Fiber laser cutting technology has rapidly become a cornerstone of modern sheet metal fabrication. This advanced cutting method offers unparalleled precision and efficiency, enabling manufacturers to create high-quality components for a variety of industries. In this article, we explore how fiber laser cutting is applied across multiple sectors, providing a detailed look at the practical uses and importance of this technology in the sheet metal industry.

How Fiber Laser Cutting is used in the Automotive Industry?

In the automotive industry, where precision and speed are critical, fiber laser cutting technology is widely employed to manufacture a variety of vehicle components. These include structural parts, body panels, exhaust systems and more. The ability to handle different metals and deliver high-quality cuts makes fiber laser cutting an ideal solution for automotive fabrication.

Applications:

- Cutting chassis components and body panels

- Manufacturing complex vehicle parts (e.g., brackets, reinforcements)

- Producing exhaust systems, seat frames and suspension components

Fiber laser cutting machine allows automotive manufacturers to produce intricate components with high accuracy and minimal waste, streamlining production processes while maintaining product quality.

Why Fiber Laser Cutting is Essential for the Aerospace Industry?

The aerospace industry demands materials that can withstand extreme conditions while maintaining precise engineering. Fiber laser cutting is a key technology used to fabricate high-precision parts, such as turbine blades, engine components and structural frames. The ability to cut through tough materials like titanium and high-strength alloys with minimal distortion makes fiber laser cutting indispensable for aerospace applications.

Applications:

- Manufacturing aerospace structural components (e.g., fuselage frames, wing spars)

- Cutting turbine blades and engine parts

- Producing components for landing gear, brakes and other critical systems

By ensuring precise cuts and minimal material deformation, fiber laser cutting contributes to the high performance and safety standards required in aerospace manufacturing.

When Fiber Laser Cutting is used in the Electronics Industry?

The electronics industry relies on fiber laser cutting for the production of small, detailed components used in consumer electronics, medical devices and industrial equipment. Fiber laser machines are ideal for cutting intricate parts with fine tolerances and minimal thermal impact, which is critical for preserving the integrity of delicate electronic components.

Applications:

- Cutting components for circuit boards, connectors and sensors

- Producing metal enclosures and housings for electronic devices

- Manufacturing parts for mobile phones, laptops and wearable devices

Fiber laser cutting is particularly useful for the high-precision and low-thermal-damage requirements of the electronics sector, enabling fast and accurate production of complex parts.

How Fiber Laser Cutting Contributes to the Construction and Architecture Industries?

In the construction and architecture sectors, fiber laser cutting technology is applied to create customized metal components used in building facades, bridges and structural elements. The ability to quickly and precisely cut metal allows for creative design flexibility, while also meeting the rigorous demands of construction projects.

Applications:

- Fabricating metal panels for building facades, gates and railings

- Creating decorative architectural signage and elements

- Cutting structural steel beams and reinforcement plates

Fiber laser cutting’s high speed and precision make it a key tool for meeting the tight deadlines and complex specifications often found in large-scale construction and architectural projects.

Why Fiber Laser Cutting is Ideal for Sheet Metal Parts in Metalworking and Fabrication?

Metalworking and fabrication industries heavily rely on heavy-duty fiber laser cutting to produce a wide range of sheet metal parts. From tools and brackets to structural components and panels, fiber laser cutting is used to quickly and accurately fabricate these parts, improving production efficiency and ensuring consistency.

Applications:

- Cutting sheet metal parts for industrial machinery

- Manufacturing panels, frames and housings for consumer goods

- Producing components for various industries like manufacturing, automotive and construction

The ability of fiber laser machines to handle high-volume production runs and produce high-quality, repeatable results is crucial for fabricators looking to improve their operational efficiency.

