A lathe is a machine which is used to execute different operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with the certain tools applied to the lathe to create an object with the suitable symmetry and measurable axis of the object. Down mentioned is the detailed information of lathe machine from its history to its features and benefits.

History of Lathe Machine Invention

The origin of lathe machine invention started in the 13th century when the Egyptians first designed a two-person lathe. Later after some years, the Romansimproved the Egyptians lathe machine by adding a turning bow. Now it is a famous saying that”improvement in technology with time is sustainability”. Hence, the precision metal lathe machine is developing since the 13th century. But, during the medieval period, when the industrial revolution had taken place, the European lathe machine was on a hike, and it was also considered as the mother of all machines.

Ancient Origins of Lathe Machines

The history of lathe machines dates back to ancient civilizations. In 1300 BCE, the Egyptians developed the earliest form of the lathe-a simple two-person device. One person would rotate a wooden workpiece using a rope, while the other would shape it with a tool. This early form of lathe, while primitive, laid the foundation for the future evolution of lathes.

- Ancient Greece & Rome: The concept of the lathe spread from Egypt to Greece and Rome. The Romans added a bow to the mechanism, enabling more stability and precision in rotating the workpiece. This design improvement allowed for greater versatility and efficiency in shaping materials.

- China: Rotary lathes also emerged in China around 400 BCE, where they were used primarily for sharpening tools and weapons. These developments contributed to the spread and refinement of lathe technology in different cultures.

Medieval Developments

- Pedal-Powered Lathes: The Middle Ages saw the emergence of pedal-powered pole lathes, a significant innovation that allowed a single craftsman to operate the machine with both hands while using their feet to power the rotation. This innovation revolutionized manual machining by increasing the precision of shaping tools and enabling greater autonomy for the operator.

Revolution In Machine Tools

The Revolution in the heavy-duty lathe machine is progressive, for example, the turning tool which once used to cut few metals sheets can now cut down the maximum amount of metal sheets. The chamfering tool can more properly angle the cutting edges of materials, and the machine’s tool has fully revolutionized as the thread cutting tool, and internal thread cutting tool has also improved since the industrial revolution.

Key Technological Innovations and Advancements in Lathe Machines

Lathe machines have undergone a multitude of innovations over the centuries. Some of the most critical advancements include:

- Hydraulic and Electric Lathe Machines: During the late 19th and early 20th centuries, hydraulic power and electric motors were introduced to lathe machines. These advancements made lathes more powerful, precise, and efficient, reducing manual effort and increasing throughput.

- Introduction of CNC (Computer Numerical Control): The late 20th century marked the dawn of CNC technology, allowing machines to operate automatically by reading and executing pre-programmed instructions. This greatly enhanced the precision of lathes and reduced the need for skilled operators.

- Automation and Smart Lathes: Today, lathe machines are increasingly being integrated with automation technologies, including robotic arms and AI-driven systems. These innovations allow for autonomous operations, real-time monitoring, and continuous improvements in machining processes.

Industrial Revolution and Mechanization

The Industrial Revolution in the 18th and 19th centuries saw a significant leap in the evolution of lathe machines. Key developments during this time include:

- Power Sources: The lathe machine transitioned from manual labor to mechanized power sources, such as water wheels and steam engines. These power sources significantly enhanced the efficiency of turning workpieces.

- Precision and Metalworking: The Industrial Revolution also brought advancements in metalworking, particularly with the development of more robust all-metal lathes, which were crucial in the production of parts for other machines, including the burgeoning steam engines.

- Slide Rest: The invention of the slide rest, a mechanism that allows for consistent tool guidance, was a major leap forward. This improvement allowed lathe machines to operate with higher precision and consistency, which became essential for modern manufacturing.

Who Invented The Lathe Machine And How?

In the year 1718, a Russian engineer Andrey Nartov was the first lathe machine manufacturer, who developed one of the first lathes, which was a cutting tool with carriage support and a set of gears. The lathe machine was the first-ever machine tool, which started the utilization of equipment in industries. As the supply of different metals were high in the European countries during the time of the industrial revolution, a machine was required for the workers, which can decrease the workload and increase the speed of metal cutting and processing. Therefore the high-speed lathe machine was invented. The engine lathe machine not only helped in the fast production but was also beneficial for the accurate shaping of the metals for steam engines and other inventions during the industrial revolution.

