A plate bending machine is a device that is used to roll various types of sheet metals into a conical or round shape. This machine has various tools that enable the operator to shape the metal into the desired shape including; round, oval, rectangular, square, and some are circular. There are different types of machines available in the market including; automated plate bending machines, manual bending machines, electric bending machines, and gas bender machines.

Advantages of Plate Bending Machine

Firstly, it is economical equipment as it does not consume too much manpower as well as energy. Secondly, it can produce a large number of bent sheets of different sizes using the same machine. Thirdly, it allows for faster production of the required amount of metal without wastage of the required amount of time. Lastly, the machine produces a quality output that is above the expectation of the customer.

Types of Plate Bending Machine

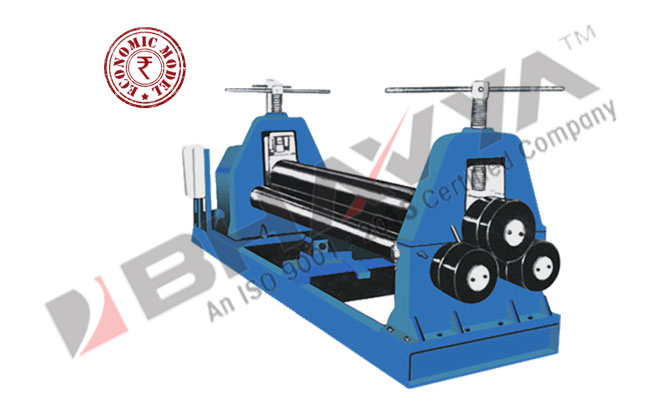

One of the most common types of plate bending machines is the flat plate roller. It uses a continuous feed mechanism to bend thin flat sheet metals. These rollers are capable of producing a wide range of diameters and sizes. Some of them also have the capability of producing thicker and thinner diameters. The thickness produced is directly related to the speed at which the rollers move. Therefore, the speed of the roller is directly related to the amount of metal that has to be curved.

These types of machines are generally small in size and hence consume less energy while operating. They do not require a hydraulic motor because they operate with the help of electricity. This type of equipment also has an automatic service switch that allows the operator to control the speed of the rollers externally. This makes the machine more convenient to use because there is no need for an elaborate service manual. The machine uses an electric motor to bend the sheet and a gearbox to drive the rollers. The gearbox is powered by a chain and it helps to increase the speed of the rollers mechanically.

These are the flat plate machines that are widely used. These include the screw-driven, pre-bend, and screw-driven. All these machines have various advantages. Hence, before buying a plate bending machine, the buyer must decide on the type of machine that he requires.