This article focuses on the high-power fiber laser and its applications in micro-cutting and thin-sheet applications. It also discusses the initial costs and operating costs of this machine. This article will help you to make an informed decision. We will explore some of the key trends affecting the global fiber laser cutting machine market.

High-Power Fiber Lasers for Cutting

The growth of the automobile and mobile electronics industries are the key drivers of the fiber laser market. Furthermore, rising disposable income across the world is spurring the adoption of high-power fiber lasers. Thus, this market is expected to grow at a rapid pace. In the Asia-Pacific region, China is expected to be the fastest-growing market for fiber lasers.

The High-Power Fiber Laser market is anticipated to exceed USD million in 2022, growing at an Impressive CAGR during the forecast period. This report offers detailed insights into the market’s demand and supply trends, as well as its challenges and opportunities. It also includes profiles of key players operating in the market.

As high-power fiber lasers are highly efficient, compact, and eco-friendly, they are becoming increasingly popular among industrial and consumer markets. The growth of high-power fiber lasers is also fueled by the growing use of these devices in the military and automotive sectors. Furthermore, fiber lasers have numerous uses in the medical, biomedical, and industrial sectors.

Fiber lasers use optical fiber cables or silica glass cable to emit a light beam. This results in a beam that is thinner and straighter than with other lasers. Additionally, these lasers are highly efficient and require less cooling than conventional lasers. Other benefits of fiber lasers include their low operating cost, low maintenance, and a small footprint.

High-power fiber lasers are primarily used in industrial applications, such as marking, engraving, printing, welding, and cutting. Numerous OEMs have also begun using high-power fiber lasers for 2D cutting. In addition, they are being used in advanced applications such as obstacle ranging, directed energy applications, and remote sensing.

Fiber Laser Machine Application in Thin-Sheet

Fiber lasers are extremely effective in cutting stainless steel and thin sheets. In fact, they can achieve speeds of up to 6 times faster than CO2 lasers. For example, a fiber laser can cut a five-mm-thick sheet at a rate of up to 2 m/s.

A recent innovation aimed at enhancing the performance of fiber lasers has been a beam-shaping technology. This technology is capable of enhancing the cutting speed and quality of thin sheets by making the beam more versatile. In addition, it can be used to cut a wider variety of materials.

