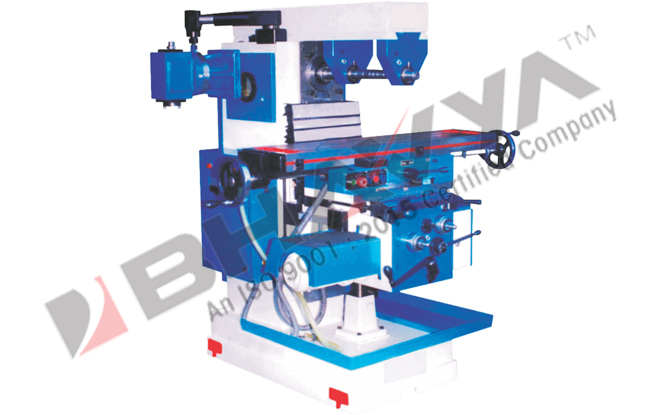

A heavy-duty milling machine is used for the production of large numbers of identical products at a fast rate. In addition, it can also perform other tasks that increase its versatility to any business. When purchasing a milling machine, it is very important to know all the advantages of using them so that you can gain more from them.

Applications of Heavy Duty Milling Machines

With heavy-duty milling machines, your product quality is much better as it can work accurately and quickly. You can save more time because the workload is reduced. These milling machines provide high-quality results as they support accurate data recording and data logging. You have a control panel to measure your machines based on the current status and the performance levels of your rotary table. You can optimize the working speed and the feeds per minute and also reduce the over and under milling of the products.

Advantages of Heavy Duty Milling Machines

With this kind of milling machine, you will get long hours of stable workflow, high speed, accuracy, and consistency in machining operations. The cost of operation of this kind of milling machine is lower than others, so you can save your money. There is no complexity in the operation and it is quite easy to learn the basics of machining processes for an industrial operator. The process of machining is generally dependent on the material being machined and the speed and the type of cutter that is used.

Specifications of Heavy Duty Milling Machines

A heavy-duty milling machine can be of any design and any specifications. However, they all have the same characteristics and some of them have added capabilities to perform other functions. These are very useful for large diameter machining applications. They can perform CNC machining, drilling, deburring, beveling, and engraving and there are many more tools that are useful for these applications.

Various Tasks of Heavy Duty Milling Machines

These machines are designed to perform various tasks and all these tasks can be done at the same time, thereby reducing the cycle times of the machines. You can use this machine for engravings and you can have all the benefits of engraving without any reduction in the quality of the product. The heavy-duty milling machine cuts all types of metal including brass, stainless steel, aluminum, and zinc. It has features like high speed, high precision, accuracy, durability, and minimal operator involvement. There is no need for servicing and tuning up the machine as it requires minimum physical and electrical work.

The Bottom Line

For the fastening of parts and fastening a variety of fasteners like nuts, bolts, rivets, and screws, you can use this heavy-duty milling machine. You will also get the benefit of being able to produce intricate designs in no time and with ease. This machine is perfect for use in CNC machines or computer numerical controlled machines. You can create designs with textured borders and corners and create hollow shapes that are ideal for cutting. You can also perform intricate welding and bonding jobs with this machine.