South Africa’s industrial landscape is a dynamic mix of mining, manufacturing and metal fabrication. As the country advances toward more efficient and precision-driven processes, the importance of specialized equipment, such as the hacksaw machine, cannot be understated. Hacksaw machines, whether mechanical, hydraulic or semi-hydraulic, play a critical role in optimizing metal fabrication workflows by offering speed, accuracy and reliability.

This article delves into the significance of hacksaw machines in South Africa’s metal fabrication industry, their types and how they are enhancing efficiency in this critical sector.

What is Hacksaw Machine?

Hacksaw machines are cutting tools specifically designed to cut through various types of metals, including steel, aluminium and alloys. Unlike traditional hand saws, hacksaw machines operate automatically or semi-automatically, drastically improving productivity in industrial settings.

The primary function of a hacksaw machine is to achieve precise cuts in a shorter time frame, making it a vital tool for businesses involved in metalworking. These machines are known for their simplicity, versatility and adaptability to different cutting requirements.

Types of Hacksaw Machines

The metal fabrication industry in South Africa benefits from several types of hacksaw machines, each designed to cater to specific operational needs:

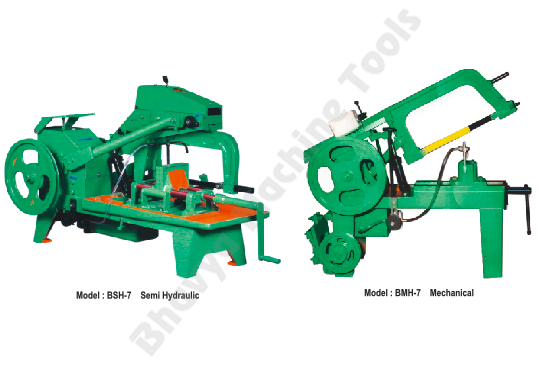

Mechanical Hacksaw Machine

A mechanical hacksaw machine is a basic and cost-effective solution for cutting metal. It operates using a motor-driven mechanism, which moves the blade in a reciprocating motion to achieve the desired cut.

- Advantages: Simple to use, affordable and reliable for smaller-scale operations.

- Applications: Commonly used in workshops for cutting medium-thickness materials.

Hydraulic Hacksaw Machine

A hydraulic hacksaw machine leverages hydraulic power to control the blade’s movement, offering precise and smooth cuts. The hydraulic mechanism ensures uniform pressure, reducing the risk of errors or inconsistencies.

- Advantages: Superior precision, reduced operator fatigue and suitable for heavy-duty applications.

- Applications: Ideal for cutting hard metals and large-scale operations in South Africa’s mining and manufacturing sectors.

Semi-Hydraulic Hacksaw Machine

The semi-hydraulic hacksaw machine combines features of both mechanical and hydraulic systems. It offers a balance of affordability and functionality, making it a popular choice for mid-sized operations.

- Advantages: Cost-effective while providing reasonable precision and efficiency.

- Applications: Used in fabrication shops and small industries.

Hacksaw Machines and Its Role in South Africa’s Metal Fabrication Sector

Improving Cutting Efficiency

In the fast-paced world of metal fabrication, time is money. Hacksaw machines, particularly hydraulic hacksaw machines, offer unmatched speed and accuracy in cutting metals. This efficiency allows South African manufacturers to meet tight deadlines without compromising quality.

Reducing Material Wastage

Precision cutting reduces material wastage, a critical factor in industries dealing with expensive metals such as titanium or stainless steel. Hacksaw machines ensure clean and precise cuts, helping South African businesses optimize their resources.

Versatility Across Applications

From cutting structural beams for construction to shaping components for automotive manufacturing, hacksaw machines are versatile enough to handle a wide range of applications. This adaptability is particularly beneficial in South Africa, where the metal fabrication industry supports multiple sectors.

Enhancing Workplace Safety

Traditional cutting tools pose significant safety risks to operators. Hacksaw machines minimize manual intervention, reducing the likelihood of accidents. Hydraulic hacksaw machines, with their automated operations, further ensure safe and consistent performance.

