When selecting an NC bending machine, you will want to consider the price, specifications, features and functionality of each one. In this article, we’ll look at what to look for, as well as the pros and cons of each machine. Once you know what to look for, you can narrow down the choices to the best one for your needs. Read on to learn about some of the benefits of NC bending machines. And don’t forget to read our buying guide for more information.

Features of NC Bending Machines

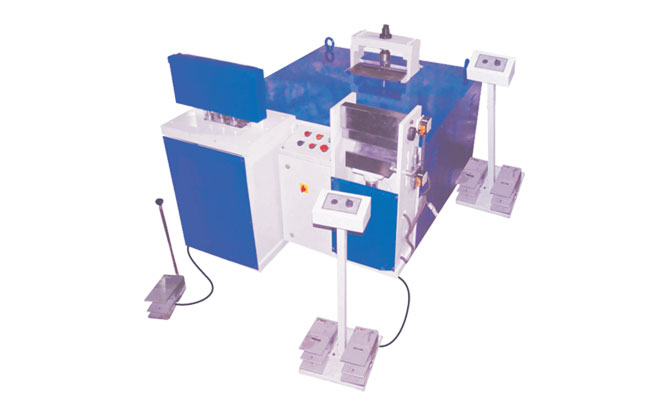

An NC bending machine combines multiple functions, energy-saving features, and advanced design features. Depending on the model, it can be used for bending pipe sizes. Its easy operation and movement make it ideal for quick installation and efficient processing. A CNC bending machine can be programmable and can produce complex shapes without the use of a reference part. It also features a safe control system that ensures consistent bending quality even when the machine is unused.

During the operation, all personnel should be commanded by a person who knows the basic functions of a CNC bending machine. The main operator must be able to control the foot switch to control the operation. The pressure should not be too high when bending a large part. The bending pressure should not exceed half of its maximum value during an eccentric load. It should also be equipped with an emergency stop button. These are only some of the advantages of an NC bending machine.

How to Choose the Right NC Bending Machine for Your Business

When selecting an NC bending machine, there are several factors that should be considered to ensure it fits the specific needs of your operation:

- Material Compatibility: Make sure the machine can handle the types of materials you work with, whether it’s aluminum, stainless steel, or copper. Each material has different bending requirements, so it’s important to choose a machine that offers versatility in handling these materials.

- Pipe and Sheet Size: Consider the maximum size of pipes or sheets the machine can accommodate. If you work with large pipes or sheets, you’ll need a machine that can handle heavy-duty bending without compromising on precision.

- Bending Radius and Angle Control: If your work requires intricate bends, choose a machine that offers precise control over the bending radius and angles. Some machines provide customizable settings to meet specific project requirements.

- Automation Features: For high-volume production, it is beneficial to choose an automated NC bending machine that allows for multi-step bends and integrated punching capabilities. This automation will speed up production and reduce manual labor.

By considering these factors, you can ensure that the machine you purchase is the best fit for your business needs, providing maximum efficiency and cost-effectiveness.

NC Bending Machines Functions

An NC bending machine is a type of CNC bending machine. These machines can perform various bending operations on metal sheets, including forming rounded corners and bending sheet metal at varying angles. These machines are widely used in the automotive, aircraft, light industry, and container manufacturing industries. They are equipped with high-definition LCD screens and user-friendly interfaces.

CNC bending machines are controlled by a specialized computer. Its software can automatically calculate the pressure required for the cylinder, which is a vital part of the bending process. It is also possible to connect this type of machine to an external workstation. Many CNC bending machines also have a punching machine that produces holes in the bending parts before they are shaped.

As the technology advanced, NC bending machines could control and automate more functions. Users could develop the system software for CNC bending machines, and the machine’s scope of applications was no longer limited to the manufacturers’ standards. The latest generation of CNC bending machines also adopted a modular design to meet the needs of various users. These machines could be programmed to change the bending time of individual parts.

Technological Advancements in NC Bending Machines

Over the years, NC bending machines have evolved significantly with the integration of advanced technologies. Some of the most important advancements include:

- Smart Software Integration: Modern NC bending machines are now equipped with smart software that optimizes the bending process by calculating the precise bending parameters, ensuring accurate and consistent results. These machines also provide data analytics, allowing for performance monitoring and maintenance tracking.

- Hybrid Machines: The latest trend in NC bending machines is the development of hybrid machines that combine the best features of both hydraulic and electric bending machines. These hybrid machines provide higher energy efficiency and more precise control over the bending process.

- Laser and Sensor Technology: Advanced laser sensors are now used in NC bending machines to ensure exact positioning and alignment of materials during the bending process. Laser-guided machines also help in ensuring that bends are within tight tolerances, improving the overall quality of the output.

- Increased Automation: New models of NC bending machines include automated loading and unloading systems, which enhance productivity by reducing manual labor and ensuring a seamless transition between bending operations.

These technological advancements make NC bending machines more efficient, precise, and easier to operate, helping businesses to meet the growing demand for high-quality and complex bent products.

Specifications of NC Bending Machines

When considering the NC bending machine, you should be aware of its specifications. Its basic features include micro-adjustment for pressure die, ball mandrel protection, and programmable time for bending movement. This bending machine is an excellent semi-automatic solution for various types of bending applications. Its programmability is another plus point.

