Capitalize on your return and enhances production efficiency using sheet metal forming tools. These are well designed in ensuring efficiency accuracy and increases the mechanical performance in the metal forming industries. It is constructed with high quality materials enabling it to consistently operate throughout the life cycle.

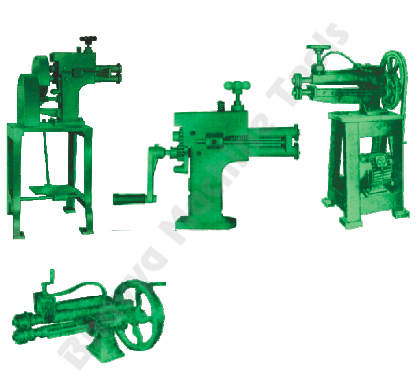

Different types of metal forming machines.

There are various devices available in the market at affordable price which include: swaging, roll type edge folding, and burrying machine among many others. They have a unique feature that enables them to cut, bend, press and forms the sheet metals into different sizes and shapes in meeting the customer current demand in the industries. It operates at high speed hence increasing the production output.

Unique features of Sheet Metal Machines.

They are manufactured from high quality standards raw materials that are internationally certified for use globally. The latest technology is incorporate in ensuring hassle free product range. The equipments are available in different standards such as 4 feet, 6.5 feet and 8 feet depending on the client needs. They have high efficiency levels and give a long life service. The control boards are accessible and easy to operate as it comprises main switch with a signal that show whether the current is flowing or not.

Application of Universal & Deep Throat Swaging Machines in Sheet Metal Forming.

Universal and deep throat swaging machines are highly used in the heavy metals industries in altering the metal sheet into different shapes and sizes as per required form. It is also used in making medium sizes drums and households containers such as water buckets.

Special Features of Universal & Deep Throat Swaging Machines.

It is technically advanced in the metal sheet forming industries that support a large thickness and length. It is quite efficient to both metallic and non metallic materials. They are complete with six roll set roll such as curling rolls, flanging roll, adjustable depth gauge, handle, motor mount and motor pulley. These are very useful in swaging drum and containers.

Applications of Jenny /Burrying Machine in Sheet Metal Forming.

It is available in the market in two forms that is hand operated and motorized jenny or burrying tools. They are used in tin plating edge and flange or hurrying the edge. The forms tins and containers into different sizes and shapes depending on the current demand in the market.

Machines Used for Edge Rolling and Forming Processes.

Roll type edge folding swaging is used in tin edging and forms hooks on the seams and tin flanging. It uses a variety swaging and creates containers into different attractive sizes and unique shapes. It is highly distinguished in the market offers a wide range of folding and bending forming process.

Conclusion.

They are several metal sheet equipments available in the market with the highest quality range as are suitable in different metal work sizes such as forming, cutting, bending and folding. The metal sheets includes: jenny or burrying, sheet metal swaging, universal and Deep Throat Swaging, and roll type edge folding. These are cost effective, easy to maintain, cost effective, durable, and affordable and makes the work easier in industries. All these special features have increased production and maximizes on the returns.