Milling machines are indispensable tools in the manufacturing industry. They come in different types, each designed for specific tasks, ranging from light precision jobs to heavy-duty operations. This article covers different types of milling machines, including Vertical Turret Milling Machines, All-Geared Vertical Milling Machines, Universal Milling Machines and more. Each section will answer common questions about these machines, helping you understand their features, benefits and applications.

Vertical Turret Milling Machine

A Vertical Turret Milling Machine is designed for precise and detailed milling work. It features a vertically oriented spindle that allows for accurate cutting, drilling and boring of parts.

Various Questions and Answers that you would like to know about Vertical Turret Milling Machine:

What is the primary use of a Vertical Turret Milling Machine?

- The Vertical Turret Milling Machine is primarily used for machining smaller parts that require high precision. It’s ideal for industries like mold making, prototyping and small-scale production of mechanical components.

How does the turret feature benefit users?

- The turret allows for a variety of attachments, making the machine versatile. Operators can easily switch between different tools without changing the entire setup, saving time and increasing productivity.

Is a Vertical Turret Milling Machine suitable for mass production?

- While the Vertical Turret Milling Machine is excellent for precision and small batch work, it’s not typically used for high-volume mass production. It’s best suited for small to medium runs or custom jobs.

All-Geared Vertical Milling Machine (EVM1332)

The All-Geared Vertical Milling Machine (EVM1332) is equipped with an all-geared mechanism that provides high torque and consistent performance, making it ideal for a wide range of applications.

FAQs on All-Geared Vertical Milling Machine:

What makes the EVM1332 different from other milling machines?

- The EVM1332 features an all-geared mechanism, ensuring smooth operation with minimal maintenance. This makes it highly reliable and efficient for both light and heavy-duty milling tasks.

Can the EVM1332 handle high-volume milling?

- Yes, this machine is designed to handle medium to high-volume milling operations, especially in environments where stability and reliability are crucial.

Is this all geared vertical milling machine suitable for precision milling?

- The EVM1332 is excellent for precision milling due to its sturdy build and precise controls. It can perform a variety of milling operations with high accuracy, making it suitable for applications in tool-making, automotive and metalworking industries

Light Duty Universal Milling Machine

The Light Duty Universal Milling Machine is a versatile and compact machine designed for precision work in smaller-scale production environments.

FAQs on Light Duty Universal Milling Machine:

What is the capacity of the Light Duty Universal Milling Machine?

- As the name suggests, this machine is designed for light-duty tasks. It is typically used for smaller workpieces and can handle precise milling tasks, but it’s not suitable for heavy-duty operations.

How does light duty universal milling machine compare to heavier models?

- Unlike heavy-duty milling machines, the Light Duty Universal Milling Machine is more compact and less expensive. It offers excellent precision for small parts but lacks the power to handle larger, more complex tasks.

Is this light duty milling machine suitable for beginners?

- Yes, its user-friendly interface and compact size make it an excellent choice for beginners or small shops starting with milling operations.

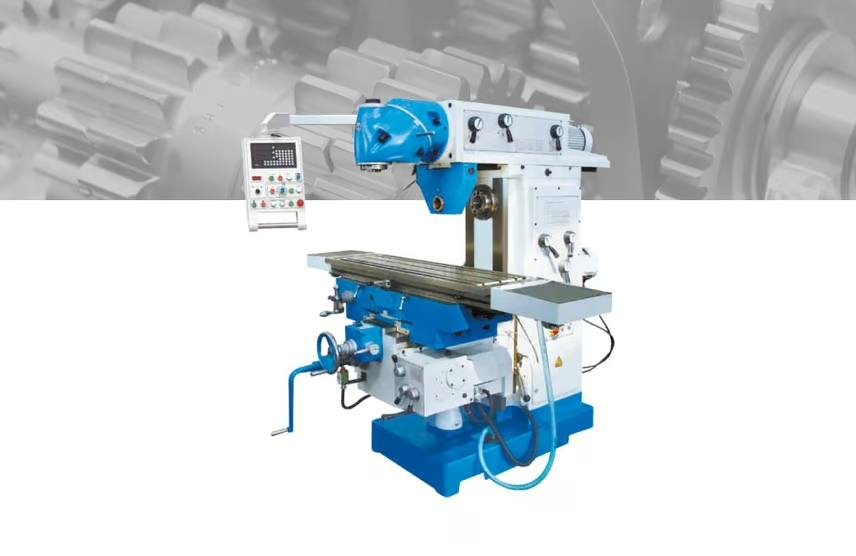

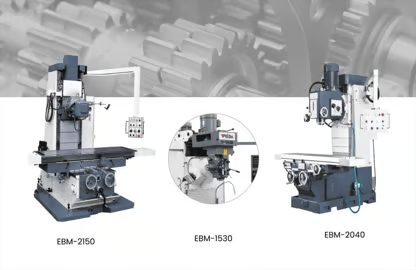

All-Geared Universal Milling Machine ADM

The All-Geared Universal Milling Machine ADM is known for its versatility in handling both horizontal and vertical milling. This machine can tackle a wide variety of tasks, making it an essential tool in many industrial settings.

