The integration of lathe machines and robotics is reshaping the manufacturing industry, combining traditional precision machining with modern automation. Lathe machines have been essential in manufacturing for decades, providing the ability to shape and cut materials with high accuracy. With the rise of robotics, these machines have become even more efficient, enabling higher productivity, reduced errors and improved consistency in industrial production.

This article delves into the relationship between lathe machines and robotics, exploring how automation enhances machining processes, its applications in manufacturing and what the future holds for this technological collaboration.

The Role of Lathe Machines in Manufacturing

Importance of Lathe Machines in Industrial Production

Lathe machines are widely used in industries such as automotive, aerospace, defense and heavy engineering. They enable the precise shaping of materials, ensuring that each component meets the required specifications.

Key industrial applications of lathe machines in manufacturing:

- Cutting and shaping metals, wood and plastic

- Machining engine components and machine parts

- Creating threads and grooves for industrial applications

- Producing high-precision medical and aerospace parts

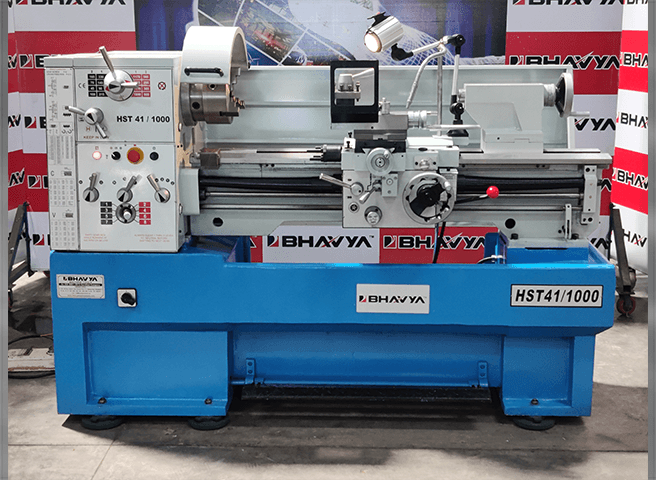

Lathe machines are classified based on their application and design, including light duty lathe machines, medium duty lathe machines, roll turning lathe machines and vertical lathe machines.

Evolution of Lathe Machines: From Manual to Automated Systems

Traditionally, lathe machines required skilled operators to manually control machining processes. However, the advent of all geared lathe machines and CNC (Computer Numerical Control) technology revolutionized their functionality.

- Manual lathe machines – Require human intervention for operation

- All geared lathe machines – Feature automated speed control for enhanced precision

- CNC lathe machines – Fully programmable, reducing reliance on manual labor

Robotics has further enhanced the capabilities of CNC lathe machines, leading to improved efficiency and automation in industrial machining.

How Robotics Enhances Lathe Machines in Manufacturing?

Robotics in Material Handling and Machining

One of the key challenges in manufacturing is handling materials efficiently. Robotics integrated with lathe machines automates this process, reducing the need for manual labor and minimizing human error.

How robotics improves material handling in lathe machining:

- Automated robotic arms load and unload workpieces, reducing downtime

- Sensors ensure precise positioning of materials before machining

- Continuous operation enhances productivity in high-volume manufacturing

For example, in automotive production, robotic systems assist in machining engine components by seamlessly integrating with medium duty lathe machines and roll turning lathe machines.

Robotics in Precision and Quality Control

Robotics improves machining precision by eliminating variations caused by human intervention. Lathe machines paired with robotics can achieve sub-micron accuracy, ensuring uniformity in manufacturing.

Benefits of robotics in lathe machining quality control:

- AI-driven sensors detect defects before machining begins

- Robotic automation ensures every workpiece meets exact specifications

- Smart robotic vision systems enhance quality inspections

This integration is particularly useful in industries like aerospace and medical equipment manufacturing, where precision is critical.

Increased Productivity and Reduced Labor Costs

With robotics, lathe machines operate at optimal speed and efficiency, leading to increased production output.

How automation improves manufacturing productivity:

- 24/7 machining operations without human fatigue

- Faster machining cycles compared to manual operation

- Lower labor costs as fewer operators are needed

For instance, vertical lathe machines used in heavy engineering can be automated with robotic loading and unloading systems, optimizing production flow.

Applications of Robotics in Lathe Machines

Automotive Industry in Lathe Machines

Car manufacturers rely on lathe machines for machining engine components, shafts and transmission parts. Robotics enable 24/7 automated operations, increasing production capacity while maintaining high-quality standards.

Lathe Machines Supports Aerospace Manufacturing

In aerospace, vertical lathe machines are used to produce complex aircraft components. Robotic automation ensures precision machining of turbine blades, landing gear parts and structural components.

Lathe Machines Offers Medical Equipment Production

Robotic-assisted lathe machines manufacture precise medical implants, prosthetics and surgical instruments. These applications require micro-level accuracy, which robotic systems can achieve consistently.

Defense and Heavy Engineering in Lathe Machines

Industries requiring heavy-duty machining, such as defense and mining, benefit from robotics in roll turning lathe machines. Automated systems enhance productivity in large-scale manufacturing while ensuring uniformity in every component.

The Future of Lathe Machines and Robotics in Manufacturing

The fusion of robotics and lathe machines will continue to redefine manufacturing processes. With advancements in AI, machine learning and IoT, lathe machines will become smarter and more autonomous.

Key Trends to Watch:

- Collaborative Robotics: It will work alongside human operators to enhance machining efficiency without replacing skilled labor.

- Predictive Maintenance: AI-powered analytics will predict potential failures in lathe machines, reducing downtime and maintenance costs.

- Adaptive Machining: Robotics will dynamically adjust machining parameters in real time to optimize efficiency and precision.

Conclusion

The integration of robotics with lathe machines is revolutionizing modern manufacturing. By automating repetitive tasks, improving precision and enhancing efficiency, this combination enables industries to meet high production demands without compromising quality.

As robotics technology advances, lathe machines will continue to evolve, making manufacturing smarter, faster and more reliable. Companies investing in robotic-assisted machining will gain a competitive edge, ensuring they stay ahead in an increasingly automated industrial landscape.