A Turning Machine is a machine that turns workpieces into various shapes. This process involves rotating a part while a single-point cutting tool moves parallel to the axis of rotation. The process can be performed on the external or internal surface of the workpiece. In most cases, the starting material is a workpiece generated by other processes. However, some parts may require secondary processes such as polishing or platonic solids.

Typically, turning operations are carried out by machining the workpiece. The axes of movement can be axi-symmetric or curved. The component that undergoes turning operations is termed a Turned Part or a Machined Component. This process is used for the manufacture of prototypes and limited runs. It is also a popular choice for the refinement of features on parts. A Turning Machine is known for its high tolerances and high surface finishes, making it a popular choice for precision rotational features on parts.

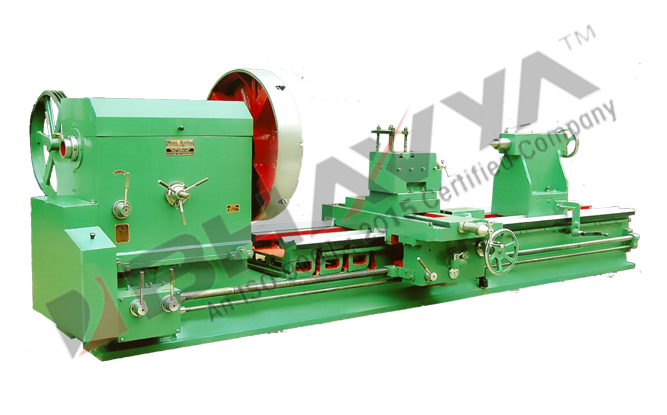

About Turning Machine

The Turning Machine is a machine for the rough and finish machining of metal workpieces. These machines can produce end surfaces and internal openings and are widely used in different industries. They can produce small and large parts, prototypes, and tools. The highest degree of accuracy and precision are possible in this type of machine, which is ideal for adding rotational features to parts. However, many of these machines are very expensive, and are therefore only suitable for small and medium-sized businesses.

The basic components of a Turning Machine are: a bed and a spindle. The bed of a machine houses all of its components, including the motor and drive system. The headstock assembly is the front section of the machine, and contains the headstock assembly and the spindle, which support the workpiece. The turning machine can perform a wide variety of operations, depending on the material it is made of.

The Turning Machine has three main components: the spindle, the bed, and the tailstock assembly. The tailstock assembly supports the workpiece when it is rotated. The spindle is driven by a motor, and it is also used to cut threads. The tailstock assembly isn’t used for all operations, so it is essential to know what to look for in the cutting tool before purchasing one. The tailstock assembly is not always necessary for every operation.

Working of Turning machine

The Turning machine is an abstract computer that displays increasing numbers of 1s separated by 0s. This type of machine can also represent a simple concept such as the print of “x” or “f” and the absence of an empty cell. The state register is where these data are stored, and it is the Turning machine’s equivalent of a human’s state of mind. Let’s look at how this machine works.

A Turning machine begins in state A, and moves to the right when it reads a number. This state changes to B whenever it reads a number. Whenever the number 0 is read, the machine moves to the right. When it reads a blank, it moves to state C. This state also halts the program when it reads the first 0 in the table. Consequently, the Turning machine is a powerful tool.

A Turning Machine is used to create rotational parts. The process is generally axi-symmetric and produces a wide range of features. In addition to generating prototypes and small-batch products, it can also be used to create and refine the features on parts. This process is also capable of offering high tolerances and surface finishes, making it a popular choice for machining rotating components. This method can be effective for a variety of applications and can produce precision parts.

A Turning Machine uses two tools: a cutter and a lathe. The cutter is a single-point cutting tool that feeds into the rotating workpiece. The lathe and cutting tools are fixed to the bed, which is large and sturdy. It will cut off the material in tiny chips. This process is also efficient for prototype production. The finished product may be much more precise than a prototype. In other words, a Turning Machine can improve precision and reduce manufacturing costs.

Types of Turning Machines

There are several different types of turning machines. Depending on their use, they can process ferrous or non-ferrous metals. Some of these types of machines are computer numerically controlled (CNC), while others are conventional lathes. Depending on their function, CNC turning machines can perform various operations, including rough and finish machining. Many of these machines are also equipped with a number of features, such as closed loop control, angle-dividing feed, and a second carriage gearbox.

The types of turning machines available vary in size and features. They can be classified by the control method they use, as well as the size of their workpieces. While both types of turning machines are capable of producing high-quality parts, CNC turning machines are more complex and expensive. In addition, these machines require a skilled CNC controller, which can increase their cost. If you’re looking for the best tool for your specific needs, a CNC lathe may be a great choice.

A Turning Machine can produce a wide range of features. It can be used for internal and end surface turning. This type of machine is popular for prototype and small batch production. Many other types of manufacturing utilize this type of machine. It is used in industries such as the textile industry, petrochemical industry, and valve and roller manufacturing. It can be used for a wide variety of applications. Its high precision makes it an efficient tool for many different processes.

Functions of a Turning Machine

The Turning Machine is an example of a simple computer program. Its head can perform one task when in state 1 and another task when in state 2. When the machine is in state 1, it can exchange the position of two strings, while when it is in the other state, it will do nothing. Similarly, when in state 2, it will do two different tasks, and vice versa. If the halt state is not defined, the machine will stop.

A Turning machine is a computer program that is capable of recognizing different kinds of problems. These programs are written in languages that describe the problem. For instance, the computer program “one” might compute the value of every string of one’s. For example, it could make the machine write a 1 whenever it moves to the right. The computer would then always move to the right. Similarly, it could make the machine write a 0 when it moves to the left.

Other Features of Turning Machine

In addition to the tailstock, a Turning Machine also features a carriage. This carriage slides along the workpiece and rests on tracks on the bed. The carriage is moved forward by a lead screw, which is usually powered by a motor. Depending on the material of the workpiece, the tailstock assembly is the most efficient option. A Turn machine can also produce the most complex precision parts. It can turn bar up to 32 mm in diameter.

The Bottom Line

When computing problems, Turning machines are often useful for solving different kinds of problems. The resulting machine can recognize a variety of languages and problems, including “1” and “111111111”. For example, a Turning machine can be instructed to compute strings consisting of 1s, such as “move to the right when I reach M.” If it moves to the left, it will write a 1.

Theoretical computer science emphasizes the resource requirements of algorithms, including computational space and time. The gold standard for calculating computational complexity, Turning machines are non-cheaters and do not allow humans to cheat.

Turning Machines can be used to manufacture parts that rotate. A turning tool will move linearly along the axis of the workpiece while the cutting tool will rotate the piece. The end result will be a cylindrical shape. A Turning machine can be used to make small, intricate parts. Unlike other types of machines, it is often cheaper to use a CNC-controlled lathe machine than to buy a traditional CNC-lathe.