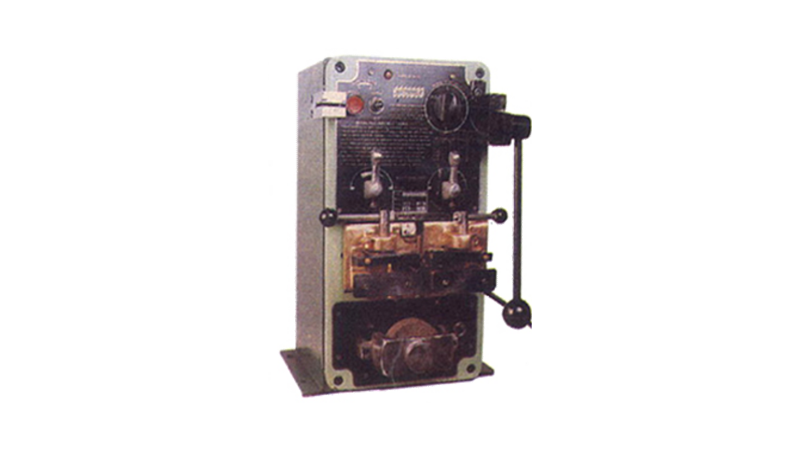

BUTT Welding Machine

Butt-welding is a technique of joining parallel metal plates without any overlap. This is done using the butt-welding machine. The process involves heating the two adjacent plates and joining them under certain amount of pressure. This machine is very economical and reliable since it runs continuously without stop over’s during the production process. The butt-welding machine also does the joining without adding any supply of metals. A hammer is then used to remove the waste material produced.

ARC Welding Machine

The Arc welding machine uses electricity generated by the welding power supply. The machine then creates an electric arch. The heat created by this machine is usually enough to melt the metals. When the metals cool, they then bind together. The arc welding machine first came about around the 19th century and today it is commonly used within the steel and vehicle industries.

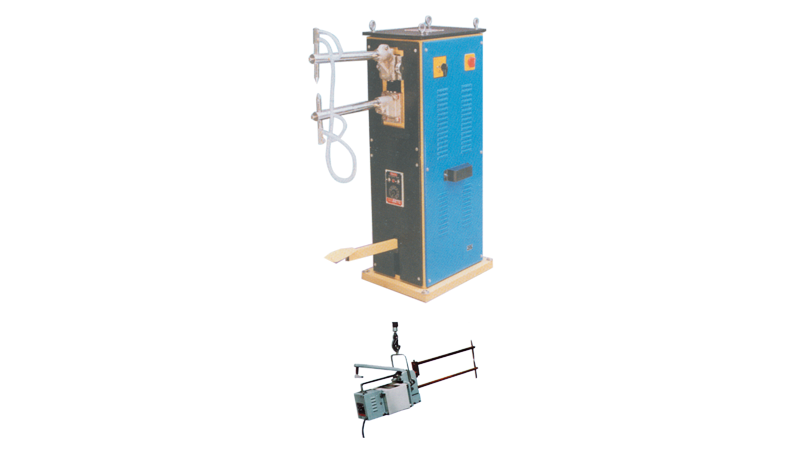

SPOT Welding Machine

The spot welding machine works in such a way that the metal surfaces being worked on are usually put together using the heat that is generated from the resistance to the electric currents. The energy generated will be directly proportional to how large the current is and how long it will take. The spot welding machine is mostly used in the manufacturing industry, in the orthodontics’ clinics as well as making of batteries.

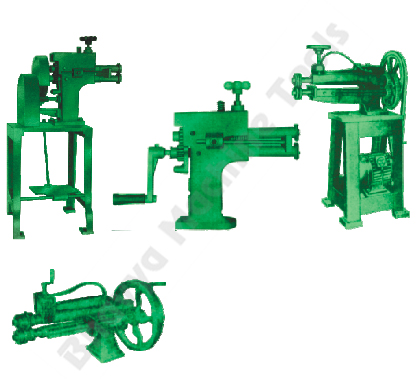

Swaging Machine

The swaging machine uses dies that are placed onto the machine then rotated by a motor. Usually, this machine is very common with the blacksmiths. The swaging machine forms metals into many different shapes that would be hard to form if a hammer alone had been use. The machine also comes in handy when putting together fittings to pipes and cables.

