Pipe bending machines are utilized to bend pipes and tubes to create curved formed sections. This machinery is useful for many applications, such as pipe sealing, pipe bending, pipe assembly, and pipe breaking. Tubular pipes are generally made of bent metal, like steel, or aluminium. A pipe bender is capable of working both inside and outside diameters. The bends often come with an inside diameter as well as an outside diameter and are designed to be pressed together using a machine that can achieve any required diameter.

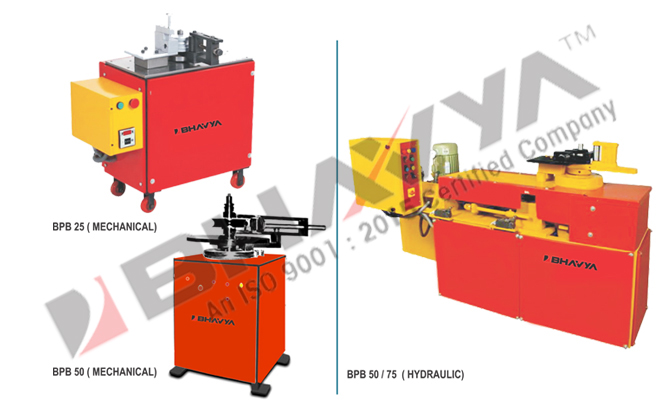

Main Equipment of Pipe Bending Machine

In the pipe bending machine, there is a series of tools that are utilized to do the work. The main equipment includes a pipe bending machine; a die head; a bending line; a clamping block; and an adjustable die. A pipe bender machine is a much more efficient method of forming pipes than conventional bending machines. It also offers several benefits over bender machines, including the ability to work at greater speeds, using less manual labour, using standard industrial parts, and saving on material costs. The following are additional details about the pipe bending machine operation.

Working Principle of Pipe Bending Machine

To start the work, the operator places the clamping block in the appropriate position on the pipe. Then, the machine’s control panel begins to function. By using the control panel, the operator activates the machine, which starts the ball-bearing rolling action. As soon as the belt moves, the pulley system then exerts pressure on the pipe bending machine, which forces it to move along the curved path. This constant pressure inside the pipe causes the thin wall to break, thus resulting in the formation of the curved sections.

Applications of Pipe Bending Machine

The most common application of pipe bending machines is for pipeline construction and repair. For this purpose, the machines are generally inserted into the mainline. Then, it makes a complete round arch of the pipe to obtain a cylindrical shape. This further provides for the creation of profiles that are complementary to the pipe’s external curve. In addition to this, it also creates profiles that are not parallel to the pipeline.

Another application of this machine is for the construction and repair of underground piping systems. The main advantage of using mechanical force is that it saves energy that would normally be required for the construction and repair of underground piping systems. Some of the common tasks where the application of this machine is used include drawing out of bends, or corrugated piping. Also, when the pipe is bent, the external diameter of the stock pipe is usually smaller than that of the inside diameter of the inner wall of the pipe.

Best Features of Pipe Bending Machine

The hydraulic pipe bending machine has several additional useful features that make it different from the traditional hand bender. For example, its release knob allows the user to manually loosen and tighten the rod that binds the output spool of the machine. The user can also increase or decrease the amount of compression as well as the amount of tension. Furthermore, it has a locking mechanism that prevents the spool of the machine from being inadvertently released.