Why A Workshop Is Necessary for Metal Working?

Why A Workshop Is Necessary for Metal Working?

The metal work will comprise of light metal applications such as jewelry to heavy duty applications such as automotive garage or building bridges. Metal work is an energy intensive activity that produces a lot of noise, dangerous debris in form of metal off-cuts, and excess fumes. In order to contain the dangerous residue and ensure that the working environment is safe and sound to the environment as well as human health, it is important to set up a proper metal workshop. A poorly laid out workshop or using the wrong kind of machine tools will more often than not create an unfriendly working environment that will be more prone to accidents.

What Influences the Design of a Metal Workshop?

Prior to constructing a metal workshop, it is necessary to carry out a detailed research in order to come up with the most feasible workshop. The type and size of the workshop will be influenced by the following:

• Availability of Space: large space makes it possible to create a large workshop that will house many apparatus while a limited space will only be sufficient for small devices.

• Type of Metal work: Heavy duty applications or activities taking place frequently require a large workshop while a smaller workshop will suit applications carried out rarely.

• Type of Machines: Large milling, bandsaw or any other tools require a commercial grade large sized workshop. A milling equipment for light metal work such as jewelry can be used in a small workshop.

• Legal Requirements: The location of the metal workshop will be influenced by the legislation as well as council bylaws. It is usually not allowed to set up an industrial workshop in a residential area. The local authorities will also authorize the setting up of a workshop based on social and environmental factors such as noise pollution.

• Power supply: A Standard sheet metal equipment, CNC lathes, press brake or power press will run on 110-240 volts (single phase) which is the domestic power supply. However, large bandsaw, sheet metal, power press as well as press brake equipment will require industrial power supply which comes in 3 phase with voltages of about 414 volts (AC).

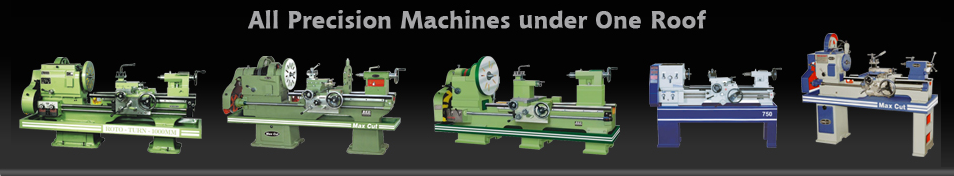

Types of Machines Used in A workshop

Machines used in a workshop for metal working come in various designs. The tools will include sheet metal, milling , press brake, bandsaw, power press and CNC lathes. High quality equipments will assure the user of top notch work, but it is important to regularly service and maintain the intruments as per the manufacturer’s recommendations. Failure to do so will shorten the life span of the machine. It is also beneficial to use genuine spare parts as well as a reputable service firm during repairs. Click Here to get more information on Workshop for Metal Jobs.

Conclusion

Coming up with a good workshop will entail a number of processes hence should not be viewed as a one-off activity. Periodic adjustments will be necessary to improve the service delivery. The ideal workshop needs to be cost effective providing reliable service at all times.