If you are in the market for a new shearing machine, you might want to take a look at the different types of machines available. These include block cutting machines, straight knife shearing machines, hand operated shearing machines, and more.

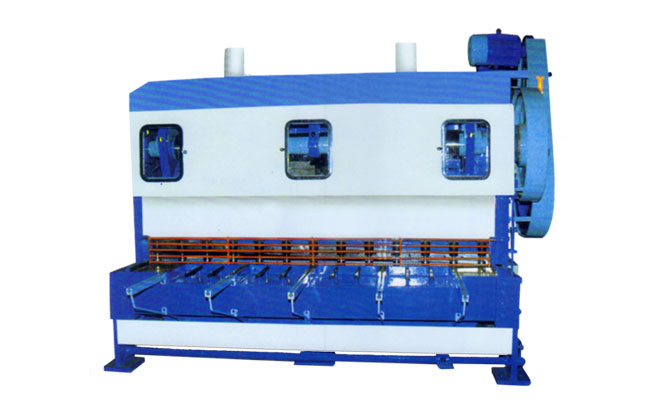

Straight Knife Shearing Machine

The straight knife shearing machine is a versatile cutting machine for cutting fabrics and components of different sizes and shapes. It uses a stationary lower knife and a movable upper one.

This type of cutting machine is ideal for use in a small-scale production unit. It is also suited for cutting fabrics that are dense and thick. It has the potential to cut a wide variety of materials and is easy to operate. It can be used to cut all kinds of fabric, including woven fabrics and knit fabrics.

It has a high cutting speed, ranging from 3000 to 4000 r.p.m. It also features a variable speed mechanism. This allows the operator to adjust the speed of the blades.

The cutting machine can be moved on wheels to make it easier to move and install it. It also has an auto lubricating system. It is accurate, noise free and quick.

A shaft mounted speed reduction unit helps reduce bowing and twist. It also offers instantaneous engagement. It is a much different driving method than that of the traditional mechanical shearer.

It features a self-detector to tell the operator if the machine is operating correctly. It also has a touch panel with digital display. It can be adjusted for cutting height and speed.

The straight knife is probably the most popular type of cutting machine. It is inexpensive, easy to use and portable. It is the most popular type of cutting device in the garment cutting industry. It is also the most effective in cutting garments in bulk. It can be used to cut a variety of materials and is the most efficient when it comes to making curvilinear cuts.

Block Cutting Machines

A block cutting machine is a device used to cut wood, metal or planks. These machines can be useful in many construction sectors. Usually, the upper and lower shear blades are made of high standard steel. These machines also have a digital display device on the upper shear blade.

These machines can be operated by skilled workers. They have many advantages, such as energy efficient operation, higher productivity and no need of cables or set-up. They can be a perfect solution for small to large jobs.

In addition, these block cutting machines have a wide variety of models, which make them useful in various places. They are also suitable for different industries, such as construction, automotive and aviation.

It is important to know how to operate the block cutting machine properly before starting the process. Before use, it is recommended that the workpiece be stopped and the anchor bolt be loosened. Then, the retaining plate should be lowered, and the fingers should be prevented from entering the mouth of the blade.

Once the shearing workpiece has been pressed to the plate, the holder on the lower shear blade must be locked. Before adjusting the shearing workpiece, it is recommended that the clamping mechanism, brake, and clutch are adjusted.

Besides, the hydraulic system of the shearing machine should be checked. If there are leakages or damage, it should be repaired or replaced. It should be lubricated daily. Moreover, it should be wiped clean before leaving the worksite.

If the shearing blade becomes dull or cracked, it is advisable to replace it. It is important to check the oil in the shearing machine and its quantity. It is also recommended that the blade is trimmed and the gap between the blades is inspected.

Hand Operated Shearing Machine

The hand operated shearing machine is a simple, efficient and cheap way to rough cut sheets of metal. There are several types of shearing machines available in the market. You can choose from table top, bench mounted, hydraulic or a combination of the two. There are numerous manufacturers of shearing machines in the UAE. The best ones are able to produce top-notch products at competitive rates.

The shearing machine can be used for all kinds of shearing, from thin sheet metal to thick alloys. The machine is also able to shave off the hefty price of the material with ease. The most important part of the process is that it does not leave any blemishes on the material, even if the material is a metallic alloy.

Another shearing machine related feat is the use of an illuminated cutting area for a clear view of the blades. The shearing machine is able to do the above thanks to the use of a special powder coating. Similarly, the most efficient one can be found in the UAE.

Other shearing devices include a rolling key clutch made of steel and spring operated brakes that work according to the set timing. In the end, the shearing machine may prove to be a mini project for a mechanical student.

The hand operated shearing machine is an effective and efficient tool that has a wide range of applications. The industry is abuzz with the latest innovations in shearing technology. These machines can be found in various forms and shapes to suit the needs of all industrial users.

Fracture in Shearing Machines

Shearing machines in Dubai are used to process metals. The shear pin structure may contact lugs during the fracture process, causing the shear pin to break into pieces. The strength of the shear pin structure is dependent on its maximum and minimum inner diameters. The internal shape of the shear pin is also affected by these parameters. Various types of shearing machines are available for different applications.

A shear pin with a maximum inner diameter of 26 mm dissipates 1605 kN of energy. This is comparable to the energy dissipated by a shear pin with an internal diameter of 24 mm. However, the failure load is significantly lower than that of a shear pin with an internal diameter less than 24 mm.

In order to improve the shear fracture performance, a new shear pin configuration was designed. The inner diameter of the new shear pin was decreased. Its structure was simulated by a finite element model. This simulation was then validated against an analytical solution. The results indicate that the numerical model is a reasonable approximation to the analytical solution.

The numerical model was able to simulate the crack propagation and the structural deformations of shear pins. It was also able to show that the impact velocity had a small influence on the failure mode. The simulated aperture profile was also consistent with the analytical solution. The simulation showed that the fractured granular face of the metal coincides with the intersection planes of the maximum shear stress. This means that the shearing process occurs at a sufficiently high lateral normal stress.

Several shear pins with different inner diameters were simulated using the finite element model. Those with an inner diameter of 12.4 mm generated a crack that stretched down along the cross section of the pin structure. The crack was then extended to the middle part of the shear pin.

Job Description

Shearing is the process of cutting metals or bars. Generally, shearing is done by a machine. Shears can be used for various purposes, including the manufacturing of products such as pipes, wires, and other components. It also involves the use of hand tools.

The job description of a shearing machine feeder is different from that of a shear operator. This is because shearing machines are used to fulfill specific requirements. As a result, the salary for a shearing machine feeder is often based on the specific location in which the job is performed. Typically, a shearing machine feeder in Dubai may be expected to earn a good income.

This job requires a well-rounded set of skills. One of the most important duties is the maintenance of the workstation. This includes cleaning and storing the tools and equipment that are in use. It also means that you must be alert to any safety hazards.

Other job duties include monitoring the operation of the machine and performing routine maintenance. This may include adjusting the rake (angle) of the blade and adjusting the gap.

The shearing industry in Dubai is a competitive one, especially with several large companies operating in the region. The pay for a shearing machine feeder may vary depending on the type of job and the company that you are applying to. However, some employers may offer you a market-standard salary. Some employers may even offer you a generous gratuity as per UAE labor law.

The most successful shearing machine feeders are adept at both working with the machinery and maintaining it. They are also well-versed in safety and sanitation procedures. They are also accustomed to working in a fast-paced environment.