Flexible Arm Tapping Machine is a tool that is used for making thread holes on a surface. It has an articulated arm that is adjustable. The machine can drill holes in steel or aluminium. It can save time and material.

What is a Flexible Arm Tapping Machine?

A flexible arm tapping machine, also called a flex arm tapper, is a handy tool that can be used for repetitive tasks. Its ergonomic design helps protect workers from repetitive stress injuries. It comes with tap holders in different sizes and is compatible with an optional work cart.

Featuring an automatic tapping process, this machine can process a variety of materials. The high-precision servo motor is designed to provide smooth and accurate tapping. The machine’s body is also stable, so it reduces shaking during work. It can process metal, plastic, and aluminum parts and is popular in mold and woodworking industries.

The tapping arm is another excellent machine for repetitive tasks. It has an ergonomic design that minimizes fatigue and maximizes worker productivity. It also allows for 90-degree tapping. And, the machine’s weight is counterbalanced by a counterweight, so it is easier to manoeuvre around the work area.

The machine taps at a variable speed and features an environmentally friendly, energy-saving motor. Suitable for general use, it’s easy to operate and requires no professional training.

Flexible Arm Tapping Machine Saves Money, Time, and Materials

The Flexible Arm Tapping Machine is a powerful tool for precision tapping. It guarantees accuracy and repeatability. Its servo motor and stable body minimize vibration and shaking during work. It is useful for taping aluminium, steel, plastic, and other metal materials.

The Electric tapper saves money, time, and materials because the machine handles all of the prep work. This reduces material handling time in the mill and eliminates the need for human labor. The tapping machine also features a torque clutch that automatically stops the tapping process when an obstruction is encountered. This eliminates mental fatigue, which is important for small taps.

Using a flexible arm tapping machine reduces labour costs by up to 50 percent. This machine also helps manufacturers reduce scrap by 90%, since it eliminates repetitive positioning errors. It also reduces the need for expensive jigs and fixtures. A flexible arm tapping machine can also be used for drilling.

Flexible Arm Tapping Machines are a better alternative to a standard drill press, since they allow users to move the tapping operation from one place to another. Mobile tapping machines feature pneumatic tapping arms with a 360-degree rotation. These machines are lightweight and do not require a qualified machinist to operate.

The Tapping Machine includes a high-quality hydraulic motor, quick-change chuck, and direction control switches. Its arms can cover a large area, ensuring consistent accuracy at every corner. The arm also features a unique level of flexibility that allows the operator to perform tap operations without any special operating knowledge.

Flexible Arm Tapping Machines also eliminate repetitive tasks and increase productivity by cutting materials faster and more accurately. These machines save time, materials, and energy. They are easy to use and are very flexible.

Flexible Arm Tapping is Used for Making Thread Holes on a Surface

A Flexible Arm Tapping Machine is a machine used to make thread holes on a surface. This machine eliminates the need for a compressor and is able to accurately deliver energy without the use of pneumatic piping. In addition, it can be moved to various locations and uses minimal amount of electricity. It also has a depth control facility. The machine is a cost-effective option as it requires less electric power than its CNC counterpart.

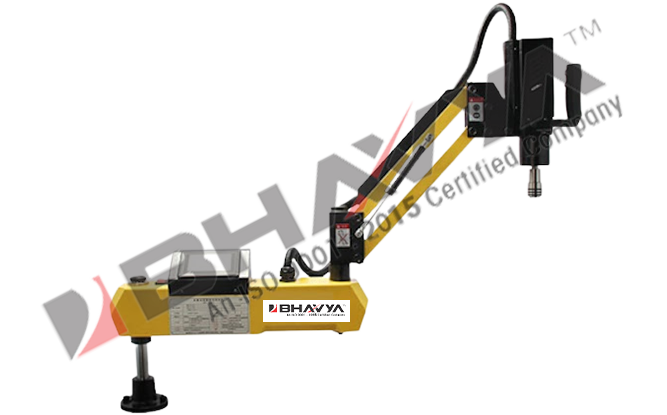

The Flexible Arm Tapping Machine is a powerful machine that can be used for making thread holes on a variety of surfaces. It is available at affordable prices and is made from top graded components and exceptional technology. There are several types of these machines available in the market. One of the best manufacturers of this machine is Bhavya Machine Tools, located in Ahmedabad, Gujarat, which offers a wide range of flex arm tapping machines.

The Flex Arm Tapping Machine uses a rotating tap with an articulated arm to make thread holes on a surface. It is a versatile machine that can be used on various workstations.

A flexible arm tapping machine has a working motion, which means that it can be adjusted to fit a variety of products. The arm can also be configured to move upward or downward depending on the type of product. In addition, the arm can be fully positioned in the horizontal or angled position. A flexible arm tapping machine is an ideal tool for machining large and small threads.

A Flexible Arm Tapping Machine can also be used for blind holes. The blind hole will not be completely threaded through the surface, instead it will be a single-sided hole. A through-hole is a threaded hole on both sides of a surface. It is also possible to make a thread on both sides of a surface, and it is called a threaded hole.

The Flexible Arm Tapping Machine can be configured in three modes: tapping, blind tapping, and radial tapping. Each mode has its advantages and disadvantages. It has a limit switch on the panel to prevent blinding.

In Conclusion

A tapping machine is one of the most efficient ways to perform tapping operations. It offers flexible arm movements and counterbalances the weight of the machine, thereby reducing fatigue. The flexible arm also features a universal head that allows the operator to tap holes with either an angular or horizontal orientation.