DC Rectifier

This electrical device usually turns alternating current to direct current so that it can flow in one particular direction. DC Rectifier can be in the form of vacuum tube notches or other silicon based semi conductor switches. The rectifier has broad range of uses , mostly on devices that will never run on the alternating current. They provide equally high power output and ha lesser power losses during transmission.

Planer Machine

This machine is almost like a shaper but it is larger in size. The Planer Machine makes use of linear movement between the piece being worked on and the cutting tool to cut the piece. In most scenarios, the machine provides flat surfaces that are in a way more precise as grinding. It is also used to generate slots for keys. Currently, this machine has undergone various technological advancements to avoid being replaced by the drill bit grinder, folding machine and mini-milling machines.

HOSE Crimping Machine

This machine is mostly suitable for operation in the rubber industry. Hose Crimping Machine is suitable for pressing tubes such as pipes that have substances flowing in high pressure. This machine is mostly used in the mechanical engineering industries to pass on hydraulic pressure.

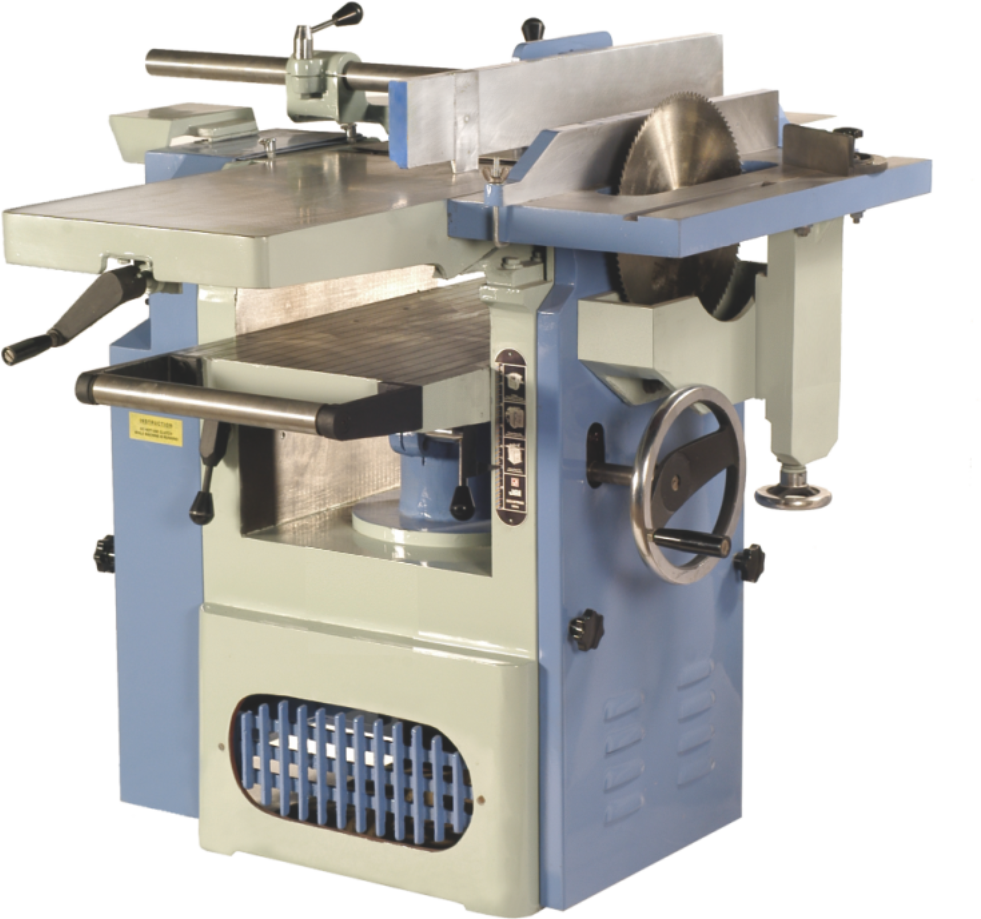

Mortising Machine

Mortising machine usually makes the waste get out in one simple operation. It operates in a better way than the chisel or router. It has better speed, has better quality and is more efficient.