There are many reasons why you would need to purchase a power press. They come in various shapes and sizes and have various benefits for different working conditions. This can be an extremely useful tool when used the right way. Some may be geared towards professional use while others may be used by amateurs. There is also a range of commercial presses including those that can be used at the workplace and those that are more suited for the home. The two most popular categories of power presses are hydraulic and mechanically driven.

Why Use Power Press??

Although these two have similar features, the hydraulic power press is still the most commonly used throughout the industry, mainly because of its long lifespan in industry. A lot of people who work in industries, especially those dealing with heavyweights and high temperatures tend to use the hydraulic variety. There are many benefits associated with both types of press but. If you have a specific application that requires a hydraulic type, then it is better to go in for a clutch fitted power press rather than a hydraulic one.

Larger hydraulic type presses usually have a much longer life span and can easily sustain a lifetime of around 200 or more uses. The main reason behind this is that they have a stronger transmission setup. The hydraulic type also has a more durable die setting, a larger die area, higher heat tolerance and can be protected from rough surfaces with the help of a guard.

Advantages of Power Press

One of the most common advantages of both types is that they require less maintenance. They are also highly reliable and you need not bother about changing a belt as often since the clutches are always engaging and disengaging.

Power Presses with two-hand controls are highly popular in various industries, particularly those dealing with plastics and rubber. They are popular with press operators of other related industries due to their easy usability, versatility, and reliability. It is important to note that when operated with less than full force, these machines can produce limited results. As a result, if you want your presses to be more productive, you need to use them when pressing heavy amounts of weight.

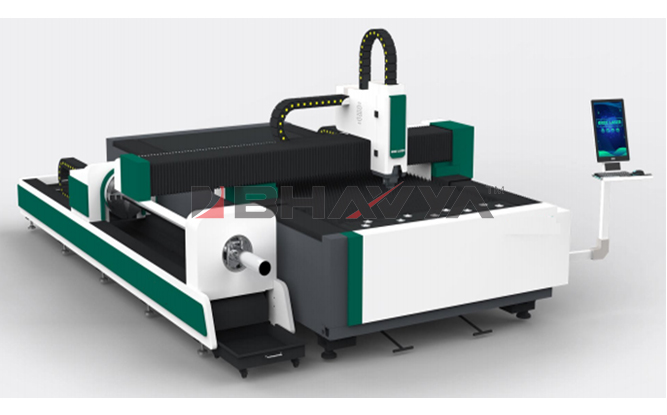

What is Fibre Laser Cutting?

What is Fibre Laser Cutting? The laser cutting process substitutes mechanical tools with invisible electrical beams. It has much higher accuracy, faster-cutting speed, reduces material from the cutting surface by using automatic typesetting, and also saves more material by utilizing a controlled cut pattern. It has a flat, smooth finish, and typically has low post-processing costs. The main product of this process is very thin layers of brass and copper. These are often used for interior design purposes. For instance, brass can be incorporated into furniture design, door handles, faucets, panel designs, etc. Copper on the other hand is used in circuit board manufacturing, air conditioning systems, and even computer chips. The combination of the two allows for greater customization in the production process and ultimately in product quality

Different Types of Lasers Used In This Process

If you are looking at stainless steel tooling, there are a few different options. The first would be carbon steel which is a more expensive option than plain stainless steel. The machines must be very precise to prevent overheating and damage to the workpiece. Carbon steel is typically used as a maintenance-free cutting surface.

With regards to using this with stainless steel, CNC plasma cutting and direct metal laser cutting are all possibilities. The most important thing to remember is to invest in high-quality equipment so you get the most out of your investment. You don’t want to end up with a product that does not work right.