A cylindrical grinding machine is a crucial tool used in precision engineering, allowing for the grinding of cylindrical or round-shaped parts with high accuracy. In industries such as automotive, aerospace and metal processing, the ability to create highly precise and smooth surfaces on metal workpieces is essential for both functionality and aesthetic purposes. With the right choice, proper operation and regular maintenance, a cylindrical grinding machine can significantly enhance production efficiency and product quality.

This guide aims to walk through how to choose the right machine, operate it effectively and maintain it to achieve maximum precision and productivity in your workshop.

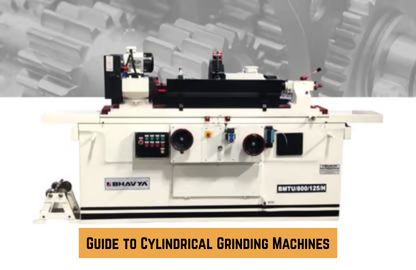

What is a Cylindrical Grinding Machine? Working Principle and Key Components

A cylindrical grinding machine is used to shape the outside of an object. The workpiece is held between two centers and rotated while a grinding wheel is applied to remove material and achieve the desired surface finish. The machine is typically used for tasks that involve cylindrical surfaces, such as shafts, pins and bearing surfaces.

Working Principle:

The key working principle behind cylindrical grinding is abrasive cutting. As the grinding wheel rotates, it makes contact with the workpiece, removing material from the surface in small increments to gradually shape it into a precise cylinder.

Key Components:

- Grinding Wheel: This is the main tool used for cutting the material. It is made up of abrasive particles that grind the workpiece’s surface.

- Workpiece Holding Mechanism: Typically, the workpiece is held between centers or in a chuck. The part is rotated during grinding.

- Hydraulic System: The machine is equipped with a hydraulic system to move the table and control the feed rate.

- Tailstock: This supports the workpiece during grinding, ensuring stability and reducing vibration.

- Cross Feed Mechanism: This is responsible for controlling the movement of the grinding wheel, ensuring even wear and accurate results.

Types of Cylindrical Grinding Machines and Their Industrial Applications

There are different types of cylindrical grinding machines, each designed to handle specific grinding tasks. These include:

- External Cylindrical Grinding Machines: Used to grind the outer diameter of a workpiece, making it ideal for tasks like shaft grinding and bearing surfaces. Commonly found in industries like automotive and aerospace.

- Internal Cylindrical Grinding Machines: These machines are used to grind the inner surface of workpieces such as tubes, housings and cylinders.

- Universal Cylindrical Grinding Machines: Capable of both internal and external grinding, these machines are versatile and used across multiple industries for precision grinding tasks.

- Centerless Grinding Machines: These do not require the workpiece to be held between centers, which allows for high-speed grinding of parts like pins and bushings.

Industrial Applications:

- Automotive: Cylindrical grinding machines are used to create engine components, gears and shafts with high precision.

- Aerospace: The machines are used to grind turbine shafts, aerofoils and other components where exact tolerances are critical.

- Metal Fabrication: Used in the production of high-precision parts for various industrial equipment and machinery.

What Our Customers Say

“My items arrived well packaged and in perfect condition.” .” “The quality of the products exceeds my expectations every time.Trusted industry company. Their product is of the highest quality, and their commitment to sustainability is admirable.”

Procurement RGI On Google

Advantages of Using a Cylindrical Grinding Machine in Precision Engineering

A cylindrical grinder offers several advantages, particularly in precision engineering:

- High Precision: The ability to achieve tight tolerances (up to microns) makes it ideal for precision engineering applications.

- Surface Finish Quality: Provides excellent surface finishes, important for parts that need smooth, uniform surfaces for functionality and aesthetics.

- Versatility: Cylindrical grinding machinery can handle various materials, including steel, brass and stainless steel, making it adaptable to different industries.

- High Productivity: With high-speed grinding capabilities, these machines can efficiently handle large batches of parts without compromising quality.

Cylindrical Grinding Machine vs. Surface Grinding Machine – Key Differences

Both cylindrical grinding and surface grinding machines are used to improve the surface finish of materials, but they serve different purposes:

- Cylindrical Grinding Machines: Primarily used for grinding the external or internal cylindrical surfaces of a workpiece. These machines are ideal for long, round parts such as shafts or pistons.

- Surface Grinding Machines: These machines grind the flat surface of a material. The workpiece is held flat on the table while the grinding wheel removes material from the surface.

How to Choose the Right Cylindrical Grinding Machine?

Selecting the right cylindrical grinding machine depends on various factors:

Workpiece Size: If you are grinding large workpieces, a heavy-duty cylindrical grinding machine will be necessary. Consider the workpiece’s diameter and length to ensure compatibility.

