Slotting machines are essential tools in the manufacturing industry used for creating keyways, grooves and slots in various materials. These machines utilize a vertical ram that moves up and down, cutting into the material as it moves. Slotting machines are categorized based on their size, power and capacity into light-duty and heavy-duty versions, catering to different manufacturing needs. Whether you’re working on small-scale, high-precision projects or large, heavy-duty operations, understanding the difference between light duty and heavy-duty slotting machines is crucial for making the right equipment choices for your business.

In this article, we’ll break down the features, specifications and applications of light-duty slotting machines and heavy-duty slotting machines, allowing you to determine which machine best suits your business needs.

What is a Slotting Machine?

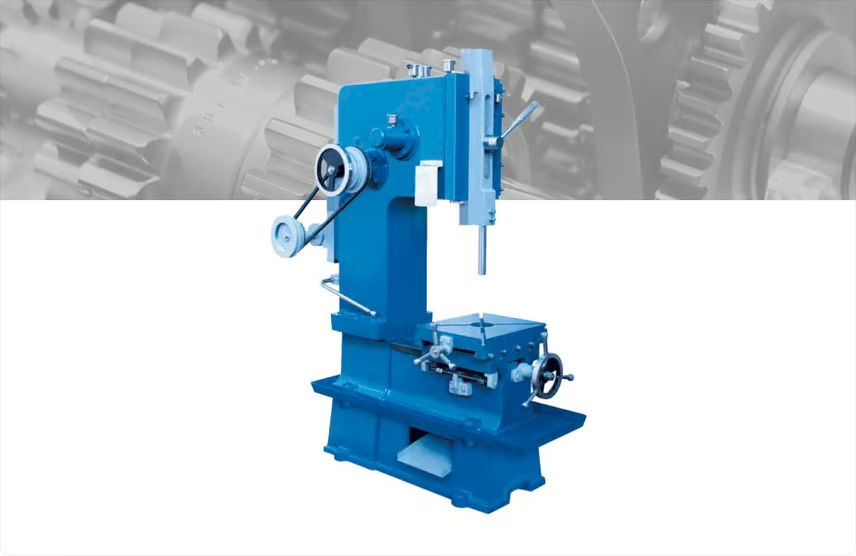

A slotting machine, also known as a vertical shaper, is a machine tool used to cut grooves, keyways, or slots into workpieces. It operates through a vertically moving ram that holds a single-point cutting tool. This machine is especially useful for cutting internal and external keyways, flat surfaces and grooves on parts that require high precision.

Slotting machines are available in a range of configurations, from light-duty models suitable for smaller workpieces to heavy-duty machines that can handle larger and more complex tasks. Understanding the specifications and capabilities of both light-duty and heavy-duty slotting machines can help businesses select the right equipment based on their manufacturing requirements.

Light Duty Slotting Machines: Overview and Specifications

Light-duty slotting machines are ideal for tasks that require moderate cutting capacity and precision. These machines are designed to handle small to medium-sized workpieces, typically made of softer materials. They offer a variety of features aimed at ensuring smooth operation, ease of use and reliability. Light-duty machines are commonly used in small workshops or in industries that do not require heavy cutting forces.

Models of Light Duty Slotting Machines

Here are some of the popular models of light-duty slotting machines:

- BS-150

- BS-250

- BS-300

Each model comes with unique specifications that cater to different production requirements.

Specifications and Features of Light Duty Slotting Machines

Stroke Range:

The light-duty slotting machines provide adjustable strokes that vary across models. For example:

- BS-150 has a stroke range from 10 to 150 mm.

- BS-250 has a stroke range from 10 to 250 mm.

- BS-300 offers an adjustable stroke range from 10 to 300 mm.

This feature allows operators to adjust the depth of the cutting tool to meet different cutting requirements.

Longitudinal and Cross Movements:

- The BS-150 provides 200 mm of longitudinal movement and 110 mm of cross movement.

- The BS-250 offers 230 mm of longitudinal movement and 110 mm of cross movement.

- The BS-300 allows for 300 mm of longitudinal movement and 110 mm of cross movement.

These movements ensure that the workpiece can be accurately positioned for a precise cut.

What Our Customers Say

“Good service. Providing full and real information before delivering the product.I purchased lathe machine and many more products from Bhavya.From Gujrat to Kashmir long distance, with proper packaging received lathe machine 100% in good condition.Worked on machine,The accuracy is too good. Thanks Team Bhavya”

Nasir Hayat On Google

Speed Adjustment:

All models come with 3-speed adjustment settings, providing flexibility in selecting the optimal cutting speed for different materials.

Ram Adjustment:

- The BS-150 features a ram adjustment of 150 mm.

- The BS-250 provides 250 mm of ram adjustment.

- The BS-300 offers 300 mm of ram adjustment.

This feature helps ensure a smooth operation by adjusting the cutting tool’s position relative to the workpiece.

Motor Power:

The motor power varies according to the model, from 1 HP for the BS-150 to 2 HP for the BS-300. The motor power ensures that the machine has sufficient strength for light-duty operations without overloading.

Column to Ram Distance and Table to Ram Distance:

The BS-150 has a column-to-ram distance of 210 mm and a table-to-ram distance of 310 mm, making it suitable for smaller workpieces. The BS-250 has a larger column-to-ram distance of 330 mm and a table-to-ram distance of 410 mm. The BS-300 offers even more flexibility with 495 mm of column-to-ram distance and 430 mm of table-to-ram distance.

Table Size and Dimensions:

- The BS-150 and BS-250 have a table size of 280×335 mm.