Boosting Industrial Productivity

By enabling faster, more accurate and reliable cuts, hacksaw machines contribute to overall productivity in metal fabrication. This is especially crucial for South African businesses competing in global markets where efficiency and quality are paramount.

Key Features of High-Performance Hacksaw Machines in South Africa’s Metal Fabrication Sector

Adjustable Blade Speeds

Most modern hacksaw machines offer adjustable blade speeds, allowing operators to tailor the cutting process to different materials and thicknesses.

Durable Construction

Designed to handle rigorous industrial applications, these machines are made from high-grade materials to ensure longevity and minimal downtime.

Coolant Systems

Integrated coolant systems in hydraulic and semi-hydraulic hacksaw machines help maintain optimal blade temperatures, reducing wear and ensuring smoother cuts.

Automatic Feed Systems

Automatic feed mechanisms streamline the cutting process, eliminating the need for constant manual adjustments and supervision.

Factors to Consider When Choosing a Hacksaw Machine

Selecting the right hacksaw machine is crucial for maximizing efficiency and achieving high-quality results. Here’s what South African businesses should consider:

Material Type and Thickness

The type of materials being cut-whether lightweight aluminium or heavy-duty steel-determines the power and blade strength required. Hydraulic hacksaw machines are ideal for harder, thicker metals.

Volume of Operations

For high-volume operations, a hydraulic or semi-hydraulic hacksaw machine offers the speed and consistency needed to meet demand.

Precision Requirements

Industries requiring tight tolerances, such as aerospace or automotive, benefit from machines with superior precision features like hydraulic pressure control.

Machine Size and Workspace

Consider the available workspace and the size of the materials being cut. Compact machines may be suitable for smaller workshops, while larger machines are better for heavy-duty industrial environments.

The Impact of Hacksaw Machines on South Africa’s Economy

South Africa’s metal fabrication sector is a key contributor to the nation’s economy, supporting industries such as mining, construction, automotive manufacturing and renewable energy. Hacksaw machines play an instrumental role in driving efficiency and innovation in this sector.

Supporting Infrastructure Development

As South Africa continues to expand its infrastructure, hacksaw machines provide the tools necessary for shaping structural components like beams, pipes and sheets.

Advancing Automotive and Aerospace Manufacturing

The precision and efficiency offered by hacksaw machines are vital for producing high-quality parts for automotive and aerospace applications, ensuring South Africa remains competitive in these global industries.

Fostering Small and Medium Enterprises

Affordable and versatile hacksaw machines enable in South Africa to enhance their productivity and compete with larger players in the market.

Maintenance Tips for Hacksaw Machines

Proper maintenance ensures the longevity and optimal performance of hacksaw machines. Here are some essential tips:

- Regular Lubrication: Ensure all moving parts are adequately lubricated to reduce friction and wear.

- Blade Inspection: Check the blade for signs of wear or damage and replace it promptly to maintain cutting efficiency.

- Cleanliness: Remove metal shavings and debris after each use to prevent clogging and ensure smooth operation.

- Hydraulic System Checks: For hydraulic hacksaw machines, regularly inspect the hydraulic fluid levels and address any leaks.

The Future of Hacksaw Machines in South Africa

As South Africa embraces advanced manufacturing technologies, the role of hacksaw machines is set to evolve. With innovations in automation and digital integration, future machines are likely to feature enhanced precision, reduced energy consumption and improved user interfaces.

Moreover, the demand for sustainable practices will drive the development of eco-friendly hacksaw machines, aligning with global trends toward greener manufacturing solutions.

Conclusion

In conclusion, hacksaw machines are indispensable tools in South Africa’s metal fabrication sector. By enhancing efficiency, precision and safety, these machines enable businesses to meet the challenges of modern manufacturing while contributing to the country’s economic growth. Whether mechanical, hydraulic or semi-hydraulic, the right hacksaw machine can make all the difference in achieving operational excellence.