Why a change in Geometry is required?

Manufacturing of metal components involves application of metals as raw materials. When it comes to producing structural gadgets, a lot has to be done with work materials. Therefore, change in geometry of raw materials is highly required to obtain the precise shape or structure. The basic components that are received in the form of sheets or plates are deformed into the desired shape and there stays the change in geometry.

Process planning

Process planning is the listing out of shaping works in accordance with the desired model that is required for producing final product. The actual process of deforming or de-shaping starts from here. The bending is required for industrial applications including steel almirah making, creation of bus structure, electric panel board, etc

Deformation-A vital process in manufacturing sectors

Deformation is considered as the fundamentals of deforming segment. It is changing the shape of work material is followed in several industries including automobiles, aerospace, machine manufacturing, and many more. Metals remain the basic requirement as that provides the required strength to the product structure and manufacturing sectors prefer distortion of materials for other reasons also. Some of them are discussed below.

Enhancing thickness

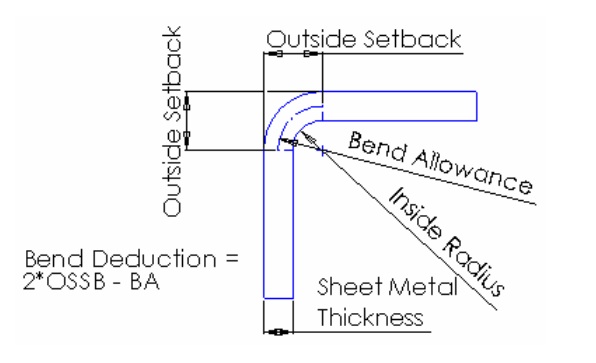

The process of winding sheets was done manually, of course with the support of simple tools. This method is followed to cultivate the pre-planned shape or angle of bend required to make the desired manufacture. It helps to increase the rigidness of the sheet at the winding angle. Application of suitable tools like sheet bending machine can be employed at this stage to receive good resistance to meandering moments without causing damages to the work piece.

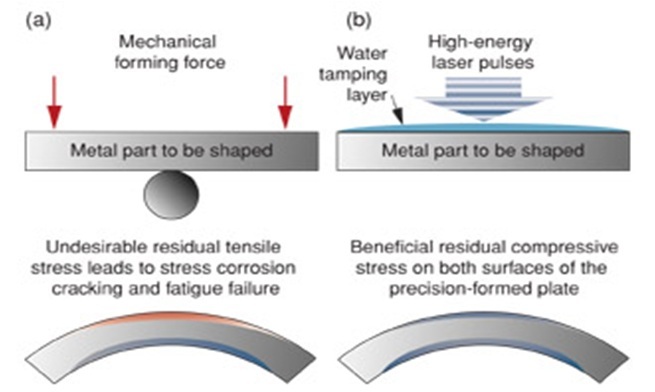

Increase heat indulgence capacity in work material

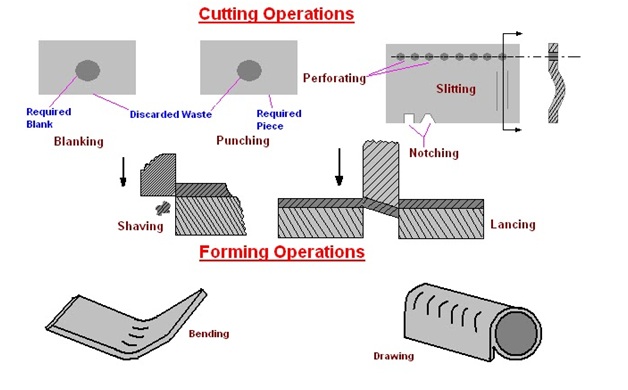

In some cases, heat indulgence capacity of worm material sheets may have to be increased for manufacturing purpose. During such requirements special kind of meandering called lancing can be applied as it helps to enhance heat indulgence or dissipation. This can be followed for multiple processes such as bending as well as cutting.

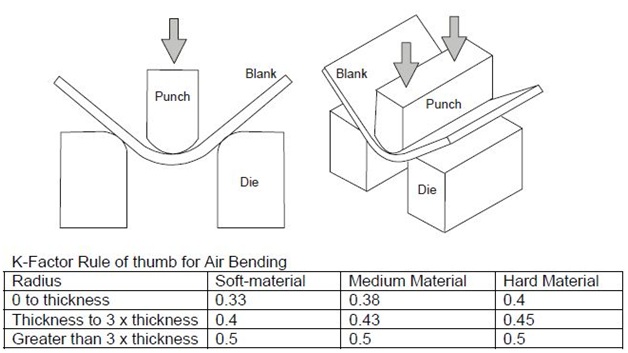

Application of tools to avoid material collapse

There are special ranges of tools like dies that can be incorporated with the existing machinery to obtain specific circuitous angle. These tools help to prevent material collapse as they are specially designed in accordance with the suitability of work material.

Reduce Setup and tool changes

Using complete machinery for deforming process is another way of reducing tool setup or tool change time as these two processed had been in usage since earlier times and they took more time for production.

Decreases Spring Back

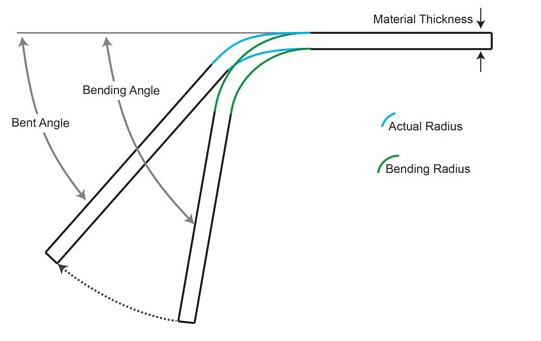

Work materials in the form of sheets are available in different types. There are possibilities of sheets getting spring back at the time of twisting. Therefore using higher end equipment like sheet winding device can help to reduce spring backs.

Metal plate deforming equipment is a versatile kind of device that is featured with suitable features. This machine reduces the need for tool selection as the specifications have been destined for multipurpose usage and above all provides dimensional accuracy. These reasons favor manufacturing sectors to follow bending process.