In this article, we will look at the features, functions, and specifications of the High-Speed Precision Lathe Machine. We will also discuss the price and the specifications. In the end, you will be able to buy the perfect machine for your workshop. We hope that this article will be helpful in your search for the perfect machine. Please feel free to contact us if you have any questions. Until then, please browse through our other articles and find the best machine for your needs.

Features of High-Speed Precision Lathe Machine

A high-speed precision lathe machine is a highly accurate and automated device that is widely used in the manufacturing industry. It is capable of creating intricate objects from one piece of material. They are programmed to produce near-finished objects without the need for manual supervision. They have contributed to the industrial revolution since the early days of the industrial age. The following are some features of a high-speed precision lathe machine.

Light-duty and heavy-duty models are available to cater to different requirements and budgets. Light-duty models are easy to set-up and use. They are highly efficient in enabling and assembling operations and can replace manual labor. These machines can be purchased at competitive prices and are thoroughly checked before shipping to ensure fault-free performance at the client’s end. To get more information, visit a manufacturer’s website.

Functions of High-Speed Precision Lathe Machine

The main parts of a high speed precision lathe machine are the bed and the spindle. The bed forms the base of the machine and the spindle is connected to the bed via a belt drive. The spindle has an axis parallel to the bed and is usually hollow. Its nose and tail contain work-holding arrangements. The tail may have a mechanism on the outboard end for an accessory.

These lathe machines are designed to perform a variety of tasks. During the Industrial Revolution, steam and water wheels were attached to lathe machines. These new features increased their speed and efficiency and made the work much easier. In addition, new designs allowed them to achieve greater precision in their work. In addition to these features, these machines are also used in mass production. However, a semi-skilled worker can also use a CNC lathe machine.

High-Speed Precision Lathe Machine Cost

If you’re looking for a high speed precision lathe machine for your business, you’ll find that you’ll find a wide range of models to choose from. While they are generally efficient for bulk production, some are designed for medium or heavy-duty operations. If you’relooking for a high-volume machine that can take on the toughest shaping jobs, consider the heavy-duty model. Its sturdy machine model and optimal performance are perfect for large-scale operations.

There are many reasons for purchasing a high-quality lathe machine. First, they provide a superior level of precision and accuracy. Second, they are built to be incredibly durable, meaning you’ll be able to use them for a long time. Third, they’re typically cheaper than comparable models. Buying a high-quality machine will allow you to increase your production output while limiting your downtime.

Specifications of High-Speed Precision Lathe Machine

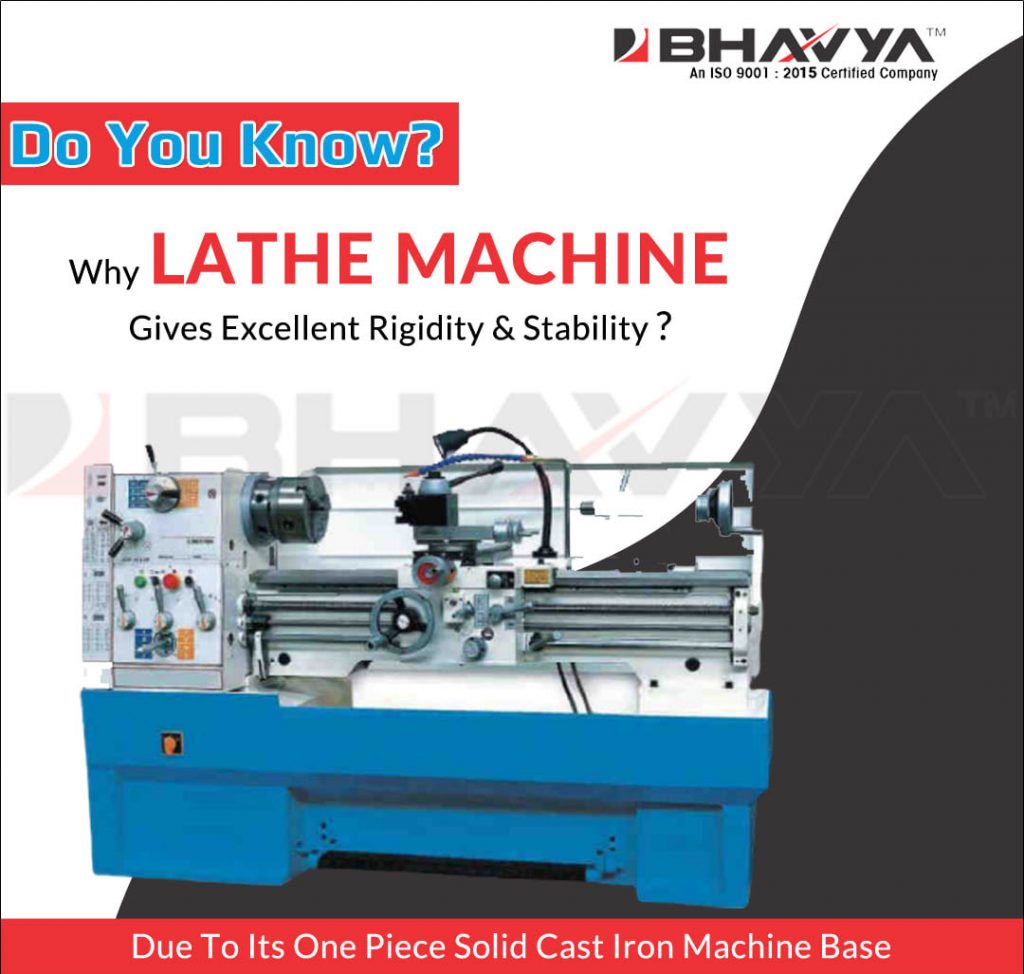

The lathe has two centers: the bed and the headstock. A crossway feeding guide screw is used to feed the workpieces. The high speed precision lathe machine also has a large, one-piece casting machine base with a safety device. It uses a dynamically balanced alloy spindle with bearing support. In addition, its gears are precision ground and hardened.

A high-speed precision lathe machine is an excellent choice for mass production operations. These machines use computer programs to start and stop their operations. Once set up, a semi-skilled operator can operate them. Because they use computer programs to program the machine, they require little training. They are also extremely efficient and accurate and can be operated by a semi-skilled worker after the initial setup.

The Bottom Line

CNC high-speed precision lathe is a CNC vertical turning centre that can process small and medium discs and covers. Its CNC control features full digital optimization and high-speed interpolation for higher machining efficiency. Its compact and durable shape makes it an excellent choice for packaging and mass-production needs. Its multi-axis capabilities are ideal for turning multiple threads, grooves, and other shapes on various materials.