The Universal Tool and Cutter Grinding Machine is a specialized piece of equipment designed for precision grinding and sharpening of cutting tools. It offers a wide range of capabilities, allowing manufacturers to produce tools with exceptional accuracy and consistency. This machine is widely used in industries such as aerospace, automotive, and metalworking.

Versatility of Grinding Machine

One of the significant advantages of this machine is its versatility. It can grind a wide variety of cutting tools, including drills, end mills, reamers, and more. This versatility allows manufacturers to consolidate their tool-grinding operations, resulting in increased productivity and cost savings.

A wide range of accessories allows the machine to be used to sharpen a multitude of metal-cutting tools. This makes the machine useful in tool rooms and production plants where a high volume of similar tools needs to be re-sharpened frequently.

In addition, it can also be used for other grinding operations including small cylindrical parts such as chuck jaws, hardened valve seats and tapered pins. This versatility makes the machine a valuable asset in any workshop.

The ability to grind a variety of shapes and angles on the work head of the machine makes it easy to maintain an inventory of tools at optimal performance levels. This translates to improved productivity and reduced operating costs. The machine can grind tools to very tight tolerances, extending their lifespan and helping to ensure that they remain sharp and effective. In addition, the centralized lubrication system ensures that a constant supply of lubricant is available to the workpiece at all times.

Precision of Grinder

Precision is crucial when it comes to tool grinding, and the Universal Tool and Cutter Grinding Machine excels in this aspect. With its advanced control systems and high-quality grinding wheel, it can achieve exceptional levels of precision and accuracy, ensuring that each tool meets the desired specifications.

The Universal Tool & Cutter Grinding Machine is an ideal choice for sharpening and reconditioning multipoint cutting tools. This includes taps, reamers, drills, end mills, gun drills, chamfer cutters, countersink cutters, and engraving cutters. The machine also provides an excellent solution for reconditioning and sharpening single-point cutting tools.

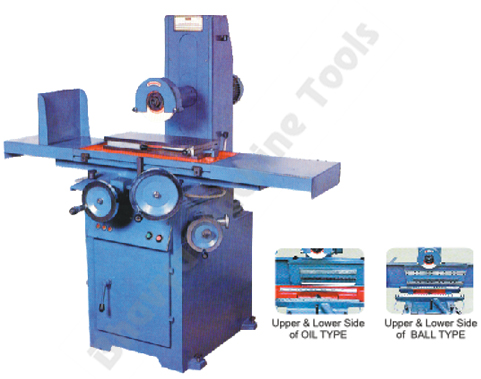

The precision of the grinder is enhanced by the use of angular ball bearings on the spindle support and a grease-lubricated spindle, which ensures that the wheel head can be easily tilted and swivelled in both planes. This makes it easy to set rake and relief angles, which increases accuracy and reduces machining time.

Safety Precautions of Universal Tool and Cutter Grinders

Universal tool and cutter grinders offer versatility with a wide range of attachments and accessories. These include index fixtures, work head swivels, radius attachments, and universal dividing heads. This range of options helps users optimize the machine’s functionality for their specific requirements.

These machines are designed to sharpen and recondition cutting tools, including drills, milling cutters, taps, hobs, and broaches. They can also be used to grind internal surfaces, jig and fixture components, and gauge elements.

All grinding machines can be hazardous to the operator if not properly maintained and used. Incorrect use can result in flying particles, dust, and sparks that can cause severe injury to the operator or anyone else in the immediate vicinity. Ensure that all personnel who will be using the machine have received appropriate training in grinder safety before operating it. Also, all handheld grinders should be equipped with a dead man switch. This prevents accidental activation of the machine during cleaning or maintenance procedures.