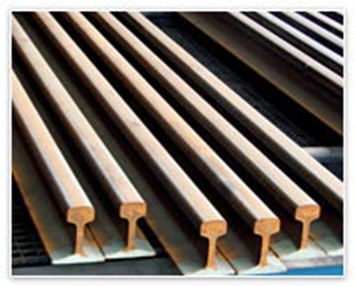

High Tensile Materials for Making Rail Components

Transporting vehicle needs excellent strength to bear load and support durability of usage. Cast or wrought iron are the most important raw ingredients considered for making cross sectional shapes of railway rail. These have to be set perpendicular to each other, therefore, symmetrical construction is mandatory. These are subject to extreme stresses and should be made from excellent quality of stuff to remain strong for several decades. There were different forms of tracks produced since earlier times like flanged rail with L cross section, baulk for light weight usage, Vignoles, double-headed, flanged and many more forms.

Difficulties in Shaping

Shaping or deforming sheets or blocks of tensile ingredients had been challenging as majority of work was done with manual support. Apart from that precision was also a matter of complication and reworking was also common until accuracy was reached. In most manufacturing processes where metal elements were regarded as basic ingredient, machining process remains top most requirements. Sheet metal equipment has replaced several contemplations regarding deforming needs. Profile making and bulk manufacture of gadgets made by using heavy duty basic elements have also become much comfortable with the above range of devices. Fabrication of rail profile is one among the kinds of jobs done easily with modern workshop tools.

Sheet Metal Device for Complete construction Support

This is considered as an exact device to achieve satisfactory cut and get sharp corners. The primary application of this instrument had been for cutting patterns over variety of textures like marble, wood, etc. However, later on its usage was felt to be appropriate for scratching stencils and for heavy duty jobs as well. Milling device is also employed in fabrication of rails. In addition to that, innovative machines like roll threading instrument and selection of corrosion resistant tensile material also remain important attributes for creating increased quantity of products at comparatively short time period.

Rapid Manufacture Support

When compared to traditional methodology of bulk production, this device provides scope for dimensional accuracy during multiple levels of production. Application of sophisticated assortment of machinery like CNC embedded instruments also makes production effective through easy operation. Diverse appearances of tracks can also be produced in accordance to purpose of usage. For example, light weight push trolleys appear like rails but they are meant for lifting wagons and heavy objects yet, these are durable, resistant to corrosion and strong in resisting abrasion also.

How Manufacturers Compete in Quality Management?

When it comes to quality assurance, producers will always look for higher grade ingredients because the produce needs to meet standard array of applications. The object also has to bear intense load capacities. Hence, based on the respective requirement such as rails in cement work, irrigation projects or sugar mills the dimensions change.

Conclusion

Heavy metal machining jobs are of various kinds, among them creation of profile rails for different sources vary between industries. However, with the shore up of profound duty apparatus creation process takes place in terms of fast, reliable and industry friendly performance.