What are combination tools?

Selection of specific apparatus stays the key point of achieving unusual kinds of shaping. Apart from implementing dies, addition of utensils can help in enhancing machining operation. This methodology also provides good results in terms of productivity. Combination of more than one device is required in certain industries during times of profile making is required.

Considerable Types of Standard Instruments

Pre-formed tool design is the foremost feature that has to be checked for before buying equipment. Each machine supplied by a manufacturer will have standard range of contrivances. Exception demand of determining like forming channel legs using metal components may require the assistance of additional instrument apart from average options.

How Grouping of Machining Gadgets done?

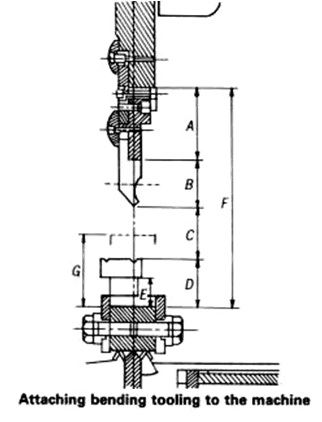

Grouping or combining normal accessories with specific accessory is the proper selection of punch and die. This method is further fortified depending on the work material thickness along with varieties of deforming basics. Optimum blending decided upon the above criteria will help to reach the necessary set up as well as precision in distorting.

Follow Stages in Shaping

As far as application of multiple gadgets for deforming is concerned, it is done through different stages. The effectiveness of blending more than the standard choice of instruments works worthwhile when done through stages. For example, the first stage the die is focused and punch action is focused during the second stage

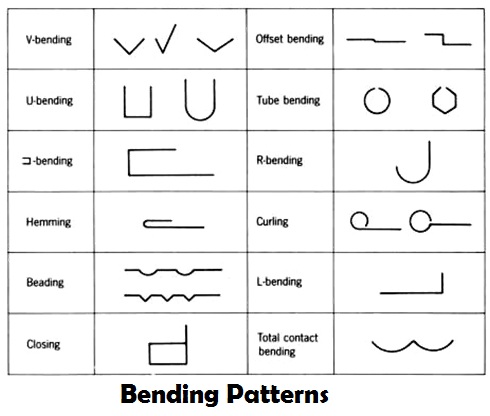

Different Shapes Formed through Combination Tooling

- Creation of Channel Legs

- Hemming

- Curling

- Acute angled winding

- 90⁰ twisting

- R, Offset, tube, U, V, Closing and beading types of bending

- Total contact form, etc

Changes Affecting Performance of Machining

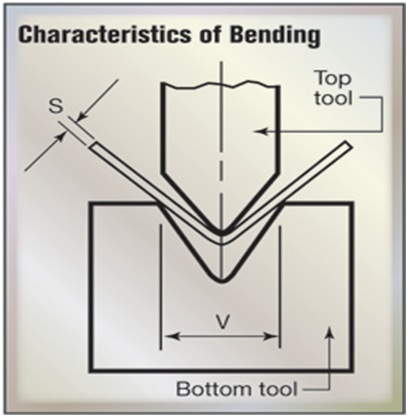

A press brake is a versatile apparatus which works over the geometrical principle of punch angle and radius also called as top and bottom tool. Successful and precise results are possible only if the mixture of both remain compatible for work piece. Strategic assortment of gadgets considering supporting factors like material strength, width, thickness, die shape, etc offers the following advantages.

- Increases capacity of device, like press brake

- Manufacturers can manage higher productivity at balanced investment

- Quick and accurate results obtained

- Eliminates high cost and repetitions

- Reduces possibilities of changes

- Create products without any instrument impressions

- Choosing a flexible die can help for better performance through replacing damaged ones without causing any changes in the already completed deformation.

Rare Happenings of Multi-breakage

Multi-breakage is a condition that occurs in R-bending. It results in prior winding before the actual machine starts its motion due to the pressure spreading in both directions. However, in heavy duty and high tensile strength materials this kind of actions occurs rarely. It should be tactically avoided by managing proportionate ration of sheet thickness and inside radius.

Conclusion

Extraordinary shaping needs are not possible with standard forms of devices. It can be done only with the support of additional components. An apparatus like press is one that can be accommodated with multiple gadgets to create unique shapes.