Introduction

In today’s fast-paced manufacturing environment, precision and efficiency are critical for staying competitive. CNC press brake machines offer the perfect solution for precise bending and forming of various materials, particularly sheet metal.

These machines provide user-friendly and cost-effective solutions for diverse industries ranging from automotive to construction, aerospace, and beyond. This article explores the features, benefits, and global reach of CNC press brake machines, highlighting why they are essential for modern industrial applications.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) press brake is a machine used for bending metal sheets and plates into predetermined shapes. Unlike traditional press brakes, CNC press brakes are equipped with advanced controllers that enable precise and repeatable bending operations. These machines use high-powered hydraulic or electric drives to apply force to the metal sheet, bending it accurately according to programmed specifications.

CNC press brakes offer an innovative way to streamline bending operations, making them a popular choice for industries requiring precision. With the ability to program multiple bending angles and operations in one sequence, CNC press brakes significantly reduce manual intervention and increase production efficiency.

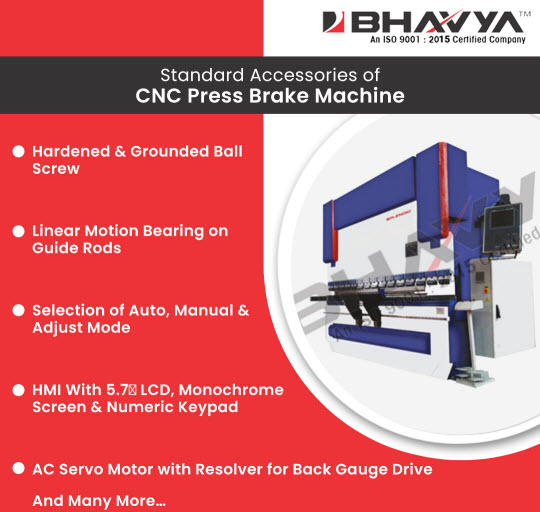

Key Features of CNC Press Brake Machines

- Precision Bending The standout feature of CNC press brake machines is their unparalleled precision. The integration of advanced CNC controllers ensures that every bend is executed to exact specifications, with tolerances measured down to the micron level. This makes them ideal for industries where accuracy is paramount, such as aerospace, automotive, and precision engineering.

- User-Friendly Interface Despite their advanced capabilities, CNC press brakes are incredibly user-friendly. The operator can easily input bending sequences, angles, and other parameters via a digital interface, often equipped with touchscreens. Some models even come with pre-installed bending programs that further simplify operation. This ease of use reduces the learning curve for operators and increases productivity.

- Customizable and Cost-Effective CNC press brake machines are designed to fit a wide range of bending requirements, making them highly customizable. Depending on the scale and complexity of operations, users can choose different versions of controllers to optimize their workflow. Furthermore, these machines are a cost-effective investment, as they reduce material waste and rework, resulting in long-term savings.

- Durability and Reliability CNC press brakes are engineered to last. Built with high-quality materials, these machines are designed to endure heavy-duty usage without compromising performance. Each section of the machine-from the hydraulic system to the controllers and tooling-is rigorously tested to ensure maximum reliability and durability in continuous operations.

- Advanced Technology Integration As a leading manufacturer, we incorporate cutting-edge technologies into our CNC press brake machines. From high-tech sensors that monitor force distribution to automated back gauge systems that enhance positioning accuracy, every aspect of the machine is optimized for precision and efficiency. These technologies ensure that the final result meets even the most stringent quality requirements.

Benefits of Using CNC Press Brake Machines

- Increased Productivity One of the key benefits of using CNC press brakes is the significant increase in productivity. These machines can perform multiple bends in one cycle, which drastically reduces production time. Additionally, the automation and programmability of CNC press brakes mean that once a sequence is set, the machine can run continuously with minimal supervision, leading to faster throughput and shorter lead times.

- Versatility Across Industries CNC press brakes are versatile machines capable of bending a variety of materials, including steel, aluminum, copper, and even high-strength alloys. This versatility makes them suitable for use in multiple industries, such as:

- Automotive: For the production of body panels, frames, and chassis components.

- Aerospace: For creating high-precision parts such as airframe components.

- Construction: For fabricating structural steel and architectural metal components.

- Furniture: For crafting metal frames and parts used in high-end furniture.

- Reduced Material Waste The precision offered by CNC press brake machines minimizes material wastage. Since each bend is executed with extreme accuracy, there is less chance of errors, reducing the need for rework and saving valuable materials. This is particularly important in industries dealing with expensive metals and materials, where every piece counts.

- Improved Safety CNC press brake machines come with built-in safety features, such as light curtains, pressure sensors, and emergency stop buttons. These features ensure that the machine can be safely operated, reducing the risk of accidents. By automating many of the bending processes, CNC press brakes also reduce manual handling, further enhancing workplace safety.

- Energy Efficiency CNC press brakes are designed to be energy efficient, especially models equipped with electric drives. Compared to older hydraulic models, electric CNC press brakes consume less power, helping manufacturers reduce their carbon footprint while lowering operational costs.

Global Reach and Expertise

As a market leader in the production of CNC press brake machines, we take pride in offering a comprehensive range of products tailored to meet the precise needs of various industrial applications. Our machines are used in industries worldwide, including in countries like India, Kuwait, Bahrain, Iraq, Qatar, Oman, United Arab Emirates, Saudi Arabia, Dubai, and Yemen.

We specialize in engineering perfection, dependability, and accuracy. Our skilled production team ensures that every component-from raw materials to the final assembled machine-meets the highest standards of quality. We source premium-grade materials and components to build machines that are not only durable but also highly productive.

Commitment to Quality and Customization

As a manufacturer, we understand that every client has unique requirements. That’s why we offer CNC press brake machines that can be fully customized. Whether it’s selecting advanced controllers, tooling options, or even specialized accessories, we provide tailored solutions to meet the specific demands of our clients. This level of customization ensures that businesses receive machines that align perfectly with their production goals, enhancing both efficiency and output quality.

Additionally, our team of experts works closely with clients to ensure that they receive optimal solutions that fit their budget and operational needs. From consulting on the best machine specifications to after-sales support and training, we are committed to providing a seamless and satisfying experience for our customers.

Customer Satisfaction and After-Sales Support

At Bhavya Machine Tools, we believe in long-term partnerships. Our commitment to customer satisfaction doesn’t end with the sale. We offer comprehensive after-sales support, including maintenance services, technical assistance, and operator training to ensure that our clients get the most out of their CNC press brake machines.

Our experienced team is always available to provide guidance on machine operation, troubleshooting, and optimization, ensuring that our clients achieve consistent and flawless results from their machines.

Conclusion

CNC press brake machines represent the future of precision bending in modern manufacturing. With their ability to deliver accurate, consistent, and high-quality results, these machines are indispensable for industries that rely on sheet metal fabrication. Bhavya Machine Tools stands at the forefront of CNC press brake manufacturing, offering cutting-edge technology, customizable solutions, and world-class support to clients across the globe.

Whether you’re in the automotive, aerospace, construction, or any other industry requiring precise bending, investing in a CNC press brake machine is a step toward greater efficiency, cost-effectiveness, and operational success.