Metals and Metallurgical Concern in Industries

Metallurgical concern is more important when it comes to selection of machining components. If you are very particular about investing for long term and continuous production requirements, then selection of equipments which are designed with perfect metallurgical significance can provide you best results.

Materials Engineering and their Significance in Obtaining Consistent Results

Working with metals is one of the highly competitive industrial jobs. Though there may be wide range of apparatus available today, the point of achieving maximum percentage of accuracy and production can be reached only with the help of smooth functioning or performance of equipment. Successful materials engineering is more related to maintaining compatibility of metals and machining tools as this will help you to reach consistency in production targets.

Blade Provision-Why and what to look for?

If you are making commercial produce using steel, carbon, aluminium, etc, then it is the right time to check out blade provision. This is the main tool that plays multiple roles of cutting, sawing, etc. and it has to endure operations when fed with varieties of metals.

The Important Tooling Operations

If you are investing over sawing equipment, it would be fine to check its compatibility of performance when fed with carbon, stainless steel or nickel base steel, and with varieties of produce like pipes and tubes. A blade has to be durable and strong to work with mixed metal applications and to bring out this effect, you can verify the metallurgical details from the manufacturer.

Saw Device-An Ideal Choice of Apparatus for Complicated Works

An apparatus like bandsaw machine is one among the list of devices where metallurgical concern plays a prominent role, especially when it comes to blade provision and for dealing with multiple metals.

Blade Metallurgy in Bandsaw-Some Important Aspects to Consider

- Ensure the raw material from which the blade is made of. Cast iron may work out efficiently to work with different metals.

- Check the tooth tip formation, as it has to match tooling demands of your industry.

- Buying bimetal blades stays a suitable choice for handling pipes made of mild steel.

- The teeth size is more important when you are hunting for equipment that can work with stainless steel.

- Cutting edge made of abrasion resistive material can also stay very adoptive to deal with varieties of materials.

- If the sharp edge is made of minimized chipping, it is well and good to work with stainless steel.

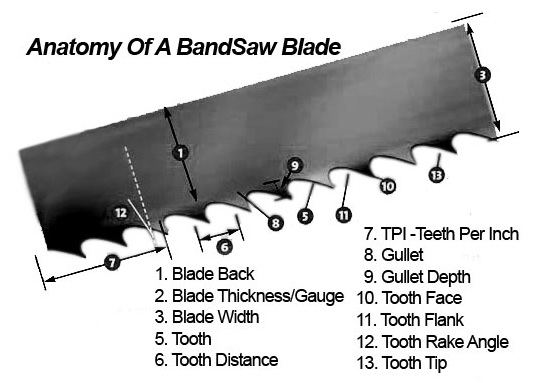

- Other important considerations include tooth rake angle, flant, tooth distance, thickness and width will also have to be equally looked out for.

How to select a perfect Saw focusing on Blade Capacity?

The most important point of determining which kind of bandsaw can work out well is to choose the kind of blade along with other kinds of settings like configuration of saw, speed, stack pattern, feed pressure, etc. These features will help you out to have cost effective cutting. Bhavya Machine Tools manufactures and supplies technically well equipped sawing device with the above specifications.

Conclusion

Cutting operations on metal components for long term usage has lot to depend on selection of tooling gadgets therefore, it would be much better to check for the metallurgical concerns to achieve maximum results.