Kenya’s agricultural sector is a key driver of the economy, supporting millions of livelihoods. The demand for locally manufactured farming tools and machinery is increasing as farmers seek more efficient equipment. Lathe machines play a crucial role in producing durable and precise components for plows, tractors, irrigation systems and harvesting tools.

Significance of Lathe Machines in Agricultural Equipment Manufacturing

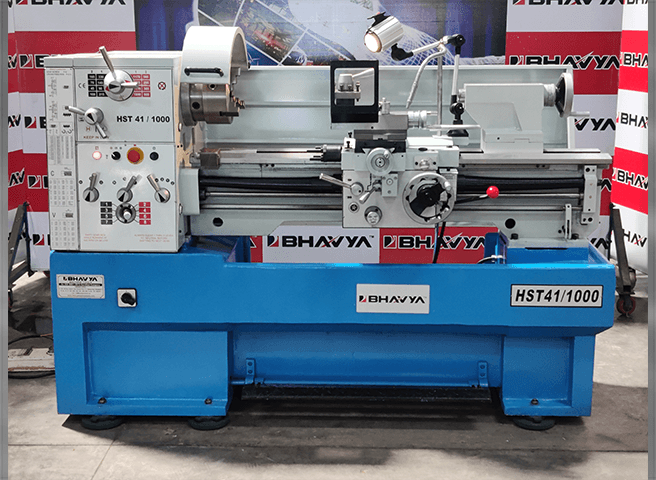

Manufacturing agricultural tools requires precision, durability and efficiency. Light Duty Lathe machines help shape metal components, ensuring high-quality products.

Key Applications in Agricultural Equipment Production:

- Machining tractor parts such as axles, shafts and engine components.

- Manufacturing plow blades and other tillage tools.

- Producing irrigation system fittings with precise threading.

- Repairing worn-out machine parts to extend their lifespan.

Impact in Different Cities:

- Nairobi: As Kenya’s industrial hub, Nairobi is a major producer of high-quality farming equipment.

- Eldoret: Known for agricultural activities, this city benefits from local manufacturing of essential farm machinery.

- Thika: Home to several engineering firms specializing in Vertical lathe machines for agricultural tools.

Lathe Machines: Enhancing Precision and Efficiency in Equipment Manufacturing

Precision machining ensures that farm tools and machinery perform reliably under tough conditions. Geared Lathe machines contribute by shaping metal with accuracy, reducing material waste and improving productivity.

How do Lathe Machines Improve Manufacturing?

- Produce uniform components that fit seamlessly in larger equipment.

- Allow faster production rates for mass-market farming tools.

- Reduce costs by enabling local manufacturing instead of relying on imports.

Regional Adoption Trends:

- Eldoret: High demand for precision-machined spare parts for tractors and harvesters.

- Thika: Local businesses focus on efficiency, producing irrigation components.

- Mombasa: Workshops refine machine parts for agricultural exports to neighboring regions.

Role of Lathe Machines in Heavy Agricultural Machinery

Large-scale farming requires heavy machinery, which relies on strong, well-machined components. Vertical lathe machines are essential for handling large parts that require precision shaping.

Key Applications of Vertical Lathe Machines:

- Machining flywheels and crankshafts for tractors.

- Producing large irrigation pumps and water distribution system parts.

- Shaping steel components for heavy-duty harvesters and plowing machines.

City-Specific Impact:

- Nairobi: Major engineering firms use vertical lathes to produce tractor and plow components.

- Kisumu: Small businesses adopt vertical lathes for water pump and irrigation system manufacturing.

- Eldoret: Increased investment in universal all geared lathe machines to support mechanized farming operations.

Challenges in Adopting Lathe Machines for Agricultural Equipment Production

Despite their advantages, the adoption of lathe machines in Kenya faces some challenges.

Key Barriers:

- High acquisition costs for advanced lathe machines.

- Limited access to skilled machinists for operating and maintaining the equipment.

- Dependence on imported spare parts, leading to delays and increased costs.

- Inconsistent power supply affecting machine operation in some regions.

City-Specific Challenges:

- Nairobi: High cost of modern Turret Lathe Machines restricts access for small workshops.

- Kisumu: Limited technical training centers slow the adoption of advanced machining techniques.

- Mombasa: Dependence on imported lathe machines increases production costs.

Future of Lathe Machines in Kenya’s Agricultural Equipment Industry

The demand for modern agricultural machinery is expected to grow as Kenya expands its mechanized farming sector. Investment in lathe machine technology may improve local production capabilities.

Trends and Opportunities:

- Increased use of Automatic CNC Lathe Machine, technology for precision manufacturing.

- Development of training programs to equip machinists with advanced skills.

- Expansion of manufacturing hubs in secondary cities to decentralize production.

- Government incentives to encourage local production and reduce reliance on imports.

Regional Growth Potential:

- Nakuru: Emerging as a key manufacturing center for advanced agricultural machinery.

- Thika: Expansion of machine tool workshops to support small-scale farmers.

- Eldoret: Increasing investments in industrial machining for high-capacity farming tools.

Conclusion

Lathe machines are playing a transformative role in Kenya’s agricultural equipment industry. They help local manufacturers produce high-quality, durable and efficient farming tools, reducing reliance on imports. Cities like Nairobi, Mombasa and Eldoret are at the forefront of this shift, with increased investment in geared and vertical lathe machines.

Despite challenges such as high costs and limited technical expertise, the future looks promising. With improvements in training, infrastructure and technology adoption, Kenya may strengthen its position as a leading producer of agricultural machinery in the region.