Objective:

This article explores key performance, quality and process optimization strategies for Pipe and Profile Bending Machines. It covers essential aspects such as improving bending accuracy, reducing material waste and ensuring proper maintenance. Additionally, it provides insights into the differences between various types of bending machines, from manual to NC-controlled systems and offers practical advice on selecting the right equipment for production needs.

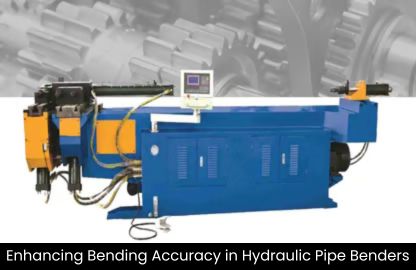

How to Improve Bending Accuracy in Hydraulic Pipe Bending Machines?

Improving bending accuracy in pipe bending machines is essential for ensuring high-quality results in production. One of the most effective methods to enhance precision is the use of high-quality tooling and ensuring proper calibration of the machine’s components. For Heavy-Pipe Bending Machines, ensuring the proper alignment of the pipe during the bending process is crucial for preventing distortion and achieving accurate bends. Additionally, regular maintenance and the use of Automatic CNC Pipe & Bar Cutting Machines can help reduce human error by automating the bending process, thus increasing overall accuracy. Monitoring hydraulic pressure and ensuring that the machine’s hydraulic fluid is in good condition are also important steps in maintaining consistent performance.

Reducing Material Waste in Tube and Profile Bending Operations

Reducing material waste is a critical aspect of optimizing the efficiency of Profile Bending Machines. One way to minimize waste is by using advanced software to pre-program bending operations, ensuring the most efficient use of material. Pipe Bending Machines should also be properly calibrated to reduce the amount of scrap material created during the bending process. Additionally, using advanced machines like the Pipe Bending Machines that offer precise control over bend angles and lengths allows manufacturers to get the most out of each tube or profile. Another key factor is optimizing the material’s cutting process with a Pipe Cutting Machine, ensuring that pieces are cut to the exact dimensions before being bent, minimizing excess material and maximizing production efficiency.

Importance of End Grinding Before Welding and Assembly

End grinding plays a crucial role in ensuring that pipes or profiles are properly prepared for welding and assembly. For both Pipe/Profile Bending Machines, grinding the ends of the pipe or profile smoothens any rough edges or burrs that could interfere with the welding process. Without proper grinding, these imperfections can lead to weak welds or poor fit during assembly. Hydraulic Pipe Bending Machines are often equipped with integrated grinding features or they can be paired with standalone Pipe Cutting Machines for the finishing process. This ensures that the material is in optimal condition for the next phase of production, which helps to improve both the strength and quality of the final welded assembly.

What Our Customers Say

“Recently we purchase tapping machine from bhavya machine tools and the performance of this machine is truly exceptional.”

Gulamrasul Panara On Google

Common Bending Defects and How to Avoid Them

Bending defects such as wrinkling, cracking and springback are common challenges in the bending process. For Hydraulic Bending Machines, these defects often occur due to incorrect machine settings, improper material selection or worn-out tooling. To avoid such issues, it’s important to ensure that the Profile Bending Machine is set up correctly, with the proper die radius and pressure settings. Operators should also select the appropriate pipe material that can handle the stresses of bending without cracking or distorting. Regular maintenance of the machine’s components, such as dies and rollers, is essential for minimizing defects. Additionally, using an Automatic CNC Pipe & Bar Cutting Machine for pre-cutting and preparing material before bending can ensure a cleaner and more accurate final product.

Choosing the Right Machine Capacity and Die Radius for Your Production Needs

Selecting the right machine capacity and die radius is a fundamental part of optimizing production in pipe and profile bending operations. Bending Machines are available in various capacities and selecting the appropriate one depends on the pipe diameter, material type and required bending angles. For larger, more robust materials, a Heavy Pipe Bending Machine with a higher capacity is necessary to ensure the material is bent without excessive strain. Additionally, selecting the right die radius ensures that the material is bent without excessive elongation or deformation. A die that is too small may cause the material to stretch, while a die that is too large can result in a less precise bend. Understanding your production needs and matching them with the capabilities of the bending machine is crucial for maximizing efficiency and quality.

Comparative Analysis: Manual vs Semi-Automatic vs NC Controlled Pipe Bending Machines

When considering Pipe Bending Machines, manufacturers must decide between manual, semi-automatic or NC-controlled (Numerical Control) systems. Manual Pipe Bending Machines require the most operator input, offering flexibility but often sacrificing precision and speed. Semi-Automatic Pipe Bending Machines offer a balance of flexibility and automation, allowing for quicker setups and consistent results with some manual intervention. On the other hand, NC Controlled Pipe Bending Machines, are the most advanced, providing highly precise and repeatable bending operations with minimal human involvement. For businesses looking to improve both speed and accuracy, Pipe Bending Machines equipped with NC or CNC controls are ideal, particularly for high-volume production that requires complex bends with tight tolerances.

Maintenance Checklist for Long Life of RBM and NCB Series Machines

Proper maintenance is essential to extend the lifespan and performance of RBM (Roll Bending Machine) and NCB (Numerical Control Bending Machine) series machines. Regular checks should be conducted on the hydraulic systems, ensuring that the fluid levels are optimal and the components are free from contamination. The machine’s electrical components should also be inspected to prevent malfunctions and the mechanical parts, including dies, rollers and shafts, should be lubricated and checked for wear. Additionally, the alignment of the machine should be periodically verified to prevent bending inaccuracies. A Pipe Bending Machine maintenance schedule should include regular cleaning of the machine’s parts and replacing any worn-out or damaged components to ensure continued high performance and minimal downtime. Scheduled servicing by trained technicians is recommended for machines such as Heavy Pipe Bending Machines, which require more robust care.

Conclusion:

Optimizing the performance, quality and efficiency of Pipe/Profile Bending Machines requires a combination of the right equipment, proper machine settings and diligent maintenance practices. Whether using Mechanical Pipe Bending Machines for simpler operations or investing in advanced Hydraulic Pipe Bending Machines for complex and high-volume production, understanding the technical aspects of each machine type is crucial for achieving accurate results. By focusing on key areas such as bending accuracy, waste reduction and machine maintenance, manufacturers can ensure smooth and cost-effective bending operations, resulting in higher quality products and reduced production costs.