Lathe Machine – A Mother Of All Machine Tools

Lathe machines are known as the mother of all machine tools for a specific reason, which was that the heavy-duty lathe was the first machine tool which led to the invention of other machine-based tools. During the industrial revolution, lathes evolved into hydraulic lathe machines which had thicker, more rigid parts. At the time of late 19th and mid-20th centuries, individual electric motors were introduced to the lathe which was also called as American lathe which replaced line shafting with the power source. When the mid 20th century started slowly the era of CNC lathe machine started, in which the control of lathes and other machine tools were operated via numerical control, this numeric control of machine was computerized, and the machine tool was also called computerized numerical control (CNC) lathe. And from then manual and CNC lathes both exist in the manufacturing industries.

Why Lathe Machines are Called “The Mother of All Machine Tools”

Lathe machines are often referred to as the “mother of all machine tools” because their foundational principles gave rise to many other types of machine tools. As the first-ever machine tool used for precision cutting and shaping, the lathe laid the groundwork for the development of tools such as milling machines, drilling machines, and grinders. In essence, the lathe was the blueprint for the evolution of modern manufacturing processes and continues to play an indispensable role in various industries.

Modern Era and CNC Lathes

The late 20th century marked a pivotal shift in lathe technology with the introduction of Computer Numerical Control (CNC) lathes, which brought automation to the forefront.

- Electric Motors: The transition from manual power sources to electric motors increased machine performance and reduced labor dependency.

- CNC Lathes: The most transformative innovation in the modern era was the advent of CNC technology, which allowed for automated, pre-programmed machine operations. CNC lathes could now perform precise cutting and shaping operations without human intervention, opening up vast possibilities for mass production and precision manufacturing. This evolution in lathe technology represents the culmination of centuries of progress, allowing for highly intricate designs and producing parts with greater speed and accuracy.

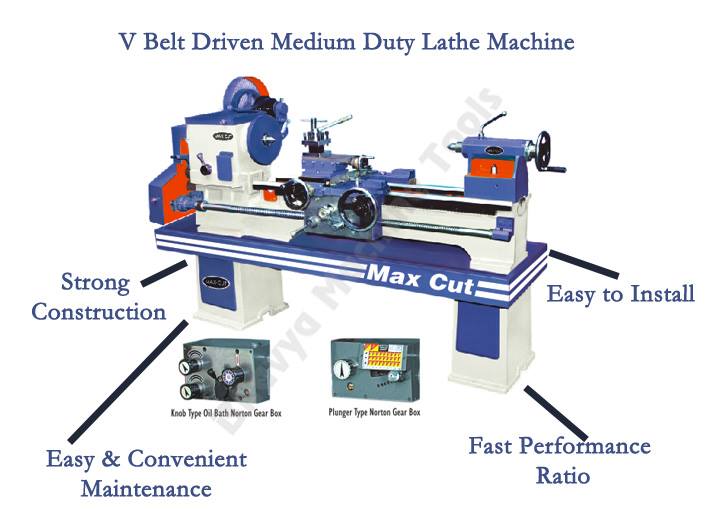

Advance Lathe Machines – Features & Benefits

Features

A CNC lathe is an advanced light-duty all geared lathe machine designed to adapt the modern version of tooling and processes. In the dro lathe machine, metal parts are shaped by utilizing different machine tools. A turret machine is used to hold the indexes. In addition to all features, the slides present in the turret lathe allows the movement of metal parts in multiple axes.

Benefits

The major benefit of toolroom lathe is that even the extremely detailed parts or components can be made using the specific CNC lathe machining techniques. The setup of the mini bench lathe machine is done easily. The CNC lathe machines can automatically work with the help of computer guidance. The major benefit of the high-speed precision lathe is that it can be used for mass production. All above are the various points about a brief history of the lathe machine.