With the growing manufacturing industry, milling machines have replaced the role of other types of equipment. It is one of the most important machine tools in the manufacturing industry. Initially, milling machines were been experienced for a simple processing equipment, but today it performs multi-functional high- intelligent processing. The development of the milling machine shows high performance, intelligence, environmental protection integrated machines. Not only simple processing but has also shown a tremendous change in electrical appliances, transmission structure etc.

Milling Machines in different industries are designed for machine shops and different industries to manufacture high precision products and parts of different size and shape. Apart from this milling machine can also perform tasks such as drilling, cutting gears, producing slots and many more.

There are different types of milling machines been used that is described as follows –

All Geared Universal Milling Machine

All Geared Universal Milling Machine is been designed to shape metal and other solid materials. It can be operated manually, automated and digitally automated CNC milling tools. This machine is highly efficient due to its high cutting capacity that is generally been used in large-scale industry. Depending on the type of industry as small scale or large scale, the machine is available in different specifications. Different models are been available for all geared universal milling machine considering the working surface, the range of spindle speeds and many more factors

All Geared Vertical Milling Machine

All Geared Vertical Milling Machine is been specifically designed to meet the requirements of engineering, process and construction industries. There are various features of this type of machines that includes low maintenance, safety, high productivity & quality. This machine is known for its high efficiency and cost-effective performance. Its properties like high tensile strength, perfect milling offers flawless shaping for solid materials.

Universal Milling Machine

Universal Milling Machine is used for processing of different surfaces that includes parts for serial production. With the help of this machine milling of helical, horizontal, grooves, fissures, angles can be performed. It can also be split as a vertical & horizontal milling machine.

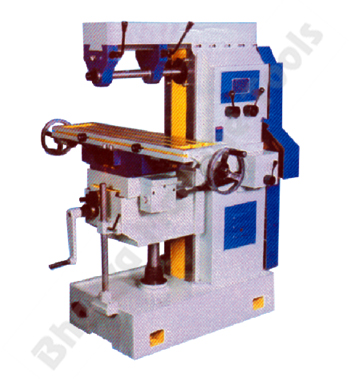

Vertical Turret Milling Machine

Vertical Turret Milling Machine is assorted for milling jobs for shaping metal and many solid materials. This machine is economical and stable due to its various features that include durability, reliability, efficiency and higher productivity. It can perform multi-axis machining with different operational modes that includes manually operated, mechanically operated and digitally operated automated CNC mills. It provides high stability with rectangular table guideway, automatic motorized lifting and lowering of the product.

Considering the demand of the milling machines in different industries Bhavya Machine offers different types of a milling machine. The above-mentioned milling machine has a different application in industries. With the milling machine, we also offer different types of machines used in industries that include welding machine, different types of lathe machine, shaping machine, CNC machines and many more. We are also dealers in specialized machines that include welding machine, food processing machine, sheet metal machine, and other special purpose machines.