Features of the machine: It can be operated with an integrated circuit and solenoid valve. Its software can automatically detect malfunctioning points and correct them. It is also equipped with a three-step hydraulic oil flow to prevent the deterioration of the oil. It also has a manual hydraulic adjusting valve for large tube bending. It can be programmed to work multiple bending sequences. Its automation makes it a highly versatile machine that is capable of bending different materials, such as heat exchangers.

Safety Features and Considerations

Safety is a critical factor when working with NC bending machines, as the machinery involves high pressure and precise movements. Some important safety features include:

- Emergency Stop Mechanism: Every NC bending machine should be equipped with an emergency stop button that immediately halts the operation in case of an emergency. This feature ensures the safety of the operator and prevents accidents.

- Guarding and Shields: Machines should be equipped with safety guarding around moving parts to prevent accidental contact. Additionally, protective shields help to prevent debris and sparks from flying towards the operator.

- Operator Training: Given the complexity of NC bending machines, it’s essential that operators are properly trained. They should be familiar with the machine’s functions, safety features, and troubleshooting procedures to avoid errors and accidents.

- Automated Safety Checks: Modern machines can perform automated safety checks, ensuring that all parts are functioning correctly and that there are no malfunctions before the machine starts operating. This minimizes downtime and potential safety hazards.

By prioritizing safety in the setup and operation of your NC bending machine, you ensure a safer work environment and protect your investment in machinery.

NC Bending Machine Price

The tube bender offers maximum flexibility and can produce large outside diameter and heavy-wall bends. It is a high-end machine used in industries such as turbines, bellows, and turbo pipes. Its flexibility and quality large-bending capabilities reduce the need to rely on outside suppliers and boost profit margins. These machines are also popular in the mining and agricultural industries. However, there are a few important factors to consider before purchasing an NC bending machine.

First, the computer numerical control system is much easier to use. The operating system is user-friendly, and the user can quickly learn how to use it. Operators must be knowledgeable about every function of the machine and operate it precisely. NC bending machines come with advanced storage features that allow users to store multiple programs. The larger the system’s storage capacity, the better.

Installation of NC Bending Machines

The main functions of an NC bending machine are pipe bending, slitting, forming, and repairing. Moreover, these machines are widely used in many industries, such as electric power, highway and railway construction, boilers, ships, and other pipe-related projects. The advantages of CNC pipe bending machines are, multiple functions, reasonable structures, easy operation, and smooth movement. Moreover, these machines can be easily and quickly installed.

A CNC bending machine has numerous advantages, such as the ability to make adjustments automatically, easy program modification, and high efficiency. Its hydraulic system consists of a ram, an oil cylinder, and a mechanical stop fine-tuning structure. It is equipped with a numerical control system that figures out the required crowning force during the bending process. The CNC system enables the machine to process parts according to drawings and specifications.

Cost Considerations and ROI of NC Bending Machines

When purchasing an NC bending machine, it’s important to consider the overall cost and return on investment (ROI). While these machines can be a significant upfront investment, they offer long-term benefits, such as:

- Increased Productivity: By automating the bending process, NC bending machines help reduce manual labor and speed up production, ultimately increasing throughput.

- Reduced Material Waste: The precision of these machines ensures that material wastage is minimized. Accurate bends reduce the need for rework and scrap material, leading to cost savings.

- Lower Labor Costs: Since NC bending machines are often automated, fewer operators are required, reducing labor costs over time. The reduced reliance on manual labor can significantly impact profitability, especially in large-scale operations.

- Enhanced Quality Control: The ability to program and automate the bending process leads to consistent and high-quality results. This is essential in industries where product quality and precision are critical, such as aerospace, automotive, and electronics.

Evaluating the long-term ROI of an NC bending machine is crucial to understanding the value it brings to your business. Although the initial purchase price might be higher, the efficiency gains, cost savings, and increased production capabilities can lead to a strong return on investment over time.

The Bottom Line

Bhavya Machine Tools offers CNC bending machines that are known throughout the world. The most important feature of an NC bending machine is its ability to automatically measure the unfolded size of the workpiece. This allows it to meet the design requirements for accuracy. A CNC bending machine can also be equipped with a punching machine, which can be used to cut holes before bending. This helps improve the bending process and overall production efficiency. Further, an NC bending machine can be connected to an external workstation for processing.

Future Trends in NC Bending Machines

As the manufacturing industry continues to innovate, NC bending machines will continue to evolve to meet new challenges. Some emerging trends include:

- Sustainability and Energy Efficiency: With a growing focus on sustainability, manufacturers are increasingly designing NC bending machines that consume less energy and reduce environmental impact. This trend is in response to global demands for greener manufacturing processes.

- Integration with Industry 4.0: The advent of smart manufacturing means that future NC bending machines will be connected to broader production systems via IoT (Internet of Things). This will allow real-time data collection, performance monitoring, and even predictive maintenance, enabling businesses to run more efficiently and reduce unplanned downtime.

- Enhanced Automation: The future of NC bending machines lies in greater automation. With the integration of robotics, automated material handling systems, and real-time machine learning capabilities, these machines will become even more efficient, further reducing the need for human intervention.

- Customizable and Modular Designs: As demand grows for more specialized parts, manufacturers will increasingly turn to customizable and modular NC bending machines that can be easily adapted for different tasks and materials. This flexibility will help businesses address a wide variety of bending requirements.

These trends indicate that NC bending machines will continue to play a crucial role in shaping the future of manufacturing, offering businesses more precise, efficient, and sustainable options for their production lines.