All Geared Lathe Machines have revolutionized the machining industry, offering versatility and precision. In this article, we delve into the various types and applications of these machines, shedding light on their significance in modern manufacturing.

Understanding All Geared Lathe Machines

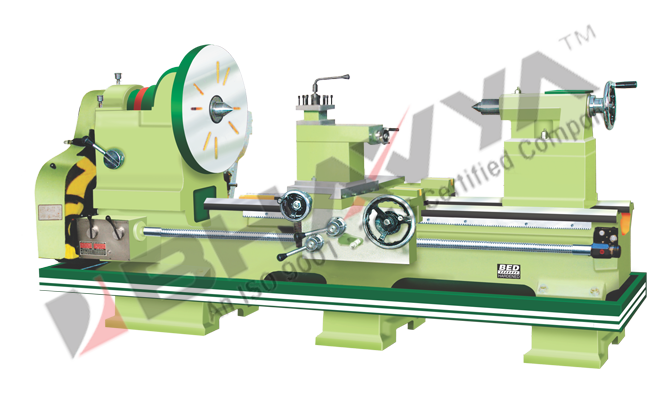

Before we explore the specific types, let’s understand the fundamental concept of All Geared Lathe Machines. These devices use gears to control the speed and movement of the workpiece, providing enhanced accuracy and efficiency.

Light Duty Lathe & Medium Duty All Geared Lathe Machine

Designed for smaller projects, light-duty and medium-duty All Geared Lathe Machines are perfect for workshops with diverse machining needs. They offer a balance between precision and flexibility, making them ideal for various applications.

The Robust Heavy Duty Lathe Machine

When it comes to handling substantial workpieces, the Heavy Duty Lathe Machine takes center stage. Its robust build and powerful capabilities make it indispensable for large-scale manufacturing.

Exploring the Vertical Drive Lathe Machine

Vertical Drive Lathe Machines bring a vertical orientation to the machining process, offering unique advantages such as improved chip evacuation and reduced tool wear. This section delves into their features and applications.

Precision in Motion: Slant Bed CNC Lathe Machine

Integrating computer numerical control (CNC), the Slant Bed CNC Lathe Machine ensures unparalleled precision. From complex contours to intricate designs, this machine opens up new possibilities in machining.

Turret Lathe Machine: A Versatile Tool

Versatility defines the Turret Lathe Machine, equipped with a turret holding multiple tools. This section explores how this design facilitates quick tool changes, improving efficiency and reducing downtime.

Applications Across Industries

All Geared Lathe Machines find applications across diverse industries, including automotive, aerospace, and medical. Each type serves specific purposes, contributing to the efficiency of manufacturing processes.

Choosing the Right All Geared Lathe Machine

Selecting the appropriate machine for your needs is crucial. Factors such as the size of workpieces, material requirements, and desired precision play a vital role. This section provides insights into making an informed decision.

Maintenance Tips for Longevity

To ensure the longevity of All Geared Lathe Machines, proper maintenance is essential. From routine inspections to lubrication, this section offers practical tips to keep your machine in optimal condition.

Advancements in Lathe Machine Technology

The world of machining is dynamic, with constant advancements. Explore the latest technologies incorporated into All Geared Lathe Machines and how they contribute to increased efficiency and precision.

Future Trends

What does the future hold for All Geared Lathe Machines? This section discusses emerging trends and innovations, giving readers a glimpse into the evolving landscape of machining technology.

Investing in Quality: Brands and Considerations

When investing in an All Geared Lathe Machine, choosing a reputable brand is crucial. This section highlights leading brands and essential considerations to ensure a wise investment.

Conclusion

In conclusion, All Geared Lathe Machines have become indispensable in the manufacturing sector, offering a wide range of options for various applications. From light-duty to heavy-duty, vertical drive to CNC, these machines continue to shape the future of machining technology.

FAQs About All Geared Lathe Machine

Q1: Can All Geared Lathe Machines handle small-scale projects?

Yes, there are specific models designed for light-duty and medium-duty applications, making them suitable for smaller projects.

Q2: What maintenance is required for All Geared Lathe Machines?

Regular inspections, lubrication, and proper cleaning are essential for maintaining the longevity and efficiency of these machines.

Q3: Are All Geared Lathe Machines suitable for aerospace applications?

Yes, certain types of All Geared Lathe Machines are designed to meet the precision requirements of aerospace manufacturing.

Q4: How do advancements in technology impact the performance of these machines?

Technological advancements contribute to increased efficiency, precision, and versatility in All Geared Lathe Machines, keeping them at the forefront of machining technology.

Q5: Can a Turret Lathe Machine handle rapid tool changes efficiently?

Absolutely. The turret design allows for quick and seamless tool changes, minimizing downtime and enhancing productivity.