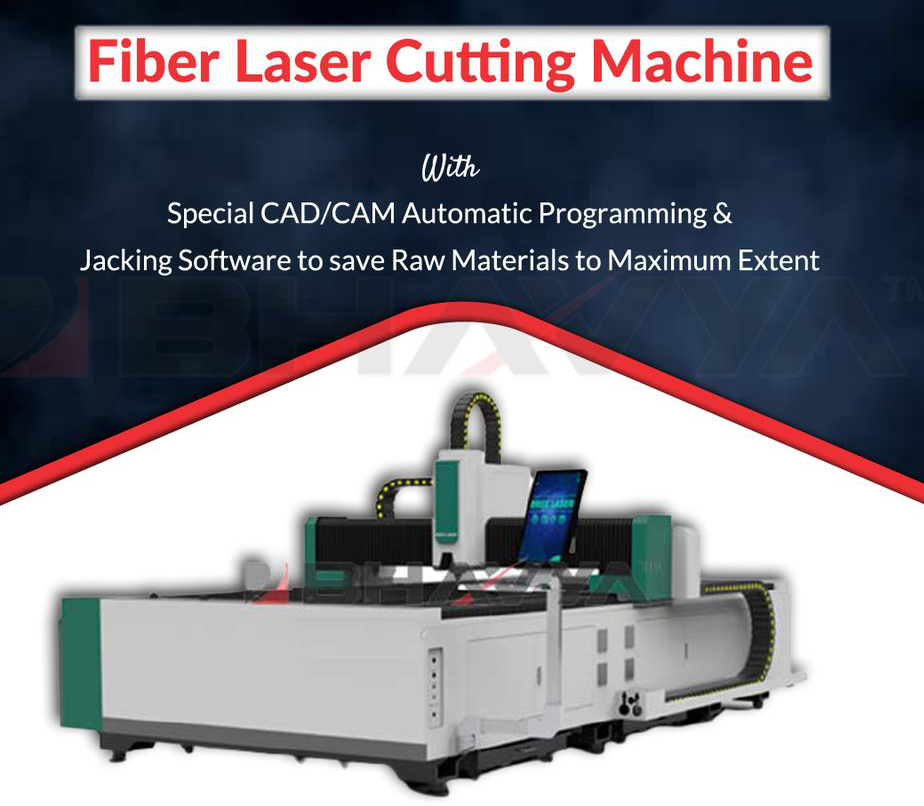

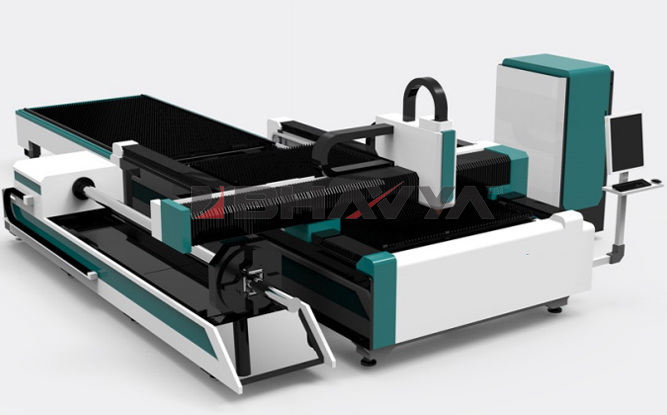

High-power fibre laser cutting machines are able to process metal plates, electrical cabinets, machine cases, and more. Their speed and accuracy make them an excellent choice for many industries. These machines feature automatic zoom cutting head with lens monitoring, automatic focal point adjustment, and edge search and layout. They are also highly efficient and compact.

The cutting speed varies according to the material being cut. The highest cutting speed is achieved when the material is thinner. However, cutting speed decreases with increasing material thickness. In addition to the maximum speed, the cutting depth and beam focus position affect the cutting speed. Moreover, laser power density is also related to the speed of the gas jet.

Micro-Cutting Applications with Fibre Laser Machine

This laser cutting machine is based on CNC system, which has a fast interpolation operation speed and an easy-to-use interface. Its servo system has excellent dynamic performance and a strong load capacity. The laser beam is focused onto the work piece through a high-quality lens. The quality of the focused beam will determine the size of the focused spot.

Compared to other methods of cutting metal, fibre laser cutting offers superior precision and greater part throughput. It is also more efficient and produces less waste. As a result, it is increasingly becoming the standard in metal manufacturing. Furthermore, it can be up to 10x faster than other processes.

Optical fibers are also an excellent option for cutting materials with a high degree of complexity. Since fiber optics are less prone to breakage than mirrors, they are an excellent choice for machining micro-scale features. Moreover, fiber laser cutting machines can create single-sided features with small internal radii.

Another important factor in the quality of the cut is the center of the nozzle. The nozzle’s center must be calibrated to maintain concentricity. If the nozzle is fouled or deformed, the quality of the cut may be adversely affected.

Operating Cost of Fiber Laser Cutting Machine

While the initial cost of a fiber laser cutting machine is the most important consideration for purchasing one, it is also important to understand the operating costs as well. These costs are directly related to time and material. The longer the cutting time, the more expensive it is, while shorter cutting times result in lower costs.

In addition to initial investment, an effective Fiber laser cutting machine should be able to reduce the operating costs. It should be compact and easy to integrate into production lines. Additionally, it should have a high level of handling flexibility and tailor-made software to optimize the operation of the machine. In addition, it must come with adequate support. For example, it must be capable of addressing problems that occur due to deterioration of cut quality, damaged consumables, and machine malfunctions.

A fiber laser cutting machine also has fewer consumables than CO2 or plasma cutting machines. However, a fiber laser cutting machine is not maintenance-free and may need to be serviced occasionally. Service contracts can be purchased with the manufacturer, and these service plans vary in price.

In addition to initial costs, the operating cost of a fiber laser cutting machine is also determined by its productivity. High-powered machines, on the other hand, offer higher throughput and complete more work per hour.

Automation and robotics are essential in cutting metal materials. These technologies have increased the efficiency of production and result in lower operational costs. This is a great way to cut costs while achieving the desired quality.

Drivers of Fiber Laser Machine Market Growth

There are several factors that are driving the growth of the fiber laser cutting machine market. These factors include the increased adoption of advanced Laser cutting machines, which help in increasing production, improving precision and reducing cost. One of the major factors supporting the growth of this market is the rapid industrialization of the region. According to the significant reports, India is expected to manufacture $300 billion worth of electronic goods in FY 2022-2023.

The Fiber Laser Cutting Machine market is expected to grow at a significant CAGR. Its scope and applications are growing globally. The region-specific drivers are automotive manufacturing, medical devices, and aerospace, which are driving the demand for laser cutting machines. Several companies in the region are operating in these sectors. Moreover, the region has favorable conditions for production operations and a strong infrastructure base. As a result, it is expected to be the fastest-growing segment of the global laser cutting machine market.

The Bottom Line

Fiber laser cutting technology is a fast, accurate, and flexible tool for cutting sheet metal. It eliminates the need for moulds and saves on manufacturing costs and labour intensity. In fact, it has been widely adopted by various metal processing industries. By utilizing fibre laser cutting technology, manufacturers are able to reduce their production costs and boost efficiency.