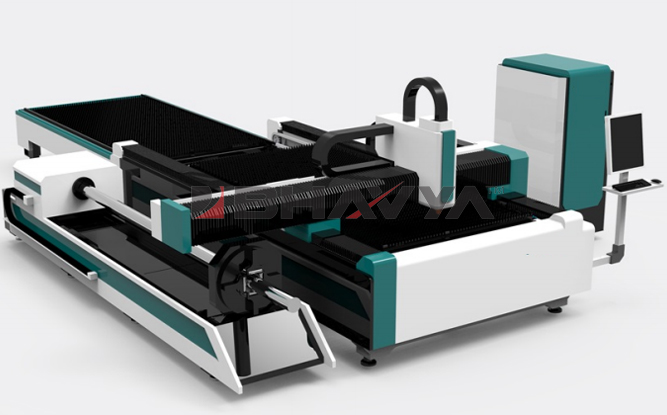

Fibre laser cutting machine is now a popular innovative laser-cut style that adopts fibre optic connection to meet accurate, smooth, and precise cutting results. These machines are now the choice for many industries that require smooth cutting without a lot of human involvement and also produce less waste. These lasers are also a class of high-intensity pulsed light that is rapidly rising in the metal cutting field.

Working Principle of Fibre Laser Cutting Machine

In general, there are two kinds of cuts possible with this kind of machine. They are the direct and alternating current cuts. In the direct current cutting system, the saw blade is fixed at an angle which results in heat being generated. With the alternating current system, blades are connected at regular intervals to generate a continuous current instead of the direct current one. The main advantage of this kind of method over other methods is that it provides very little distortion to the cut sheet metals.

Features to Consider While Buying Fibre Laser Cutting Machine

A high-quality cutting machine offers fast cutting speed with high-quality accuracy in cutting materials. To attain this, it has to be of high quality and made of durable material. High-quality and durable products are essential for ensuring that the product is cut properly and safely. The cut-rate and accuracy of these fibre laser cutting machines are determined by various factors such as the materials to be cut, the distance of the blades from the work surface, blade life, etc.

For example, metals like stainless steel need to be cut to precise tolerance levels for maintaining their end-user applications. Therefore, if you are looking for high quality, long-lasting, and easy-to-use product, you must go for a fibre laser cutting machine that is designed to cut stainless steel or other stainless steel alloys. It must be made sure that you get the best results and get the right specifications for your application. This can be achieved by using the best material and manufacturer that can provide you with the desired results.

A good manufacturer like Bhavya Machine Tools can give you the best product based on your requirements. We can analyze the type of cut you need, the required parameters, and the amount of money you can afford to spend. Based on these factors, we manufacture the appropriate machine that meets your specifications and budget. We also guide you on how to operate the machine, what type of feedstock do you require, etc. Another important point that must be considered before purchasing a fibre laser source is that it should give you an automatic feed slide that allows for the smooth functioning of the machine. It should also allow for maintenance, lubrication, and even easy replacement of parts. You must get theses things right so that you can get the best results that you want out of the machine.