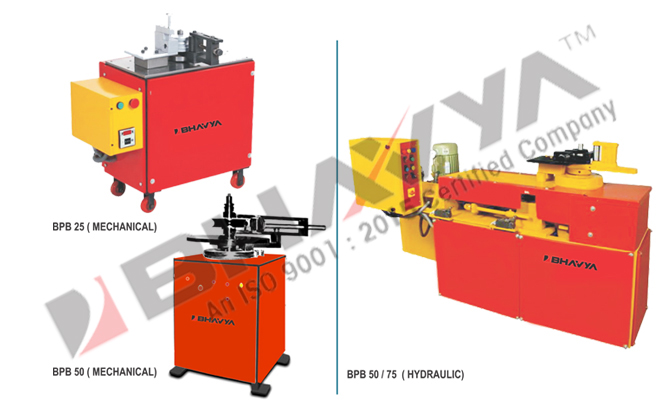

There are a number of factors to consider when purchasing a Steel Pipe Bending Machine. Specifically, its output capacity, or the number of parts per hour produced, is of critical importance. This will vary depending on the type of tube, its size and shape, and the experience and proficiency of the operator. To make an informed choice, it is best to speak with the manufacturer of the machine to learn more about its specifications. One of the leading manufacturers of pipe bending machines is Bhavya Machine Tools.

Compression Bending Vs Roll Bending

The two basic types of pipe bending are roll bending and compression bending. Both methods require different types of tooling. A roll bending machine requires a clamp die, whereas a compression bender does not. Clamp dies hold the tube while it is being bent. Pressure dies are designed to prevent the part from kicking out during the bending process.

In roll bending, the tube is pressed against a triangular set of pivot blocks and is pushed to a certain bend radius. This method is the least complex, but cannot be controlled as precisely as other methods. This method is frequently used to bend large construction pieces. In addition to tube bending, it can produce spirals and continuous coils.

Tube Bending Machines

Tube bending machines are used to shape different types of tubes. The process of bending involves changing the thickness of the tube’s walls at the radiuses. The inner wall becomes thicker while the outer wall becomes thinner. This process results in different types of wrinkles on the tube’s walls depending on the angle and thickness of the bend.

Standard tube bending machines come with length setting, a pressure die cylinder, and an operator control. The operator can enter the desired pressure die length, and the machine automatically performs the cycle movements required. In addition, the pressure die cylinder adjusts automatically as the tube’s dimensions change. These advanced machines also feature compact design to reduce material waste at the end of a bend.

Free-form Bending Process

Free-form bending is a process that involves the movement of a movable die and allows for a large degree of freedom during the process. This type of bending allows for the development of bending strategies that allow for different residual stresses and geometry pairs.

Free-form bending on pipe bending machinery involves the movement of a movable die in a single plane. The movement of the die in a single plane depends on the diameter and the hardness of the material. This type of bending is also called non-tangential bending. The minimum and maximum pressures of the bending process are displayed in a schematic model.

Bending Stainless Steel Pipes

Pipe bending machines are used to bend various kinds of pipes into various shapes. They are commonly used for round and rectangular pipes made of stainless steel and other thin-walled metals. These machines are easy to use. They are equipped with several dies to make bending easier. Each die can be used to make a different kind of bend.

The bending process consists of a series of stages, each resulting in a different cross-sectional shape. The first step involves determining the radii and angles of the metal tube. Then, the second step involves determining the number of ball joints required, which will depend on the cross-sectional shape of the tube. The smaller the ball joint number, the smaller the radius of deformation.

Need for Pipe Bending Machines

Pipes for freshwater systems, hydraulic systems, and diesel fuel distribution may need to be bent with tight radius. The precision of these bends is required to be millimetre-perfect. In the past, all pipes were fabricated sectionally and welded together to make a final assembly. Every weld was inspected and cleaned. Non-destructive x-ray testing was also required to ensure that the welds were welded properly. A bending machine eliminates these steps and allows the operator to focus on the final job – bending the pipes to the desired length.

The bending process can also be automated. There are several types of pipe bending machines that can perform a variety of different shapes. Some of these pipe bending machines use a hydraulic drive, pneumatic drive, or manual drive to bend the pipes. These machines also have a clamping block that holds the pipe to the die. A pressure die is used to bend a pipe with a curved profile. Mandrels are also used for bending pipes with small radii.

Pipe Bending Machine Can Bend Different Metals

A pipe bending machine is used for bending various metal materials. The metals used are typically ductile and have small elasticity. The pipe bending machine creates a smooth curve by bending these metals. A pipe is a hollow container used for transporting liquid, gas, or solid materials. The bending machine is most commonly used for laying pipes. It consists of several parts: the clamping die, bend die, pressure die, wiper die, and mandrel. The clamping die is usually made of hardened steel to prevent damage.

Pipe bending machines are used in numerous industries including aerospace and automobile. Exhaust and radiator pipes are among the most common applications. Generally, pipe bending machines are CNC-controlled machines. These machines are also used in seat frames, headrests, and hood struts of cars. They are also used in iron, steel, and aluminum furniture.

The Bottom Line

Pipe bending machines are designed to bend pipes and tubes into various shapes. They can be used for both simple and complicated operations. They can also be used for the production of ladder rungs. These machines are designed with several advanced features. Some of these features include a tube loader, servo-electric pick & place system, ejection chute, and pipe separation device.

The servo motors used in the machine help the operator to adjust the bending angle. This feature allows the pipe bender to achieve precise control. The machine is also highly versatile and powerful. It can perform the bending process of different types of pipe materials, including round and square tubes.