If you’ve been considering an NC Bending Machine for your business, you’ve probably wondered about the benefits and limitations of these machines. In this article, we’ll look at the cost, flexibility, and variable nature of NC bending machines. You’ll also discover what makes them unique and effective for your needs. Ultimately, an NC Bending Machine will be the best choice for your business. Read on to discover the benefits of NC bending machines.

Benefits of NC Bending Machine

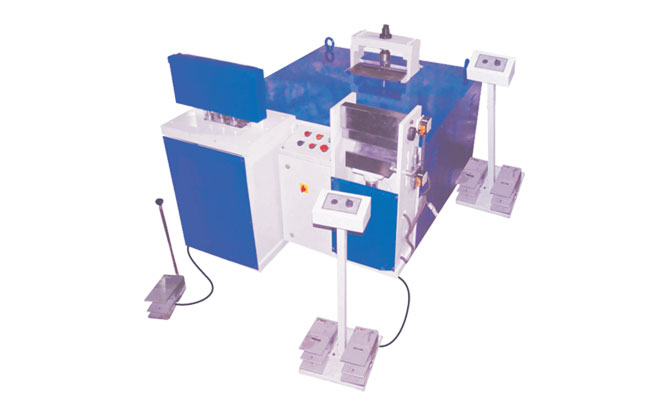

In terms of speed and quality, an NC bending machine is more efficient than a standard forming machine. It can produce bends with greater outer diameters. However, its price is comparatively high compared to other forming machines. Its bending outer diameter is greater than the processing radius of conventional equipment. Furthermore, the machine’s control system includes data and graphics programming functions. These features make it a good choice for small and medium-sized companies, who want to cut and shape small tubes, plates, and profiles.

With the assistance of the computer, operators can adjust the sequence of bends to produce the best possible result. The operator does not need to guess the pressure needed to bend a part; he can simply input the sizes and steps into the NC control system. Another advantage of NC bending machines is that they can be programmed offline, which makes it easier to meet high requirements.

Variability of NC Bending Machine

A NC bending machine can be programmed on a PC with specialized software. The NC bending machine can be configured for multiple parts and can be connected to an external workstation for a variety of other purposes. Part programs are stored in a database for easy retrieval. The software asks for all necessary input values and checks all figures. It can be programmed to calculate the flat length of the part for each different process, and it can determine the exact position of a side stop.

NC bending machine have a high level of synchronization performance and can work at high efficiency. In addition to this, NC press brakes are equipped with a computerized control system. They are highly accurate and have a flexible range of bending. The operation is simple and requires minimal experience for operators. It can also simulate bending without trial bending. These NC bending machines have many other advantages that make them more suitable for production operations.

Flexibility of NC Bending Machine

An innovative NC bending machine offers no limits to bending. Its compact and leading-edge design enables it to process more materials with less effort. Moreover, the NC system can store processing data and transfer it to similar machine tools. It can store bending processing experience information such as bending order, mold type, setting position, and matters to be attended to. Then, the bending machine can be programmed to carry out multiple bending sequences with a single operation. In addition, it can also handle a variety of bending materials, including steel, aluminium, and stainless steel.

The NC bending machine offers multiple functions and is highly flexible, allowing it to perform different types of bending operations on metal sheets. They also feature rounded corners and the ability to bend at different angles. It is used in the automotive, aircraft, and light industries, and can produce intricate shapes without reference parts or specialized tools. The NC bending machine has advanced storage capabilities and is often connected to an external workstation for more customization.

Final Thoughts

The cost of NC bending machines depends on their size and processing capacity. A small model can be used for one-dimensional bending. Larger machines are suitable for multi-axis bending. They can also be used for three-dimensional bending. The price of a NC bending machine is relatively high, but its benefits make it worth the investment.