When choosing a sheet metal bending machine, it is important to choose the one that can handle the materials you plan to bend. Each type has specific requirements for the materials that can be bent. The inner radius of the bending machine should be the same as the thickness of the material. If the flanges are shorter or longer, the material will be more difficult to bend. Likewise, the thickness of the material will affect the tonnage. The recommended specifications are listed below.

How to Buy Sheet Metal Bending Machine?

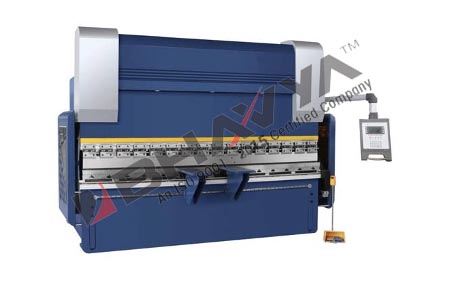

When purchasing a sheet metal bending machine, be sure to select one that is specifically designed for the job. A simple sheet bender may not be enough. More advanced bending machines are equipped with complex systems to produce more complicated shapes. The larger the rotary center, the longer the arc, and the more complex the bend. Bhavya machines are designed to handle these challenges and more. However, be aware of the following safety guidelines when purchasing a sheet metal forming machine.

Why Choosing Right Sheet Metal Bending Machine is Important?

Choosing the right machine is critical for the success of your project. The right angle and alignment of the dents in the sheet are crucial in making the parts look good. If the bending machine is not designed with this in mind, the sheets can get damaged or cause injury. The material’s strength will determine the type of bending process it can handle. Different metals have different load capacity and compressive strength is always superior to tensile strength. A better way to choose the right bending procedure for the material is to use an adjustable sizing tool. This tool will allow you to adjust the angle of your bend. This is a crucial consideration when you want to produce a high-quality product.

Features of Sheet Metal Bending Machine

The arc of the sheet metal needs to follow the contour of the bending die. The pressure die will help the material follow the desired contour. A wiper die will prevent the material from creating wrinkles or inner radii. The swivel bending machine should be able to accommodate these variables. The best one for your project will make your life easier and make your business profitable. When you have a quality sheet metal bending machine, you can be sure of high quality products.

In Conclusion

A sheet metal bending machine is used to make a variety of shapes. It can be used to fabricate a variety of shapes. The arc is too large for the bending machine. The pressure on the curved plate should be evenly distributed to avoid the center hole from being damaged. Aside from this, a sheet metal bender can also help you make prototypes for different uses. A good bending machine can make a design that will meet all your needs.