Pitfalls in Lathe Operation

Lathe is versatile equipment that works worthwhile for several operations starting from cutting, to turning and deforming. Professional performance brings specific results in productivity because there are ample possibilities of faults to happen while staging a cutting action. The errors vary in mechanism in accordance with the type of materials such as metal or wood. Below are some of the

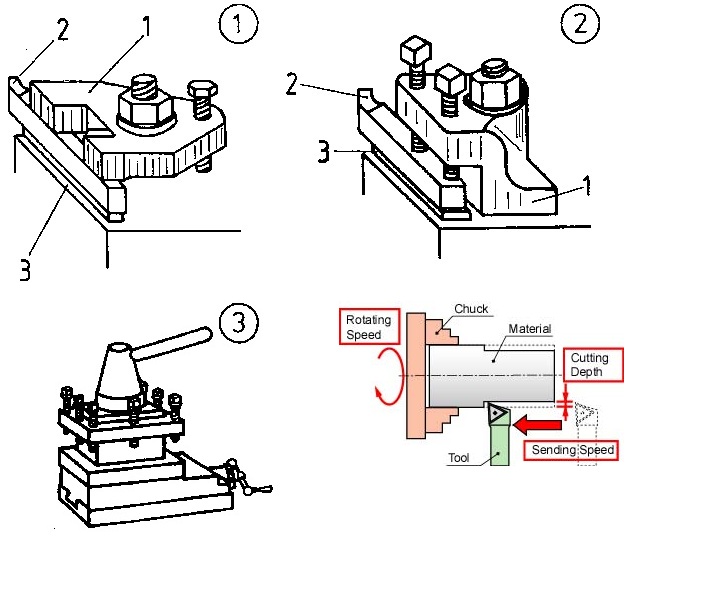

Rotating Speed Adjustment

It is mandatory condition to be checked for before feeding exertion material. Though it may appear a common criterion, it is highly advised to ensure material thickness, tool and speed compatibility to achieve accuracy.

Material Feed Rate

Heavy setting starts to slow down the process and diminish the quality of machining. During such conditions, the headstock gets disengaged before it meets the stop point. Professionals or skilled operators will be able to find out this error. For those who start with heavy settings, it would be better to apply small amount of hand feed and then try out with reversing the carriage and begin the next step. Checking the dial through the help of lock screw is another way to achieve precise metal working

Cutting Depth-Preventing Short Bytes

The depth of engraving goes in tune with toll selecting, pace, metal texture etc. For bigger depth requirement setting with small value of cutting and enhancing later gives better results. Therefore prefer machining with moderate velocity, lower depth and gradual increase of job portion supply.

Improper Tool Arrangement

Fixing the engraving device in an improper position with imbalanced height balance causes damage to dimension of slashing. The recommended pose is fitting at the centre of chuck as this will ensure accuracy of cuts and keep the work stuff free from damages. However, fixing can be done by running the lathe gradually so that the chuck is not fast on rotation.

Sensing Blunders through Noise

With the inception of superior ranges of lathe models like vibration free, high speed, etc the point of finding mistakes is possible if only the equipment is managed by inexperienced operator or wrong substance feed position. However, there is a smart hint for the inexperienced to tactically grasp wounding mishaps is from high sound created during processing. If there is too much rotation speed or vibration the sound differs and this could help the operator to guess processing drawbacks.

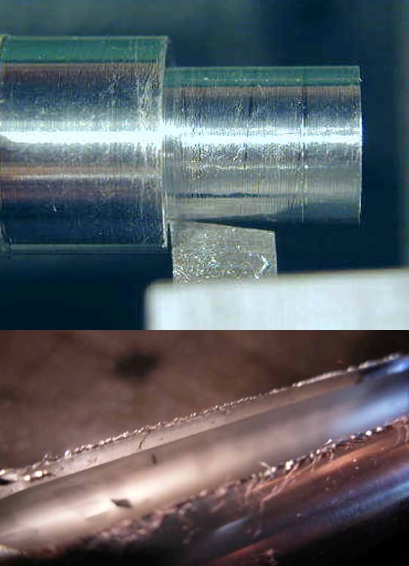

Things to confirm before Turning

Turning is of different varieties such as facing off, tapering, facing to the length, boring, etc. The mechanism also differs wherein, the work object rotates and the instrument is fed against. Inaccuracies are identified through ensuring discoloring or ragging of job piece. Unmatched texture or surface forming on substance also indicated inappropriate operation. Such happening is likely when tempo or ingredient supply is incorrect.

Conclusion

Any workshop apparatus is designed only by means of reaching perfection and accuracy. However, errors may appear in most cases due to inexperienced trials. For successful results avoiding mistakes from operational aspects can help productivity in multiple ways.