Multiple Machining Facets of Workshop Tools

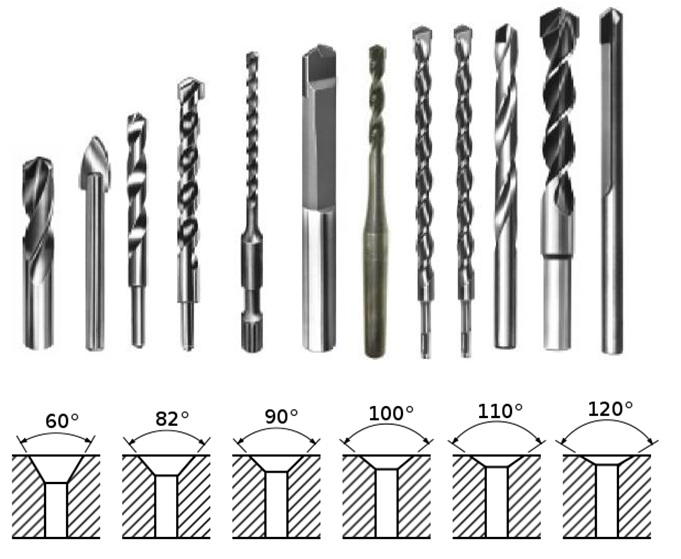

Most of the workshop tools are featured with multifaceted operational aspects. Single equipment may be defined for specific operation like cutting, drilling or surfacing, yet, as far as flexibility is concerned, the same device is eligible for varieties of machining works. Machines like drill, press, mill, lathes machine, etc come under this category as they are meant for more than the specific form of working. Creation of cone shaped hole is one among the most required works, this is called countersinking. A drill is the prime apparatus that stands suitable the above work, however, lathe, mill; drill press can also be applied to same purpose.

Countersinking Complications

Creating holes on work materials ranges may not be questionable unless the kind of material or position in which hole is required may remain complicated. Countersinking is a right method to manage tricky forms of drilling. Yet this process should be managed in a strategic method to avoid the possibilities of complications which vary in accordance with material.

Material Issues and Recommended Strategies

Titanium– Metals like Titanium remains a challenging raw ingredient during the process of backing off the cutting edge. This can be solved through the selection of spring in drilling equipment. The harder the work piece is, the stiffer and special the spring should be selected.

Wood

Application of sharp tools suits best to attain smooth dimension in wood. Apart from that, ensuring screw head and high rake angles works better to obtain better cut angles.

Plastic

Drill is best equipment suitable for cone type drilling in plastics such as acrylic, Teflon, fiber, etc. It is found to bring our better results by using a drill than other eligible equipments for the above kind of operation

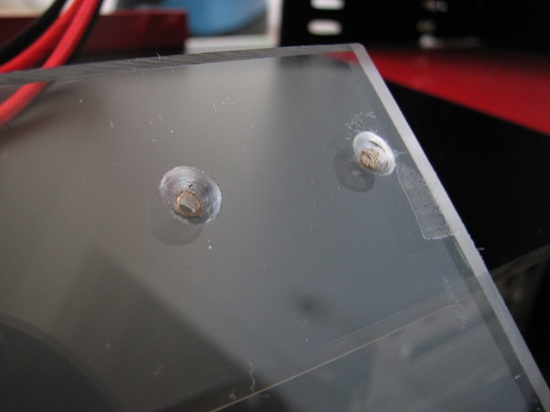

Acrylic

Acrylic is also a challenging material in forming conical holes is concerned. Simultaneous contraction of opposite sides of the hole had been the trouble during the application and the strategy remained in pressing the hole contour and apply lighter cut. Next, the numbers of RPMs were also determined in accordance with removal of residues to reach precision.

Important Rules Which May Help to Restrict Issues

- In order to prevent disturbances, apart from countersinking, even chamfering also required special considerations. This will help in preventing burrs forming in between layers and from forming fuzzy edges and achieve good joints.

- The application is done without leaving any obvious burr, tearing out, etc

- While handling with plastics, the temperature may be noted for compatibility to stop melting

- Slow feed rate is recommended for fragile range of components

- Removing chips is a favorable condition for precise tooling.

Conclusion

Strategic way of handling complicated hole making operations helps to obtain precise performance. In addition, the ideas differ in tune with the type of work material because tool selection must be compatible with the ingredient chosen. In the same way, there are many devices which can be used for performing similar range of actions and they need to be selected based on how they go matching with work component.