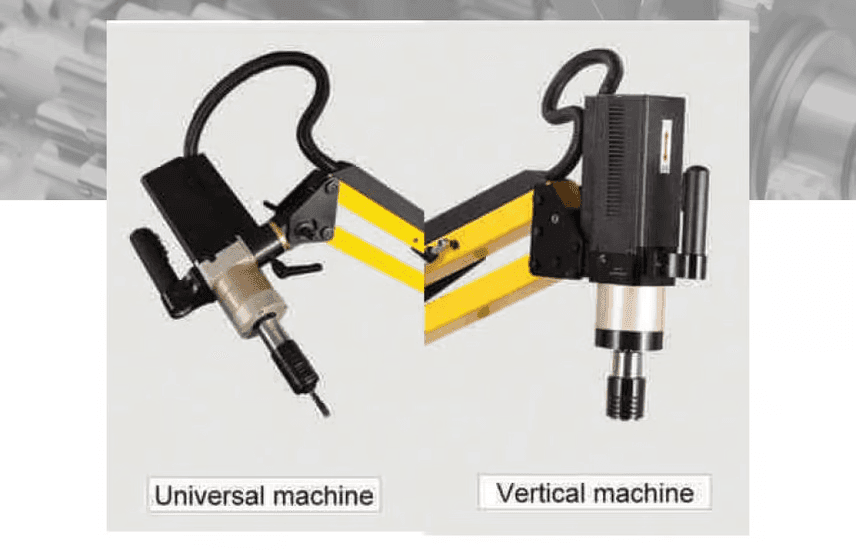

Universal Tapping Machines: Versatility for Diverse Manufacturing Needs

Universal tapping machines adapt to a wide range of threading requirements, from different sizes and materials to complex geometries. Electric models in this category offer:

- Adjustable Speeds: Catering to various material types.

- Flexible Tooling Options: Compatible with a broad range of taps.

- Robust Build: Suitable for frequent changeovers typical in small and medium-scale workshops.

This versatility makes them invaluable for manufacturers who produce small batches of varied parts.

Productivity Gains with Automatic Tapping Machines with Touch Screen

Automation is a game-changer in tapping operations. Automatic tapping machines with touch screen capability automate threading cycles, minimizing manual intervention.

Key productivity benefits include:

- Faster Cycle Times: Precise control and repeatability speed up production.

- Reduced Operator Fatigue: Automation handles repetitive tasks.

- Improved Quality Control: Consistent threading reduces rejects.

For SMEs, investing in such machines can enhance competitiveness by increasing output without compromising quality.

What Our Customers Say

“Hi kishan this side from ganesh industries, i have purchased a drill bit grinder machine months before, after using this machine i have achieved proper size of drill holes as well as low wear and tear of drill, ratio of drill break is significantly decreased and production increased due to less resharpening cycles, the machine i purchase is 13A and i am impressed with the speed and low maintenance of the machine,Thank you hasthbhai for serving us very well at company.”

Kishan Bhut On Google

Why Electric Tapping Machines are Suited for Small and Medium-Scale Manufacturing

The characteristics of small and medium-scale manufacturing environments align well with the strengths of electric tapping machines:

- Space Efficiency: Many electric tapping machines are compact, fitting smaller workshops.

- Cost-Effectiveness: Moderate initial investment balanced with low operational costs.

- Adaptability: Ability to handle varying materials and job complexities without extensive retooling.

These factors contribute to why electric tapping machines may offer the best return on investment for SMEs.

Maintenance and Durability Advantages of Electric Tapping Machines

Durability and ease of maintenance are critical for continuous manufacturing operations. Electric tapping machines often feature:

- Robust Construction: Designed to withstand heavy-duty tapping without excessive wear.

- Simplified Servicing: Fewer pneumatic components reduce maintenance complexity.

- Longer Tool Life: Controlled tapping speeds and torque prevent tap breakage.

This reliability minimizes downtime and repair costs, key considerations for small and medium enterprises.

Conclusion:

The growing preference in small and medium-scale manufacturing stems from their precision, flexibility and cost-efficiency. Whether deploying pneumatic arm tapping machines, SMEs benefit from improved productivity and consistent quality.

Universal tapping machine interfaces further enhance operational ease and throughput, making electric models the best choice for modern manufacturing challenges.

For small and medium enterprises aiming to optimize their threading processes, investing in electric tapping machines can lead to long-term gains in efficiency, product quality and profitability.