FAQs on All-Geared Universal Milling Machine ADM:

What are the advantages of the All-Geared Universal Milling Machine ADM?

- The all-geared mechanism offers smoother operation with higher torque, making it ideal for handling large workpieces and complex tasks. Additionally, its universal milling capabilities allow for both vertical and horizontal milling.

Can this all geared milling machine handle both small and large-scale operations?

- Yes, the All-Geared Universal Milling Machine ADM is flexible enough to handle both small and large-scale operations, making it suitable for diverse industries like automotive, aerospace and general manufacturing.

How does the gearing mechanism improve performance?

- The all-geared system ensures that power is efficiently distributed throughout the machine, reducing vibrations and increasing precision. This system enhances both speed and accuracy, making it perfect for demanding tasks.

What Our Customers Say

“Good service. Providing full and real information before delivering the product.I purchased lathe machine and many more products from Bhavya.From Gujrat to Kashmir long distance, with proper packaging received lathe machine 100% in good condition.Worked on machine,The accuracy is too good. Thanks Team Bhavya”

Nasir Hayat On Google

Extra Heavy Duty All Geared Milling Machine

The Extra Heavy Duty All Geared Milling Machine is designed for extreme conditions and heavy-duty operations. It can handle the most challenging materials and large workpieces with ease.

FAQs on Extra Heavy Duty All Geared Milling Machine:

What sets the Extra Heavy Duty All Geared Milling Machine apart from other machines?

- This machine is specifically built to handle heavy-duty operations. Its robust construction and high-torque gearing system make it ideal for machining large and hard materials without compromising performance.

Is this machine suitable for industries with high production demands?

- Absolutely! This machine is designed for high-volume production and heavy-duty work, making it ideal for industries like aerospace, construction and heavy metalworking.

Can this machine operate continuously without overheating?

- Yes, the Extra Heavy Duty All Geared Milling Machine is designed for continuous operation. Its advanced cooling and gearing systems allow it to run for long periods without overheating or losing performance.

Heavy Duty Bed Type Universal Milling Machine

The Heavy Duty Bed Type Universal Milling Machine is designed for large-scale production and precision work on large components. It features a bed design that provides superior stability for heavy milling tasks.

FAQs on Heavy Duty Bed Type Universal Milling Machine:

What makes the bed-type design important in milling machines?

- The bed-type design offers greater stability, especially during heavy milling operations. The machine can handle larger workpieces with minimal vibration, ensuring precise cuts and smooth operation.

Is heavy duty bed type milling machine only for large parts?

- While it excels at handling large parts, the Heavy Duty Bed Type Universal Milling Machine can also be used for smaller tasks, making it versatile enough for both large and small-scale operations.

What industries benefit from using this milling machine?

- Industries like automotive manufacturing, heavy machinery production and aerospace benefit greatly from this machine’s ability to handle large, complex parts with high precision.

Universal Knee Type Milling Machine

The Universal Knee Type Milling Machine is highly versatile, offering both horizontal and vertical milling capabilities. It’s designed for operations that require precision and flexibility.

FAQs on Universal Knee Type Milling Machine:

How is the knee-type design advantageous?

- The knee-type design allows for precise vertical adjustments, providing greater control over the workpiece. This design is ideal for operators who require flexibility and accuracy for different milling tasks.

Can this machine handle heavy-duty milling?

While the Universal Knee Type Milling Machine is versatile, it’s more suited to medium-duty tasks rather than heavy-duty milling. It’s best for applications that require precision and versatility in part sizes.

What types of jobs is this universal knee type milling machine best suited for?

- It’s perfect for operations like drilling, milling and slotting, especially for custom or small parts. It’s commonly used in tool shops, repair shops and production environments where flexibility is key.

Universal Swivel Head Milling Machine

The Universal Swivel Head Milling Machine allows the operator to adjust the milling head to various angles, providing greater versatility for complex cuts and operations.

FAQs on Universal Swivel Head Milling Machine:

How does the swivel head feature improve milling?

- The swivel head feature allows the milling head to be positioned at various angles, enabling more complex operations such as angled cuts or compound machining. This flexibility makes it perfect for producing parts with intricate geometries.

Is this universal swivel head milling machine suitable for heavy-duty applications?

- While the Universal Swivel Head Milling Machine offers excellent flexibility, it’s typically used for precision tasks. For heavier operations, other models like the Extra Heavy Duty Milling Machine might be more appropriate.

In what industries is this machine commonly used?

- The Universal Swivel Head Milling Machine is commonly used in industries that require detailed and intricate machining, such as aerospace, automotive and mold-making.

Conclusion

Milling machines are a cornerstone of modern manufacturing. Each type, from Vertical Turret Milling Machines to Universal Swivel Head Milling Machines, offers unique advantages for different applications. By understanding the features and capabilities of each type, you can select the right machine for your needs, ensuring that your milling operations are efficient, precise and cost-effective.