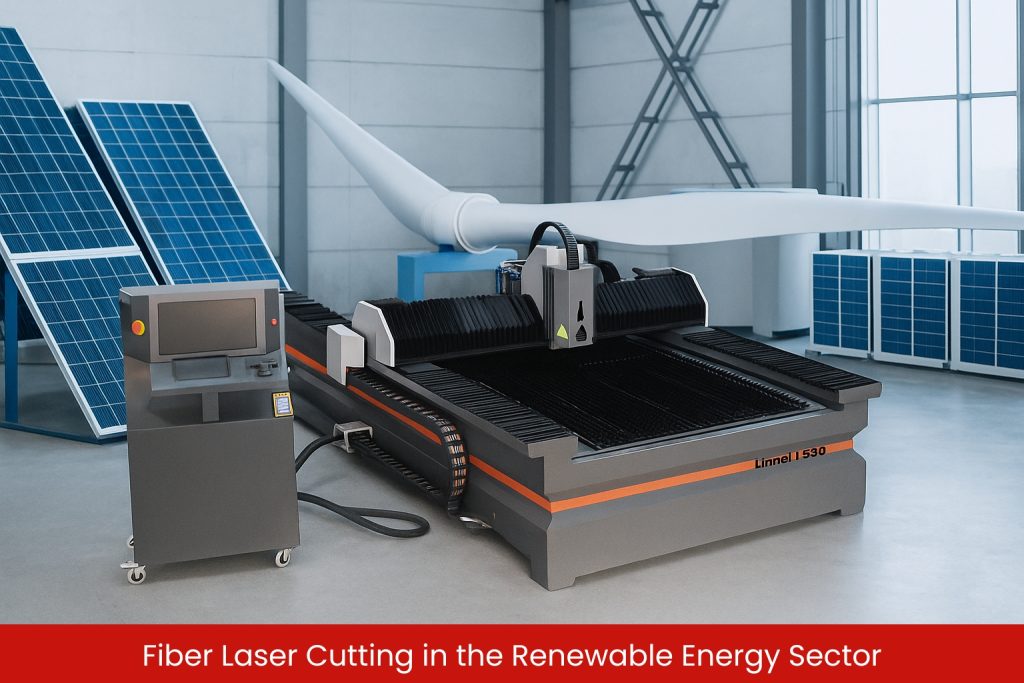

When to Use Fiber Laser Cutting in the Renewable Energy Sector?

The renewable energy industry benefits from fiber laser cutting, especially in the production of components for solar and wind power systems. Fiber lasers are used to cut metal parts for solar panel frames, turbine blades and energy storage systems, ensuring precision and durability in these critical energy components.

Applications:

- Cutting metal components for solar panel frames

- Fabricating parts for wind turbine blades and towers

- Producing components for energy storage systems and enclosures

As renewable energy systems require high-quality, durable parts, fiber laser cutting helps meet these demands by providing precise, clean cuts in a range of materials used in energy generation.

How Fiber Laser Cutting is Shaping the Medical Industry?

In the medical sector, where precision and reliability are critical, Fiber Laser Cutting is used to produce surgical instruments, implants and medical devices. The technology’s ability to make precise cuts without causing thermal damage is particularly important in the manufacturing of medical components.

Applications:

- Cutting surgical instruments and medical implants

- Fabricating medical device enclosures and housings

- Producing fine-cut components for diagnostic equipment

Fiber laser cutting ensures that medical parts are produced with high precision, which is crucial for maintaining the functionality and safety of medical devices.

Why Fiber Laser Cutting is Crucial in the Shipbuilding Industry?

The shipbuilding industry relies on fiber laser cutting for producing large, complex parts used in the construction of ships, submarines and offshore platforms. The ability to cut thick plates of metal with high accuracy and speed makes laser fiber cutting machine an invaluable tool for marine manufacturing.

Applications:

- Cutting structural components for ships and marine vessels

- Fabricating parts for offshore platforms and naval ships

- Manufacturing metal fittings and accessories for marine applications

Fiber laser cutting’s ability to produce high-quality cuts on thick materials ensures that shipbuilding operations are both efficient and precise.

Conclusion

Fiber laser cutting technology has found extensive applications across various industries, from automotive and aerospace to electronics, construction and renewable energy. Its precision, speed and ability to handle a wide variety of materials make it indispensable for sheet metal fabrication. As industries continue to evolve, fiber laser cutting remains a key technology, driving innovation and efficiency in manufacturing processes.

FAQs about Fiber Laser Cutting Machine

How does fiber laser cutting improve precision in manufacturing?

Fiber laser cutting uses a focused laser beam to make precise cuts in metal, ensuring high accuracy and smooth edges, which reduces the need for further processing.

Why is fiber laser cutting preferred in industries like aerospace and automotive?

Fiber laser cutting provides high precision, minimal distortion and the ability to handle complex geometries, which are crucial for the strict quality standards of industries like aerospace and automotive.

When is fiber laser cutting used in the electronics industry?

Fiber laser cutting is used in the electronics industry to produce small, intricate components like circuit board parts, connectors and enclosures, requiring high precision and minimal thermal damage.

How does fiber laser cutting benefit the shipbuilding industry?

Fiber laser cutting allows for high-speed, precise cutting of thick metal plates, essential for producing large, complex components used in shipbuilding and offshore platform construction.

Why is fiber laser cutting important in renewable energy production?

Fiber laser cutting is crucial for manufacturing components used in solar panels, wind turbines and energy storage systems, offering precision and durability for critical parts in renewable energy infrastructure.