Precision Requirements: If your work requires high precision, opt for a precision cylindrical grinding machine that can handle tight tolerances and deliver exceptional surface finishes.

Material Type: Different machines are suited to different materials. For tougher materials, a metal grinding cylindrical machine with stronger grinding wheels is necessary.

Production Volume: For high-volume production, choose a machine with automated features such as an auto pallet changer or high-speed spindle.

Budget: Higher precision and automated features typically come with a higher price tag. Determine your budget and balance it with the features you need.

Maintenance Tips to Enhance the Life and Performance of a Cylindrical Grinding Machine

Proper maintenance of your cylindrical grinding equipment is essential for ensuring long-lasting performance:

Regular Cleaning: Keep the machine clean by removing debris, metal dust and other contaminants. Clean the grinding wheel regularly to avoid blockages.

Lubrication: Maintain the hydraulic system and moving parts with regular lubrication to prevent wear and tear.

Check Alignment and Calibration: Regularly check the alignment of the spindle and workpiece centers to ensure accurate grinding.

Inspect Grinding Wheels: Check for wear on the grinding wheel and replace it when necessary to maintain cutting efficiency and precision.

Industrial Applications of Cylindrical Grinding Machines in Automotive and Aerospace

In industries like automotive and aerospace, precision is paramount. Cylindrical grinding machines are used to produce high-precision components that meet stringent industry standards, such as:

- Engine Components: Cylindrical grinding is used to manufacture pistons, crankshafts and camshafts.

- Aerospace Components: Machines are used to grind turbine shafts, actuator rods and engine components to ensure proper functionality and performance in high-stress environments.

Common Problems in Cylindrical Grinding Machines and How to Troubleshoot Them

Some common issues that may arise in cylindrical grinding machines include:

- Inconsistent Surface Finish: This may be caused by worn-out grinding wheels, misalignment or incorrect feed rates. Solution: Regularly inspect the grinding wheel and recalibrate the machine.

- Overheating: Excessive heat buildup can occur if the coolant system isn’t functioning properly. Solution: Check the coolant levels and ensure the system is circulating fluid effectively.

- Vibrations: Vibrations can lead to poor surface finishes. Solution: Ensure the machine is on a stable surface and check for wear in the bearings or spindle.

Latest Technological Innovations in Cylindrical Grinding Machines

Recent advancements in cylindrical grinding machinery have led to the development of machines with enhanced precision, automation and efficiency. These include:

- Automation Features: Integration of robotic arms and auto pallet changers to increase productivity and reduce labor costs.

- Advanced CNC Controls: Modern CNC cylindrical grinding machines feature advanced digital controls, enabling faster setup times and more complex grinding operations.

- High-Speed Spindles: New machines feature faster spindle speeds, reducing cycle times and increasing production rates without sacrificing quality.

How Cylindrical Grinding Machines Improve Accuracy in High-Volume Production?

Cylindrical grinding machines are crucial in high-volume production environments where consistency and accuracy are key. These machines can consistently produce parts with tight tolerances, reducing the need for secondary operations and improving overall efficiency. Features such as multi-axis CNC controls and precision back gauges allow for rapid, accurate and repeatable results, ensuring that each component meets stringent quality standards.

Conclusion

Choosing, operating and maintaining a cylindrical grinding machine requires careful consideration of your workshop’s needs and requirements. From understanding the key components and selecting the right machine for your material and precision requirements to ensuring proper maintenance for maximum productivity, following the best practices outlined in this guide will help you optimize your cylindrical grinding machinery for maximum precision and efficiency.

FAQs: About Cylindrical Grinding Machine

How do I choose the right cylindrical grinding machine?

Choose based on workpiece size, precision requirements, material types and production volume. For high precision and complex tasks, select a CNC cylindrical grinding machine.

What is the key difference between cylindrical grinding and surface grinding?

Cylindrical grinding is used for round workpieces, while surface grinding is for flat surfaces. Cylindrical grinding machines are ideal for parts like shafts and bearings.

How often should a cylindrical grinding machine be calibrated?

Calibration should be performed regularly, especially when high precision is required. Checking alignment and calibration after every few hundred hours of operation is ideal.

What materials can be processed with cylindrical grinding machines?

Cylindrical grinding machines can process materials such as stainless steel, mild steel, brass, copper and aluminum.

What is the advantage of CNC cylindrical grinding machines over NC models?

CNC cylindrical grinding machines offer more flexibility, higher precision and the ability to perform complex grinding tasks automatically, making them ideal for high-volume production.