Traditional Press Setup

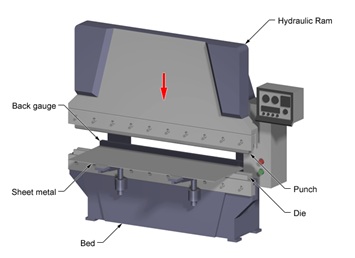

Traditional press brake setup was found to be with hydraulic principle and the usage can be traced back to ancient Mesopotamia and Egypt. Later as years went on Greeks introduced some changes into the provisions considering suitability and ease of working. However, inception of electronic or motorized tool was also introduced during traditional times in which electric servo motors were used in addition to pulleys and belts. Scott Ottens, Manager of Amada America Inc, observes about this bending tool that “In Hydraulic system there will be acceleration. It takes a little bit of time to get up to speed where in an electrical system it is almost instantaneous”

Why setup of equipment is mandatory?

Traditional press brake setup was found to be with hydraulic principle and the usage can be traced back to ancient Mesopotamia and Egypt. Later as years went on Greeks introduced some changes into the provisions considering suitability and ease of working. However, inception of electronic or motorized tool was also introduced during traditional times in which electric servo motors were used in addition to pulleys and belts. Scott Ottens, Manager of Amada America Inc, observes about this bending tool that “In Hydraulic press brake system there will be acceleration. It takes a little bit of time to get up to speed where in an electrical system it is almost instantaneous”

Why setup of equipment is mandatory?

Setup or tooling alignment is a mandatory aspect if you are looking for precise work for long term. There are certain kinds of mistakes which can be identified as general issues in metal working apparatus like press brake. However, these things depend a lot in setting up the arrangement of device parts.

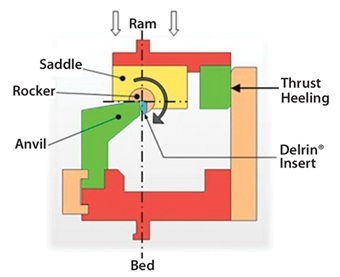

Mechanism and Machining alignment in conventional Press Devices

Revisions Required

1. Tool Selection for Process

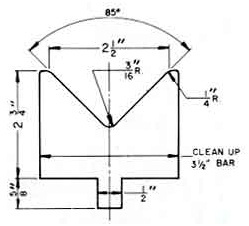

Selecting of tooling options is one of the mistakes that need to be reduced when it comes to obtaining precision in tooling work. It will also have impact on the working bed, hence the tooling components has to be consistent without bends or flanges as frequent operations may worn the components and may lead to cause bends or damages on the working beds. This could be one of the mistakes that lead to imperfect press mechanisms.

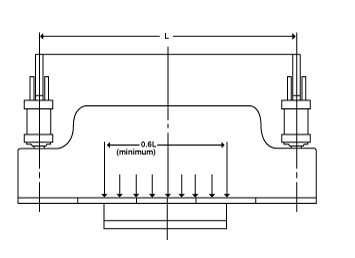

2. Creation of set up procedures

Set up procedure depends a lot on overall specifications. Every aspect of assembling has to go in tune with one another to reach maximum compatibility. For example,

- The Ram gibs should be maintained in parallel position to avoid twisting movement. This will lead to cause imperfect machining and would become tough to reach perfection.

- The return pressure should be maintained without increasing ram stroke.

- Strictly following the recommended clearance for gibs is yet another way of achieving successful set of connections.

3. Failure in Lubrication

Lubrication is one of the major issues found both in earlier times as well as today. Successful working of equipment depends on how the operator follows instruction for lubricating all the moving parts of the apparatus. The manufacturers have a big role to play in this because a good manufacturer should provide all the instructions concerning lubrication and other maintenance features.

4. Layout strategy

Layout strategy deals a lot with incorporating equipment set up, maintenance of equipments and following the recommendations in the same way as provided by the manufacturer.

5. Ram Set Up

Ram provision is one of the most commonly made mistakes when it comes to imperfections in brake technology. It has to be compatible with the work material load as overload can lead to deflection of ram. If overloading ends up in machining deflection it can be set right only through re-machining the work material placing platform or bend and the ram. However, this can become a hectic process and disturb production.

Conclusion

Press Brakes are important equipment which had been in existence since earlier times. However, successful production can be reached by avoiding the above mentioned list of common errors.