A Spot Welding Machine is used to permanently weld two pieces of metal together. The electrodes remain on the metal spots after the weld is finished and the controller is turned off. The welding process completes the fabrication of the metal sheet. The weld is a permanent one, which is why it is essential to use a high quality machine. Here are some of the features that you should look for in a spot welder.

Properties of Spot Welding Machine

The Spot Welding Machine is also known as an MIG welder. It has a very compact design and an easy-carry handle. The Milwaukee M18 spot welder is made of high-quality materials and is durable. It has closed-loop feedback control, a stable output voltage, and is energy-efficient. Its compact design is a great advantage for small spaces.

Operations of Spot Welding Machine

A Spot Welding Machine has a simple operation. This machine has two electrodes and a welding gun that propels the gun along a seam. It does not require pulsation for materials less than 0.8 mm thick, but pulsation is needed for thicker materials. The projection welding machine is a press that replaces the tipped electrodes with flat platers. It is commonly used for different components.

Advantages of Spot Welding Machine

Unlike the MIG welding machine, a Spot Welding Machine allows you to spot-weld a small part of a larger workpiece. You can weld a piece of metal with a smaller spot than a larger spot. The main advantage of using a Spot Welding Machine is that you can save a lot of time and effort. The electrodes are easy to insert into a piece of metal.

A Spot Welding Machine uses a small current to spot-weld a piece of metal. Unlike other types of welding machines, a Spot Welding Machine produces a small amount of heat, but the power that is applied can produce a large amount of heat. It is important to choose a weld welder with the appropriate specifications to ensure the best results.

Components of Spot Welding Machine

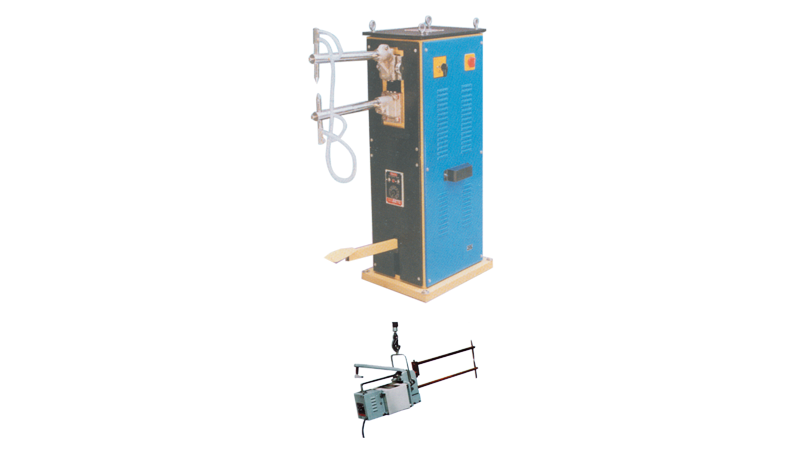

The Spot Welding machine is mainly composed of a fixed electrode and a movable electrode. The movable electrode contacts the weldment and conducts the heat welding treatment. In addition to the weldment, the Spot Welding machine also has a control system and a power source. A power source provides a constant flow of electricity. During the weld, a solid state relay controls the working status of the actuator.

The Bottom Line

An efficient spot welder should come with dual-pulse modes. A dual-pulse mode means that it uses two different electrodes. The electrodes should have the same electrical resistance. The second mode is a portable spot welder that has two shaped electrodes. These machines are usually portable and have a flexible cord. A welding machine with a flexible cord will enable you to weld metal sheets with a variety of thicknesses.