- The BS-300 has a slightly larger table size of 360×305 mm.

The table size ensures that the workpiece can be securely held during the operation, ensuring smooth cutting and stability.

Machine Dimensions and Weight:

The BS-150 weighs 375 kg, making it a compact option for smaller workshops. The BS-250 weighs 450 kg and the BS-300 weighs 550 kg, which are slightly larger but still suitable for medium-scale production.

Accessories and Features

- Rotary Table: The machines come with a rotary table with a 36:1 ratio, which enables easier positioning of the workpiece during cutting.

- Electric Motor and True Chuck: All models come with a true chuck and an electric motor for easy control of the machine’s power.

- V-Belt: A V-belt ensures efficient transmission of power from the motor to the ram.

These features help ensure that the machine operates smoothly and accurately, providing high-quality output for light-duty applications.

Heavy Duty Slotting Machines: Overview and Specifications

Heavy-duty slotting machines are designed to handle larger, more robust workpieces, often requiring higher power and more significant cutting forces. These machines are typically used in industries that manufacture large mechanical components, such as gears, spindles and other high-strength parts. Heavy Duty Slotting Machines are capable of cutting tougher materials and are ideal for industrial-scale manufacturing.

Models of Heavy Duty Slotting Machines

Some common models of heavyduty slotting machines include:

- BHS-10

- BHS-10-13

- BHS-12-14

- BHS-14-16

- BHS-16-18

These models vary in their stroke size, rotary table dimensions, motor power and other features, making them suitable for different types of heavy-duty applications.

Specifications and Features of Heavy Duty Slotting Machines

Stroke Range:

The heavy-duty slotting machines have much larger stroke ranges, which are critical for cutting larger workpieces:

- The BHS-10 has a stroke of 10”.

- The BHS-10-13 offers a 10” to 13” stroke.

- The BHS-30-32 offers a stroke range of 30” to 32”.

Rotary Table Dimensions:

- The BHS-10 comes with a 15” rotary table.

- The BHS-30-32 offers a 30” rotary table, accommodating larger and heavier workpieces.

Longitudinal and Cross Movements:

Heavy-duty slotting machines offer extensive movement ranges:

- The BHS-10 offers 12” of longitudinal movement and 9” of cross movement.

- The BHS-30-32 offers 22” of longitudinal movement and 18” of cross movement.

Cutting Speed of Ram:

Most models come with a cutting speed of 2 to 4 NO (number of speeds), ensuring flexibility for various cutting operations.

Ram Adjustment:

The BHS-10 offers 11” of ram adjustment, while the BHS-30-32 offers up to 22” of adjustment, allowing for significant depth control during cutting.

Motor Power:

The motor power required increases significantly in heavy-duty models. The BHS-10 requires 2 HP, while the BHS-30-32 requires up to 10 HP, ensuring sufficient power for tough cutting tasks.

Throat Depth and Column to Main Column Distance:

These machines also offer greater throat depths and larger distances from the tool to the main column:

- The BHS-10 offers a throat depth of 17”.

- The BHS-30-32 offers a throat depth of 24”.

Machine Weight and Dimensions:

These machines are much larger and heavier, weighing between 450 kg and 2,000 kg, depending on the model. Their larger size provides stability during operation, especially when working with heavy parts.

Applications of Heavy Duty Slotting Machines

Heavy-duty slotting machines are used in industries such as:

- Aerospace: For manufacturing large, precise components.

- Automotive: For cutting keyways and grooves in heavy parts like gears, axles andshafts.

- Marine: For creating intricate slots and grooves in large mechanical parts.

These machines are designed to handle large-scale, tough jobs, offering high accuracy and durability.

Choosing Between Light Duty and Heavy Duty Slotting Machines

Choosing between light-duty and heavy-duty slotting machines depends largely on your business’s specific requirements, including the size of your workpieces, the precision needed and the volume of production.

- Light-duty slotting machines are perfect for smaller parts and lighter materials, offering flexibility, ease of use and faster production for tasks such as keyway cutting in softer materials.

- Heavy-duty slotting machines are essential for larger, tougher materials and industrial-scale production. They provide the power, stability and precision required for complex tasks such as cutting deep slots, grooves and keyways in high-strength materials.

By understanding the features and applications of each type, businesses can ensure they select the appropriate machine to meet their manufacturing needs.

Conclusion:

In conclusion, Light-duty machines are ideal for smaller, less complex tasks with softer materials, offering speed and efficiency. On the other hand, heavy-duty machines provide the power and stability required for larger, more demanding workpieces, ensuring precision in industrial-scale applications. By understanding your specific requirements, you can select the machine that best suits your business’s needs, optimizing both productivity and quality.

FAQs about Light & Heavy Duty Slotting Machines

What’s the key difference between light-duty and heavy-duty slotting machines?

Light-duty machines are designed for smaller, softer materials, while heavy-duty machines handle larger, tougher workpieces with more power.

Which industries use heavy-duty slotting machines?

Industries like aerospace, automotive and marine use heavy-duty slotting machines for cutting large, precise components.

What materials are light-duty slotting machines best for?

Light-duty slotting machines are ideal for softer materials like mild steel, aluminum and brass.

How do I choose the right slotting machine for my needs?

Choose based on the size and complexity of your workpieces - light-duty for small, high-speed tasks and heavy-duty for larger, tougher materials.

Can a light-duty slotting machine handle larger parts?

Light-duty machines are better suited for smaller parts and may not be ideal for larger, heavy workpieces.