Common Forms of Piercing

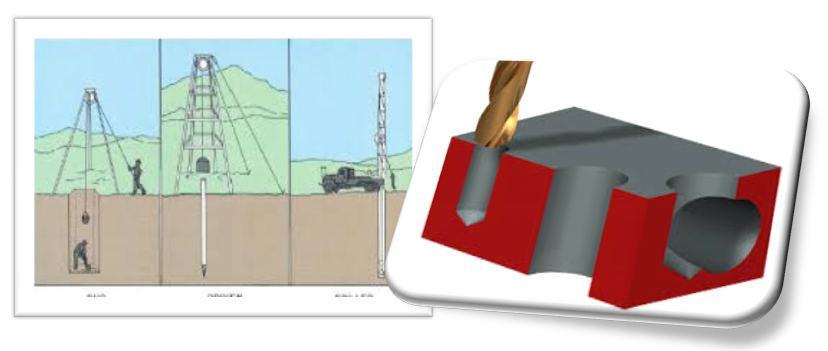

Piercing has different connotations when it comes to industrial process. It is applied in various ranges depending on the intensity required. In addition, this application is implemented over different materials and surfaces in accordance with the industry. Some of them are oil well drilling, piecing on work materials, creating holes on metal surfaces, grinding smaller to larger sized components, etc.

Metal Industries and Piercing Requisites

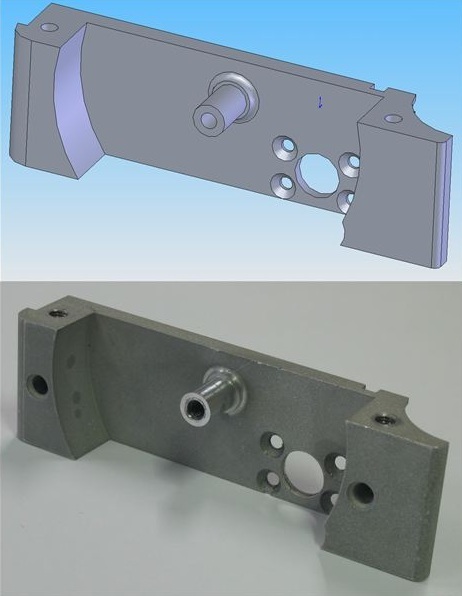

The toughest and most challenging part of piercing is the one that is done on metal surface. If the work material is heavier, it would be more challenging without the help of equipments. Metal industries require this operation for making holes, for combining two or more components at a single point, shaping tools to its precise from, sharpening materials by deforming surfaces, etc.

Industries which prefer Tooling Operation

This application can be seen in automobile, machine manufacturing and many industries which make use of different types of metals, wood and plastic as raw material.

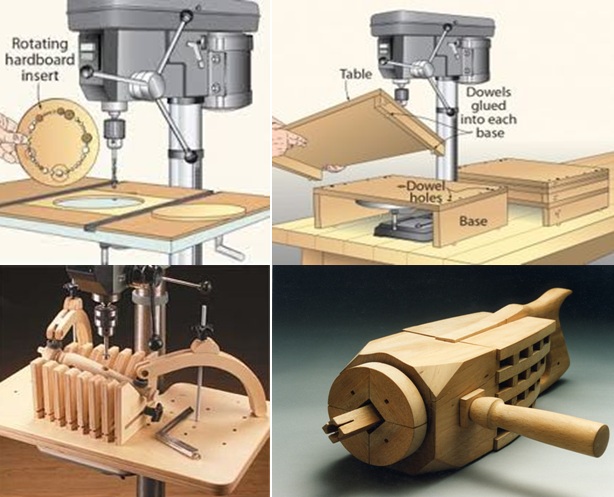

How wood works are intensified with Drill?

Boring equipment is featured with a tool bit or sharpening provision, that sharpens the specific area in terms of creating dimensional holes or cavity. The cavities have to be created based on the matching dimension to be combined with other parts to form a final product like in making of furnitures. In the same way, when it comes to wood work, boring means a lot, it remains the connective point for creating the preferred object.

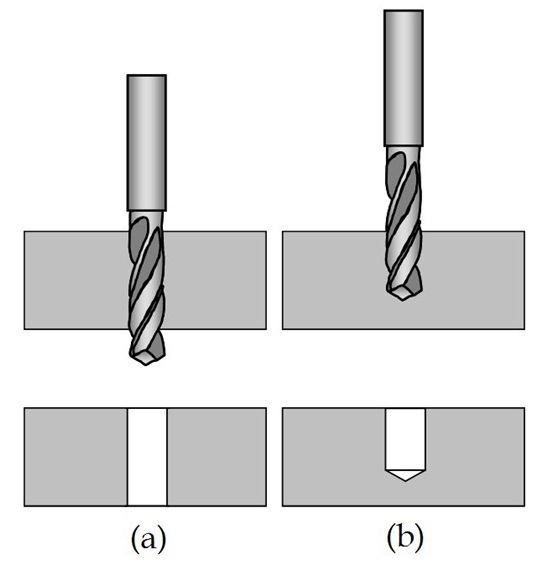

Countersinking

Countersinking is a kind of operation that helps to make cone shaped surface on the mouth of an already existing hole. It is done to link the material with flat head screw or rivet. It is applied with the help of tool bit that can be attached to the equipment. Moreover, this kind of piercing is also preferred for eliminating inflections or sharp edges present in the hole and radial drilling machine can be applied to obtain these conditions.

Creation of Holes

Holes are created for fixing requisites and for inserting more components that stay in matching dimension with that of hole. Precise of dimension is more important and this can be obtained only with the help of special equipment like pierce machine. For creating precise holes on heavy duty work materials v-belt driven radial drill will stay the ideal choice.

Grinding –Masonry Works

Grinding is yet another form of mandatory requirement in masonry wood works. It helps in removing the burrs and keeps the surface smooth. Radial device with v-belt drive works efficient for this function also.

Drilling Large Work Pieces

Radial drilling equipment is one of the top choices of machines that can be used for piercing large or heavy load work materials. This machine is available in new features such as the v-belt drive is yet another advantageous feature that helps in this regard.

Conclusion

Drilling is preferred in different industries as it is found to be mandatory to combine work materials. There are special forms of equipments that can be applied to reach precise tooling at reduced wastage.