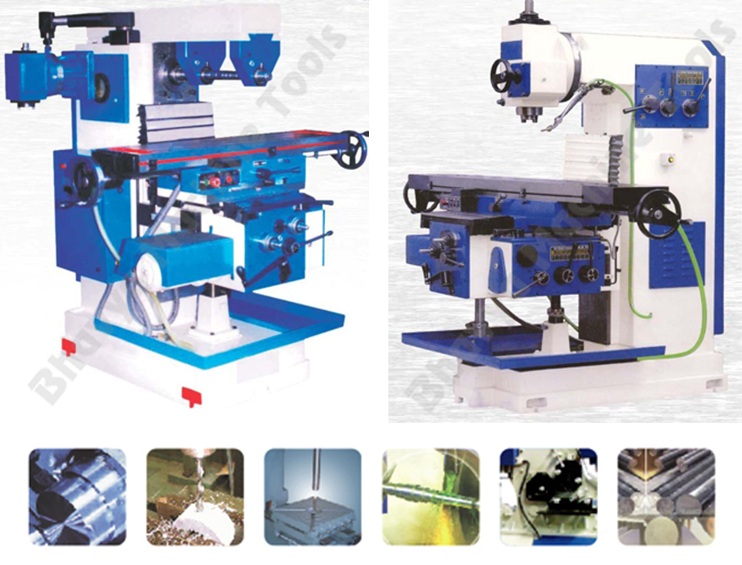

If you are in the keyway milling business, then you should know that it is not an easy business. It involves lots of tedious works such as polishing and grinding to create products that look great. These machines are extremely helpful for the industry. They are very useful as they are fast, accurate, and affordable. They have the ability to create the type of pieces required to finish off projects.

Why Use Keyway Milling Machine?

The process of creating products with these tools can be a lot easier. The main advantage these key-way milling machines offer to the manufacturers is the speed. They can easily make thousands of pieces per hour. This ensures high volume production and that the finished product will be highly consistent in appearance and finish.

This milling equipment is designed for CNC mills. The CNC stands for “Computer Numerated Control”. This is a system that enables users to use software control to control the machines. With this technology, the users have full control over the operation of the machines. They can program specific operations for cutting different materials like brass, aluminum, steel, etc.

Salient Features of Keyway Milling Machine

There is a new design that has been added to the milling machine called the CNC edge mount keyway. This feature increases efficiency and cuts costs as well. With the help of this machine, the process becomes more efficient than before. This milling machine features variable speed and precision CNC milling with a new generation core wire surface technology. This ensures that the cutting is precise all through the process.

The machine also comes with a new generation tooling system called the GIS keyway milling system. With the help of this, you are able to program the keys and then program them into the machine for cutting various materials with ease. The keyways come with a variety of options like nylon, polyester, and many other types of core wires.

Benefits of Keyway Milling Machine

These days, the core wires are made with high and ultra-low-tack resins that ensure high lubricity and flexibility to the core wires. The key-way milling machine is known to offer accurate results along with the best value for money. The milling machine is designed to work with MIG, DWG, NAN, and TIG welding systems. It works on different shaft diameters and thread patterns.

Applications of CNC Milling System

The CNC milling system guarantees accurate and smooth cutting at various degrees of rotation with zero distortion. The CNC milling with the help of this software makes use of computer numerical controlled technology to generate the cutting heads. The software also guarantees precision cutting right through the material at various depths and diameters.

The Bottom Line

This new CNC milling machine with the innovative GIS technology ensures that the cutting heads are perfectly positioned and are not off-center. This way, the chances of cutting errors are reduced and the project is turned out to be successful and profitable.