Manufacturing industries dedicated to produce equipments, pharmaceuticals, vehicles, machines, food and beverage and many other components greatly relies on moving raw materials, semi finished products and final products. This is effectively done through materials handling equipments.

Essential features of hydraulic hand pallet truck

This is the most versatile and ubiquitous material handling equipment. The manual forklift uses hydraulic principles to lift materials, transport them and off load them by disengaging the hydraulic mechanism.

Hydraulic Hand Pallet Truck equipment comprises of steering wheel mounted on handle that can turn through 50- 180 degrees to turn the fork lift clockwise or anticlockwise. By cranking the handle up and down, the hydraulic fluid is pumped into the jack they by lifting the materials. It is capable of transporting materials weighing up to 5000kg.

The front and rear wheels are made from reliable materials such as special rubber, nylon of polystyrene. The forks penetrate the pallet boards to hold and secure the merchandise when lifting and transporting. Their width and length can be adjusted to handle different pallet sizes.

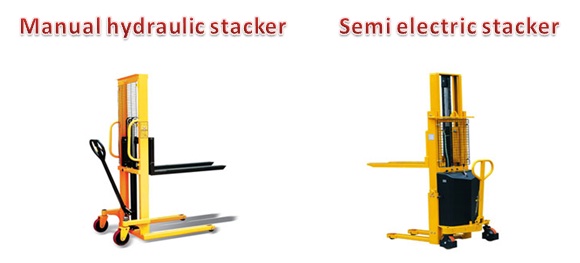

Hydraulic & Semi Electric stacker series

These equipments are improvement of the manual pallet fork lift equipments. They are used for lifting, loading, moving and unloading materials. Unlike forklifts, stackers lift materials, transport, packaging and stack them. Hydraulic and Semi Electric stacker series are easy to handle, use less space, are more sturdy and have increased functionality. The manual model uses the hydraulic action where the operator pumps hydraulic fluid using the reciprocating movement of the handle. The electrical type uses a motor to pump hydraulic fluid for lifting materials. They lift materials to different heights ranging from 1600 mm, 2000mm, 4000mm depending on the model.

Features and uses of high lift trucks

These are specially designed to High Lift Pallet Truck heavy merchandise to high height. Instead of having flat forks to hold the pallets, they have a set of scissor bars for extra load support. They make heavy loads easy to lift to high heights.

Advantages of drum handling equipments

These are specially designed equipment to move round shaped materials. They move drums, buckets and circular objects which cannot be clamped, held easily or loaded onto the pallet. Their main advantages are; they reduce the work associated with camping; they eliminate the need to load and clamp a drum onto the pallet board, prevent spillages and accidental falling of drums when moving, as well as make lifting and moving circular objects easy.

Advance features of scissor lift tables

Scissor lift tables are designed to handle heavy load securely and move it to the required position. They are also used as portable workstations and can safely lift a number of worker and their equipment to high heights.

Their design allows them to handle very heavy loads and move them to the required distance. The table is made to high strength steel capable of withstanding high loading. Their scissor legs are arranged to withstand high loading as well as allow raising and lowering of table. Opening the scissor legs lowers the table while closing the legs raises the table. The equipment is installed with special hydraulic check valves to ensure that once the table is raised, it cannot be lowered unless the operator releases the hydraulic fluid. This prevents accidents of unintended lowering during power failure. . .

Using materials handling equipment to improve throughput

Movement of materials must be done effectively to increase safety, reduce transportation time and increase worker ergonomics. When using the right handling equipments, materials can be moved at ease and this process wastes no time and increases production throughput.