Elevators and escalators are essential components of modern infrastructure. The demand for high precision, durability, and efficiency in their production has never been higher. Fiber laser cutting machines have emerged as a game-changer in the fabrication process, ensuring superior accuracy, speed, and cost-efficiency. This article explores how fiber laser cutting technology enhances the manufacturing of elevators and escalators.

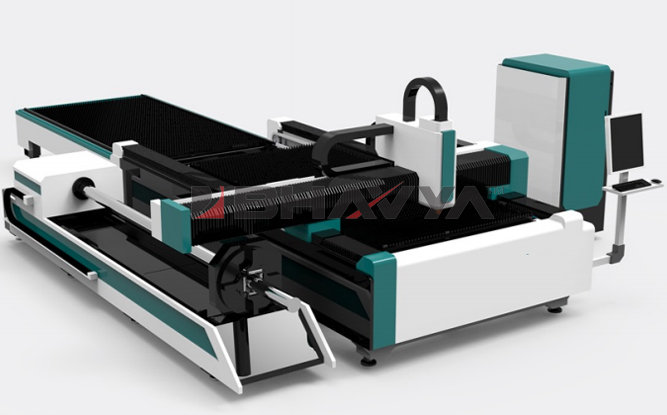

What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine is an advanced tool that uses high-powered laser beams to cut through metals with extreme precision. Unlike traditional cutting methods, fiber lasers offer:

- Higher cutting speeds

- Greater energy efficiency

- Minimal material wastage

- Smooth and clean cuts without burrs

How Fiber Laser Cutting Works?

This machine directs a concentrated laser beam onto the metal surface, generating heat that melts or vaporizes the material. The process is aided by a high-pressure gas (such as nitrogen or oxygen), ensuring a precise and clean cut.

Key Materials Used in Elevator & Escalator Fabrication

Elevators and escalators require high-strength, corrosion-resistant materials for safety and durability. The most commonly used metals include:

- Stainless Steel – For interior panels, railings, and decorative elements.

- Carbon Steel – Used in structural components due to its strength.

- Aluminum – Lightweight yet strong, often used in escalator steps.

- Galvanized Steel – Provides rust resistance for long-term durability.

Why Fiber Laser Cutting is Ideal for These Materials

Fiber lasers provide exceptional accuracy and flexibility, making them ideal for cutting a wide range of metals. Their ability to handle thin to thick materials without compromising quality makes them the preferred choice in the industry.

Benefits of Fiber Laser Cutting Machines in Elevator & Escalator Production

Extreme Precision & Accuracy

Fiber lasers can achieve cutting tolerances as small as ±0.05 mm, making them perfect for intricate elevator panel designs, support structures, and control enclosures.

High-Speed Processing for Increased Productivity

Compared to traditional methods, fiber lasers cut 2-3 times faster. This significantly speeds up production, reducing lead times and improving efficiency.

Cost-Effective Manufacturing

- Lower material waste due to precise cutting

- Minimal maintenance compared to CO₂ lasers

- Reduced labor costs with automation integration

Seamless Edge Quality

Unlike mechanical cutting tools, fiber lasers produce clean edges with no secondary finishing required. This is critical for aesthetic elevator interiors and safety-critical escalator steps.

Advanced Automation & CNC Control

Modern CNC-controlled fiber lasers allow manufacturers to automate the cutting process, reducing human error and improving repeatability. This ensures uniformity in mass production.

Applications of Fiber Laser Cutting in Elevator & Escalator Manufacturing

Elevator Car Frames & Doors

Precision cutting ensures perfectly aligned elevator doors and car frames, which is crucial for safety and operation.

Decorative Panels & Control Interfaces

Many modern elevators feature intricate designs and laser-cut stainless steel panels for aesthetic appeal. Fiber lasers enable detailed engraving and custom patterns.

Escalator Steps & Handrails

Escalator steps require exact measurements for proper fit and function. Fiber lasers cut these components with unmatched accuracy, ensuring smooth assembly.

Structural Beams & Support Frameworks

Strong, well-cut beams are essential for the structural integrity of elevators and escalators. Fiber lasers provide clean and strong weld-ready cuts, reducing the need for additional processing.

Comparing Fiber Laser Cutting with Traditional Cutting Methods

| Feature | Fiber Laser Cutting | CO₂ Laser Cutting | Plasma Cutting | Water Jet Cutting |

| Cutting Speed | Very High | Moderate | High | Low |

| Precision | Excellent | Good | Moderate | Excellent |

| Material Waste | Low | High | Moderate | High |

| Maintenance Cost | Low | High | Moderate | High |

| Energy Efficiency | High | Low | Low | Low |

From the table, it’s evident that fiber laser cutting surpasses other methods in terms of speed, precision, and cost-effectiveness.

Future of Fiber Laser Cutting in Elevator & Escalator Manufacturing

As laser technology advances, we can expect:

- Higher power fiber lasers for even faster cutting.

- AI-integrated systems to optimize cutting patterns and reduce waste.

- More automation in production lines for increased efficiency.

Key Takeaways & Insights

- Fiber laser cutting machines provide unmatched precision, speed, and efficiency in elevator and escalator fabrication.

- They work on stainless steel, carbon steel, aluminum, and galvanized steel, ensuring high-quality output.

- Automated CNC fiber lasers enhance productivity, reduce material waste, and lower manufacturing costs.

- Compared to traditional methods, fiber laser cutting offers cleaner cuts, lower maintenance, and higher efficiency.

- The future of fiber laser technology in the industry is geared towards AI-driven automation and enhanced performance.