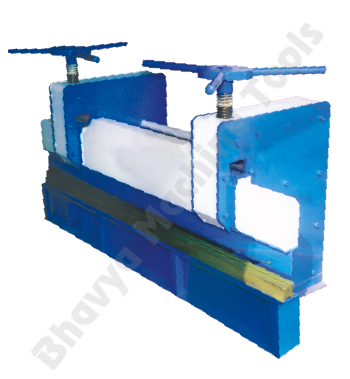

One Machine to Handle Variety of Metals

Steel, brass, aluminum, copper, etc. these metals can be converted to variety of shapes even when they are existing in varying thicknesses.

Important Aspects to be looked for in Sheet Bending Equipment

Starting with tooling, to width of bend, bend angle, unique bending possibilities, are some of the important aspects to be considered while investing in sheet bending equipment. Metal sheets are difficult to bend as per the expectation or decided measurement, however metal bending equipment is the right choice to perform shaping operations for variety of materials.

What is Bend Angle and how it is decided in Metal Bending Machine Mechanism?

Bend angle is the desired angle of bend expected in metal work piece which is calculated considering 180* as the starting angle. Every meandering operation is decided starting with 180* angle to make the machining easier and precise.

Bend Angle Requirements in Industries

It is the process of applying force through machines beyond the work piece materials yield point and not above its exact tensile capacity. The metal work piece is stretched by the force and compressed as per the required radius. The mid-point of the bend is considered to calculate the bend angle

Bend Allowance –An Important Operational Aspect to be followed in Metal Bending Equipment

Bend allowance is the final decision made on shape transformation in work metals. It requires good experience to calculate the bend angle with respect to the type of work piece provided. Since, not work materials vary in thickness bend allowance also has to be calculated based on the thickness and the time required to shape the metal.

What does Bend Size Signifies in Bending Operation?

Curving size is a synonymous term referred to bend angle. It is the shaping requirement expected in various industries. The bend size will not be the same always as it is pre-determined with respect to industrial application and compatibility of the work material.

Possibilities of Spring back analyzed in Industries

Spring back describes the elastic property of certain work metals which gets deviated a little after bending. It becomes quite difficult to manage such materials to achieve perfect bending.

Innovative Methods to Avoid Spring back

Only experienced operators can perform this operation to avoid spring back. They try to do little more circuitous than the predetermined angle to match the variation in curve caused by spring back action.

Measures Taken by Top Industries to Obtain Precision in Bend Angle

Many leading industries check for the compatibility of work metal with the curving operation. For example, aliminium is relatively lighter than iron and copper has different tensile strength, iron is considered to be the strongest. Hence, industries prefer to choose customized bending tools to match the material compatibility with machining. Get more information about customized bending tools, visit at http://www.bhavyamachinetools.com/sheet-metal-machine.html.

Conclusion

We supplying variety of workshop devices suitable for different industries. We offer metal sheet bending equipment considering customization requests from industries. Consumers can easily obtain precise bending in angle by investing in metal shaping machine we supply.