Vehicle Manufacturing – the Major Sector that depends on Machining

Automobile companies are the major metal product users for producing different parts. Steel and aluminium are two major components. Apart from this, fibre and plastics are also considered for making varieties of transport. Major luxury motor making companies are making cars aluminium for body that gives a classic look for the transport product. Manufacturers use this ingredient because it is strong and is affordable in the market and moreover, product can be engineered in different shapes and need of crash safety. Approx 65% of vehicle parts are made up of metal products. Steel is a kind of element which has flexibility and qualities that leads to its usage in affordable way. There are machines that are used by manufacturing companies to create the required design for manufacturing.

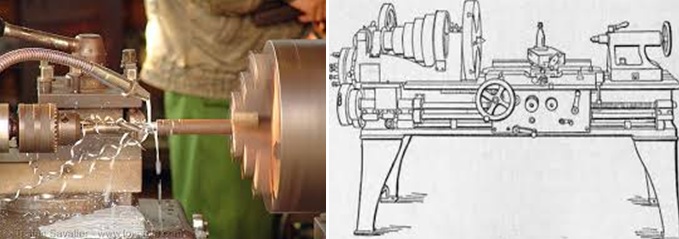

Machines to Design Metal

Industries use various machines for forming different components required for manufacturing, one such is lathe device. Automobile industry are using this tools to get the desired shape and cut of components. Different types of lathes are used for shaping plus cutting the raw material such as, engine, turret, and special purpose lathes. Today, bigger range of workshop tools is used by makers.

Machining Equipments used in Production

There are many modern machining types of equipment for shaping and cutting materials which are eventually applied in automobile production. Some of them are:

- Lathes

- Drill

- Mill

- Hobbing apparatus

- Honing device

- Gear shapers

The user uses these devices as per the requirement and how these modern styles of tools can be used.

Varieties in Machined products Applied

- Steel: Most part of the auto product including steering and suspension are made from this. Moreover, stainless steel is also used for auto built-up because of non-rusting property.

- Aluminium: There is a big transition happening from the above material to this one in vehicle production. Though this raw ingredient cost double than the one made from the top component, but it brings a major change in the design. The reason behind this change is its light weight. Parts that are completed by using aluminium are engine and wheels.

- Iron: This is next big material used in creation after the top preferred ones. Moreover, the weight of iron makes the usage more sufficient.

- Titanium: This is strong, light weight and corrosion resistant. It is quite hard to manufacture, but is generally considered for intake and exhaust valves.

Making of Luxury Cars

Car manufacturers are now using advanced high-strength steels to make strong body. Luxury car makers are also using aluminium which is less dense material and saves 11% on making the body. For this base material, the market is very competitive for car manufacturing. Presently, advanced high potency form is largely used materials in automotive business. Metal industry has evolved greatly, and so the makers are using different forms of such products to manufacture high class design travelling product structure with the help of machining tool and lathe is one among the important requirements which is preferred for majority of creation requisites by makers.

Conclusion:

There is no doubt that metal is an important component in designing the means of transport structure. Automobile engineering is evolving dramatically and so are the machining trade introducing versatile tools for long run and getting desired shapes of the same.